REVERSE AND HIGH CLUTCH DRUM INSPECTION

BHE051319500A07

Drive Plate Inspection

1. Measure the facing thickness in three places and calculate the average.

-

• If it is less than the minimum specification, replace the drive plate.

-

Standard

-

2.0 mm {0.079 in}

-

Minimum

-

1.8 mm {0.071 in}

Return Spring Inspection

1. Measure the spring specification.

-

• If not as specified, replace the return spring.

Specification

|

Outer diameter (mm {in})

|

Free length (mm {in})

|

No. of coils

|

Wire diameter

(mm {in})

|

|

8.0 {0.315}

|

27.1 {1.067}

|

10.2

|

1.1 {0.043}

|

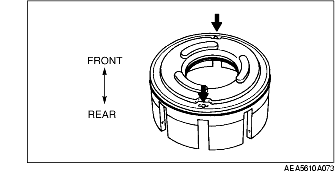

Reverse Clutch Piston Inspection

-

Warning

-

• Using compressed air can cause dirt and other particles to fly out, causing injury to the eyes. Wear protective eye wear whenever using compressed air.

1. Verify that there is airflow when applying compressed air through the fluid passage of the reverse clutch piston.

-

• If there is any malfunction, replace the reverse clutch piston.

-

Air pressure

-

390 kPa {4.0 kgf/cm2, 57 psi} max.

|

Front to rear

|

Airflow

|

|

Rear to front

|

Non airflow

|