CLOCK SPRING REMOVAL/INSTALLATION

id081000802000

Removal

-

Warning

-

• Always wear safety glasses when repairing an air bag equipped vehicle and when handling an air bag module. This will reduce the risk of injury in the event of an accidental operation (deployment).

• Carry a live air bag module with the air bag pointed away from your body. This will reduce the risk of injury in the event of an accidental operation (deployment).

• Do not set a live air bag module down with the deployment side face down. This will reduce the risk of injury in the event of an accidental operation (deployment).

• After operation (deployment), the air bag surface can contain deposits of sodium hydroxide, a product of the gas generating combustion that is irritating to the skin. Wash your hands with soap and water afterward.

• Never probe the connectors on the air bag module with a tester. If it is probed directly, the operation (deployment) of the air bag could result in personal injury.

• Air bag modules with discolored or damaged trim covers must be installed new, not repainted.

• The air bag sensor is important for proper air bag system operation (deployment). If a vehicle equipped with an air bag is involved in a collision, inspect the sensor mounting bracket and wiring harness connectors for deformation. Replace and properly position the damaged sensors or any other structural components whether or not the air bag has operated (deployed).

• To avoid accidental operation (deployment) of the air bag and possible personal injury, always deplete the back-up power supply before repairing or replacing any front or side air bag structural component, and before servicing, replacing, adjusting, or causing impact to components near the air bag sensors, such as doors, dashboard, console, door latches, strikers, seats and bonnet latches.

• Before servicing, refer to this workshop manual to determine the location of the crash zone sensor.

• The side air bag sensors are located at or near the base of the B-pillar.

• To deplete the backup power supply, disconnect the battery negative cable and wait for 1 min or more. Be sure to disconnect auxiliary batteries and power supplies (if equipped).

• The SST (diagnostic simulator) is for air bag system servicing only. Before using the vehicle, it must be removed. Failure to remove it could result in personal injury and loss of vehicle safety standards.

-

Note

-

• If a seat equipped with a seat mounted side air bag or a pre-tensioner front buckle (if equipped) is being serviced the air bag system must be deactivated.

• The SST (diagnostic simulator) must be installed under the seats in the side air bag and pre-tensioner (if equipped) to floor connectors.

• Diagnostics or repairs are not to be performed on a side air bag system or a pre-tensioner (if equipped) with the seats in the vehicle. Prior to attempting to diagnose/repair the side air bag system or a pre-tensioner front buckle (if equipped) the seats must be removed from the vehicle and the SST (diagnostic simulator) must be installed in the side air bag and the pre-tensioner front buckle (if equipped) connectors at the floor connectors. The SST (diagnostic simulator) must be removed prior to operating the vehicle on the road.

• Diagnostics may be performed on seat systems other than the side air bag or pre-tensioner front buckle (if equipped) (lumbar, climate control, heat, power seat track) with the seat installed in the vehicle as long as the SSTs (diagnostic simulator) are installed under the seats in the side air bag and pre-tensioner front buckle to floor connectors.

• After diagnosing/repairing the seat system, always remove the SST (diagnostic simulator) before operating the vehicle on the road.

• Replace only with new parts. If the new part does not correct the malfunction, install the original part and perform the diagnostic procedure again.

1. Make sure the wheels are in the straight-ahead position.

2. Disconnect the negative battery cable and wait 1 min or more.

3. Remove the driver-side air bag module. (See DRIVER-SIDE AIR BAG MODULE REMOVAL/INSTALLATION.)

4. Remove the steering wheel.(See STEERING WHEEL AND COLUMN REMOVAL/INSTALLATION.)

-

Note

-

• For the steering wheel removal procedure, refer to the following items and procedures.

5. Position the steering column completely downward.

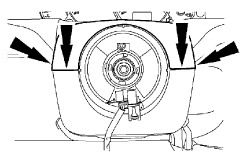

6. Push in where indicated, releasing the retaining tabs, and remove the upper steering column.

7. Remove the steering column lower cover.

- (1) Release the tilt column locking lever, if equipped.

-

- (2) Remove the three screws.

-

- (3) Remove the steering column lower cover.

-

-

Note

-

• The steering column must be in the raised position, with the tilt column lever released (if equipped), to remove the lower steering column shroud.

8. Apply two strips of masking tape across the clock spring to prevent accidental rotation when the air bag sliding contact is removed.

9. Separate the clock spring from the steering column.

- (1) Remove the screw.

-

- (2) Pull out and separate the clock spring from the steering column.

-

10. Remove the clock spring.

- (1) Disconnect the accessory connector.

-

- (2) Push to release the air bag connector locking clip.

-

- (3) Disconnect the air bag connector.

-

- (4) Remove the clock spring.

-

Installation

-

Warning

-

• Always wear safety glasses when repairing an air bag equipped vehicle and when handling an air bag module. This will reduce the risk of injury in the event of an accidental operation (deployment).

• Carry a live air bag module with the air bag and deployment side away from your body. This will reduce the risk of injury in the event of an accidental operation (deployment).

• Do not set a live air bag module down with the deployment side face down. This will reduce the risk of injury in the event of an accidental operation (deployment).

• After operation (deployment), the air bag surface can contain deposits of sodium hydroxide, a product of the gas generating combustion that is irritating to the skin. Wash your hands with soap and water afterward.

• Never probe the connectors on the air bag module with a tester. If it is probed directly, the operation (deployment) of the air bag could result in personal injury.

• Air bag modules with discolored or damaged trim covers must be installed new, not repainted.

• The air bag sensor orientation is critical for proper air bag system operation (deployment). If a vehicle equipped with an air bag is involved in a collision, inspect the sensor mounting bracket and wiring harness connectors for deformation. Replace and properly position the damaged sensors or any other structural components whether or not the air bag has operated (deployed).

• To avoid accidental operation (deployment) of the air bag and possible personal injury, always deplete the back-up power supply before repairing or replacing any front or side air bag structural component, and before servicing, replacing, adjusting, or causing impact to components near the air bag sensors, such as doors, dashboard, console, door latches, strikers, seats and bonnet latches.

• Before servicing, refer to this workshop manual to determine the location of the crash zone sensor.

• The side air bag sensors are located at or near the base of the B-pillar.

• To deplete the backup power supply, disconnect the battery negative cable and wait for 1 min or more. Be sure to disconnect auxiliary batteries and power supplies (if equipped).

• The SST (diagnostic simulator) is for air bag system servicing only. Before using the vehicle, it must be removed. Failure to remove it could result in personal injury and loss of vehicle safety standards.

-

Note

-

• If a seat equipped with a seat mounted side air bag or a pre-tensioner front buckle (if equipped) is being serviced, the air bag system must be deactivated.

• The SST (diagnostic simulator) must be installed under the seats in the side air bag and pre-tensioner front buckle (if equipped) to floor connectors.

• Diagnostics or repairs are not to be performed on a side air bag system or a pre-tensioner front buckle (if equipped) with the seats in the vehicle. Prior to attempting to diagnose/repair the side air bag system or a pre-tensioner front buckle (if equipped) the seats must be removed from the vehicle and the SST (diagnostic simulator) must be installed in the side air bag and the pre-tensioner front buckle (if equipped) connectors at the floor connectors. The SST (diagnostic simulator) must be removed prior to operating the vehicle on the road.

• Diagnostics may be performed on seat systems other than the side air bag or pre-tensioner front buckle (if equipped) (lumbar, climate control, heat, power seat track) with the seat installed in the vehicle as long as the restraint system diagnostic tools are installed under the seats in the side air bag and pre-tensioner front buckle to floor connectors.

• After diagnosing/repairing the seat system, always remove the SST (diagnostic simulator) before operating the vehicle on the road.

• Replace only with new parts. If the new part does not correct the malfunction, install the original part and perform the diagnostic procedure again.

1. Attach the SST (diagnostic simulator) to the vehicle wiring harness side of the clock spring connector at the steering column.

2. Connect the negative battery cable.

3. With the SST (diagnostic simulator) installed to all deployable devices, diagnose the air bag system.

4. Disconnect the negative battery cable and wait 1 min or more.

5. Remove the SST (diagnostic simulator) from the vehicle wiring harness side of the clock spring connector at the steering column.

6. Connect the clock spring connectors.

- (1) Connect the air bag connector.

-

- (2) Connect the accessory connector.

-

7. Align the clock spring for installation.

-

Note

-

• The clock spring is shown from the back for clarity.

- (1) Align the large slot to the large tab in the clock spring.

-

- (2) Align the small slot to the small tab in the clock spring.

-

8. Install the clock spring.

- (1) With the slots and tabs aligned, slide the clock spring over the steering column.

-

- (2) With the clock spring sitting flush against the multi-function switch, install the screws.

-

9. If reusing the same clock spring, remove the masking tape.

10. Install the lower steering column shroud.

- (1) Release the tilt column locking lever, if equipped.

-

- (2) Position the lower steering column shroud to the steering column.

-

-

Note

-

• The steering column must be in the raised position, with the tilt column lever released (if equipped), to install the lower steering column shroud.

- (3) Install the three screws.

-

11. Position the steering column completely downward.

12. Position the upper steering column shroud to the steering column and completely engage the retaining tabs.

- (1) Make sure the upper steering column shroud is aligned correctly and the retaining tabs are completely engaged.

-

13. Install the steering wheel.

(See STEERING WHEEL AND COLUMN REMOVAL/INSTALLATION.)

-

Note

-

• For the steering wheel installation procedure, refer to the following items or instructions.

14. Install the driver-side air bag module. (See DRIVER-SIDE AIR BAG MODULE REMOVAL/INSTALLATION.)

15. Verify that the SST (diagnostic simulator) is removed.

-

Warning

-

• The SST (diagnostic simulator) is for air bag system servicing only. Before using the vehicle, it must be removed. Failure to remove it could result in personal injury and loss of vehicle safety standards.