1. Align the bearing cover with guide bolts as shown.

2. Press the bearing cover in using the SST.

3. Remove the guide bolts and install the bearing cover installation bolts.

4. Mount the converter housing onto the SST (transaxle hanger).

5. Remove the bearing race and adjustment shims from the bearing housing using a pin punch and a hammer.

6. Set the output gear into the converter housing.

7. Install the bearing race removed in Step 5 to the selector, and install the selector and bearing race to the output gear.

8. Turn the selector to eliminate the gap between its two halves.

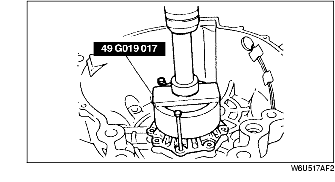

9. Set the SST (collars) in the position shown.

10. Set the bearing housing on the SST (selector) and install the SST (bolts). Tighten the bolts to the specified torque.

11. Turn the SST (selector) to increase the clearance (arrow) with the SST (bars) until it no longer turns.

12. Turn the selector in the opposite direction until the preload is eliminated (gap is reduced).

13. Mount the SSTs and a pull scale or a torque wrench on the output gear.

14. Adjust the clearance of the SST (selector) to obtain the specified preload/pull scale reading.

15. Measure the gap between A and B around the circumference of the SST (selector) using a feeler gauge.

16. Take the maximum reading and determine the shims to be used. Use no more than one shim.

Thickness of shim

17. Remove the bearing housing and the SST.

18. Install the required shims and press the bearing race into the bearing housing using the SST.

19. Install the output gear and idler gear.

20. Install the bearing housing.

21. Verify that the preload/pull scale reading is within the specification.

22. Remove the bearing housing and output gear component.