STEP

INSPECTION

ACTION

1

INSPECT HEADLIGHT RELAY

Disconnect the headlight relay connector.

Do the headlights go out?

Yes

Go to Step 4.

No

Go to the next step.

2

INSPECT HEADLIGHT RELAY

Inspect the headlight relay. (See RELAY INSPECTION.)

Is the headlight relay normal?

Yes

Go to the next step.

No

Replace the headlight relay.

3

INSPECT RELATED WIRING HARNESS FOR SHORT TO POWER SUPPLY

Disconnect the H/L-RH 15 A fuse.

Measure the voltage at the H/L-RH 15 A fuse.

Is the voltage more than 10 V?

Yes

Repair the related wiring harness.

No

Reconnect the headlight relay.

4

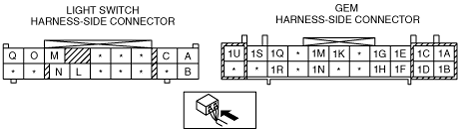

INSPECT GEM

Disconnect GEM connector.

Do the headlight go out?

Yes

Go to Step 6.

No

Go to the next step.

5

INSPECT RELATED WIRING HARNESS FOR SHORT TO GROUND

Measure the resistance between GEM terminal I and ground.

Is the resistance more than 10,000 ohms?

Yes

Replace the headlight relay.

No

Repair the related wiring harness.

6

INSPECT LIGHT SWITCH

Connect the GEM connector.

Disconnect the light switch connector.

Do the headlights go out?

Yes

Replace the light switch.

No

Go to the next step.

7

INSPECT RELATED WIRING HARNESS FOR SHORT TO GROUND

Measure the resistance between light switch terminal H and ground.

Is the resistance more than 10,000 ohms?

Yes

Go to the next step.

No

Repair the related wiring harness.

8

INSPECT GEM OPERATION

Disconnect all GEM connectors.

Inspect for the following items:

• Corrosion

• Terminal separation

Connect all the connectors and verify that their positions are correct.

Operate the system and inspect for any malfunction.

Is there any malfunction?

Yes

Replace the GEM.

Clear the DTC.

Repeat GEM DTC inspection.

No

The malfunction may result from loose connectors or corrosion.

Clear the DTC.

Repeat the DTC inspection.