VACUUM CHAMBER INSPECTION [13B-MSP]

id0113z3705700

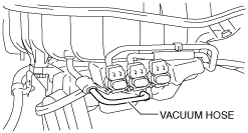

Vacuum Hold Inspection

1. Remove the extension manifold and oil filler pipe. (See INTAKE-AIR SYSTEM REMOVAL/INSTALLATION [13B-MSP].)

2. Remove the vacuum hose.

3. Install the vacuum pump as shown in the figure.

4. Inspect using the following procedure:

- (1) Apply vacuum until it reaches −60 kPa {−450 mmHg, −18 inHg}.

- (2) If it reaches −60 kPa {−450 mmHg, −18 inHg}, stop applying vacuum.

- (3) Verify the displayed vacuum after 10 s.

-

-

Standard

-

−60 —−50 kPa {−450 —−375 mmHg, −18 —−15 inHg}

-

• If it is not within the specification, inspect the check valve. (See

Check valve.)

Check valve

1. Remove the check valve.

2. Install the vacuum pump as shown in the figure.

3. Inspect using the following procedure:

- (1) Apply vacuum until it reaches −60 kPa {−450 mmHg, −18 inHg}.

- (2) If it reaches −60 kPa {−450 mmHg, −18 inHg}, stop applying vacuum.

- (3) Verify the displayed vacuum after 10 s.

-

-

Standard

-

−60 —−50 kPa {−450 —−375 mmHg, −18 —−15 inHg}

-

• If not within the specification, replace the check valve.

• If it is within the specification, inspect the solenoid valve. (See

Solenoid valve.)

Solenoid valve

1. Remove the filter caps from two of the solenoid valves and install blind caps (1010-13104) to the removed positions.

2. Install the vacuum pump as shown in the figure.

3. Inspect using the following procedure:

- (1) Apply vacuum until it reaches −60 kPa {−450 mmHg, −18 inHg}.

- (2) If it reaches −60 kPa {−450 mmHg, −18 inHg}, stop applying vacuum.

- (3) Verify the displayed vacuum after 10 s.

-

-

Standard

-

−60 —−50 kPa {−450 —−375 mmHg, −18 —−5 inHg}

4. Perform the same inspection for the remaining two solenoid valves.

-

• Replace the solenoid valve which is not within the specification.

• If all of the solenoid valves are not within the specification, replace the oil filler pipe as a single component.