1. Inspect the speedometer by setting it to check code 12 of the input/output check mode.(See INSTRUMENT CLUSTER INPUT/OUTPUT CHECK MODE.)

1. Adjust the tire pressure to the specification.

2. Using a speedometer tester, verify that the tester reading is as indicated in the table below.

|

Speedometer tester indication (km/h)

|

Allowable range (km/h)

|

|---|---|

|

20

|

20-23

|

|

40

|

40-43

|

|

60

|

60-63

|

|

80

|

80-83

|

|

100

|

100-103

|

|

120

|

120-123

|

|

140

|

140-143

|

|

Speedometer tester indication (mph)

|

Allowable range (mph)

|

|---|---|

|

10

|

10-13

|

|

20

|

20-23

|

|

30

|

30-33

|

|

40

|

40-43

|

|

50

|

50-53

|

|

70

|

70-73

|

|

80

|

80-83

|

3. Verify that the speedometer reading is within the range indicated in the table.

1. Inspect the tachometer by setting it to check code 13 of the input/output check mode.(See INSTRUMENT CLUSTER INPUT/OUTPUT CHECK MODE.)

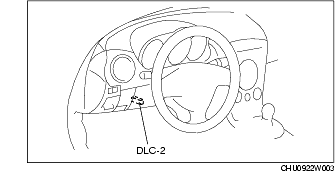

1. Connect the WDS or external diagnostic equipment to the diagnostic connector 2 (16-pin).

2. Compare the data monitor item (RPM) with the tachometer indication.

1. Inspect the fuel gauge by setting it to check code 23 of the input/output check mode.(See INSTRUMENT CLUSTER INPUT/OUTPUT CHECK MODE.)

1. Inspect the water temperature gauge by setting it to check code 25 of the input/output check mode.(See INSTRUMENT CLUSTER INPUT/OUTPUT CHECK MODE.)

1. Inspect the oil pressure gauge by setting it to check code 28 of the input/output check mode.(See INSTRUMENT CLUSTER INPUT/OUTPUT CHECK MODE.)