|

PID/DATA MONITOR INSPECTION[LA4AX-EL (CD4E)]

id050207805600

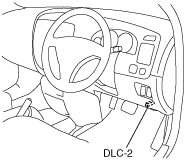

1. Connect the M-MDS to the DLC-2.

atraaw00000075

|

2. After the vehicle is identified, select the following items from the initial screen of the M-MDS.

3. Select the PID from the PID table.

4. Verify the PID data according to the directions on the screen.

PID/DATA MONITOR AND RECORD function table

|

Monitor item |

Definition |

Unit/Condition |

PCM terminal |

|---|---|---|---|

|

CCS

|

3-2 timing/coast clutch solenoid

|

On/Off

|

20

|

|

kPa

|

20

|

||

|

CCSV

|

3-2 timing/coast clutch solenoid control signal voltage

|

V

|

20

|

|

EPC

|

Electronic presser control solenoid

|

kPa

|

81

|

|

EPCV

|

Electronic presser control solenoid control signal voltage

|

V

|

81

|

|

GEAR

|

Selected gear (Calculated from shift solenoids A and B)

|

1/2/3/4

|

–

|

|

GEAR_MAX

|

No.1 gear candidate

|

–

|

–

|

|

GEAR_RAT

|

Gear ratio

|

–

|

–

|

|

OSS

|

Output shaft speed

|

RPM

|

84

|

|

OSS_SRC

|

Output shaft speed

|

RPM

|

84

|

|

SSA/SS1

|

Shift solenoid A

|

On/Off

|

6

|

|

SSA/SS1_F

|

Shift solenoid A status

|

Yes Fault/No Fault

|

–

|

|

SSB/SS2

|

Shift solenoid B

|

On/Off

|

11

|

|

SSB/SS2_F

|

Shift solenoid B status

|

Yes Fault/No Fault

|

–

|

|

TC_SLIPACT

|

Actual torque converter slip value

|

RPM

|

–

|

|

TC_SLIPDSD

|

Expected torque converter slip value

|

RPM

|

–

|

|

TCC

|

Torque converter clutch control solenoid

|

%

|

54

|

|

Engaged/Modulated/OFF

|

54

|

||

|

TCC_F

|

Torque converter clutch control solenoid status

|

Yes Fault/No Fault

|

–

|

|

TCC_RAT

|

Transaxle slip ratio

|

–

|

–

|

|

TCIL

|

O/D OFF indicator light

|

On/Off

|

–

|

|

TCS

|

O/D OFF switch

|

Not Depressed/Depressed

|

29

|

|

TFT

|

Transaxle fluid temperature

|

°C

|

37

|

|

V

|

37

|

||

|

TFT_F

|

Transaxle fluid temperature status

|

Yes Fault/No Fault

|

37

|

|

TR

|

Transaxle range

|

D/R/OD/

Man 2/Man 1/

P/N

|

64

|

|

TR_F

|

Transaxle range status

|

Yes Fault/No Fault

|

64

|

|

TR_V

|

Transaxle range signal voltage

|

V

|

64

|

|

TRAN_RAT

|

Transaxle gear ratio

|

–

|

–

|

|

TSS

|

Turbine shaft speed

|

RPM

|

59

|

|

TSS/ISS

|

Input shaft speed

|

RPM

|

59

|

|

TSS_SRC

|

Turbine shaft speed

|

RPM

|

59

|

|

TSSFM

|

TSS sensor failure mode

|

Yes Fault/No Fault

|

59

|

Simulation Function Procedure

1. Connect the M-MDS to the DLC-2.

atraaw00000075

|

2. After the vehicle is identified, select the following items from the initial screen of the M-MDS.

3. Select the simulation items from the PID table.

4. Perform the simulation function, inspect the operations for each parts.

Simulation item table

|

Simulation item |

Applicable component |

Unit/Condition |

PCM terminal |

|---|---|---|---|

|

CCS

|

3-2 timing/coast clutch solenoid

|

On/Off

|

20

|

|

kPa

|

20

|

||

|

EPC

|

Electronic presser control solenoid

|

kPa

|

81

|

|

SSA/SS1

|

Shift solenoid A

|

On/Off

|

6

|

|

SSB/SS2

|

Shift solenoid B

|

On/Off

|

11

|

|

TCC

|

Torque converter clutch control solenoid

|

%

|

54

|

|

Engaged/Modulated/OFF

|

54

|