• A one-piece, double-jointed propeller shaft has been adopted for all models. For MT vehicles, a lightweight propeller shaft, with a carbon fiber-reinforced resin pipe*, has been adopted. Due to this, oscillation is controlled and noise vibration and harshness have been greatly reduced over a wide range.

Additionally, a weight reduction of approx. 3.7 kg {130 oz} has been achieved. (Compared to a two piece, steel-construction propeller shaft)

• Due to the elimination of crease angle in the universal joint together with an in-line layout when viewed from any angle for the powertrain (transmission, propeller shaft, and differential), booming noise has been supressed, and vibration and harsh noise have been greatly reduced.

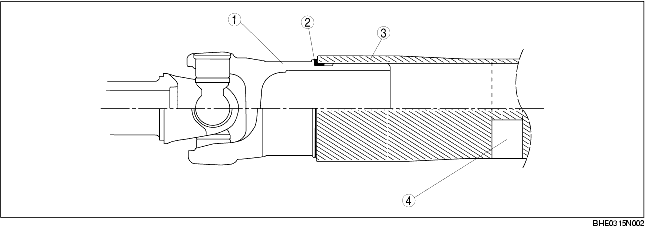

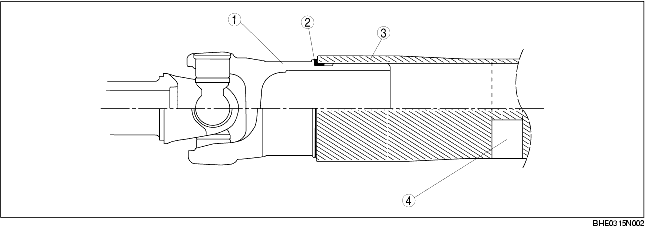

A crimped-fixing method has been adopted for the universal joint.