CLUTCH COMPONENT INSPECTION

BUE051719500A03

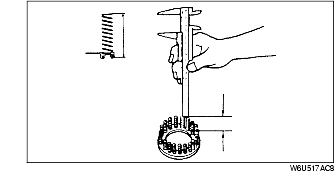

Drive Plate Inspection

1. Measure the facing thickness in three places and calculate the average value.

-

• If not within the specification, replace the drive plates.

-

Thickness

-

Standard: 1.6 mm {0.063 in}

-

Minimum: 1.5 mm {0.059 in}

Spring and Retainer Inspection

1. Measure the free length of the spring and inspect for deformation.

-

• If not within the specification, replace the spring and retainer.

-

Free length

-

31.54 mm {1.242 in}

Coasting Clutch Piston Inspection

-

Warning

-

• Using compressed air can cause dirt and other particles to fly out, causing injury to the eyes. Wear protective eye wear whenever using compressed air.

1. Verify that there is no air leakage when applying compressed air through the oil hole opposite the return spring.

2. Verify that there is air flow when applying compressed air through the oil hole on the return spring side.

-

• Replace the coasting clutch piston if it is damaged or malfunctioning.

-

Air pressure

-

390 kPa {4.0 kgf/cm2, 57 psi} max.

Reverse Clutch Piston Inspection

-

Warning

-

• Using compressed air can cause dirt and other particles to fly out, causing injury to the eyes. Wear protective eye wear whenever using compressed air.

1. Verify that there is no air leakage when applying compressed air through the oil hole opposite the return spring.

2. Verify that there is air flow when applying compressed air through the oil hole on the return spring side.

-

• Replace the reverse clutch piston if it is damaged or malfunctioning.

-

Air pressure

-

390 kPa {4.0 kgf/cm2, 57 psi} max.

Reverse and Forward Clutch Drum Inspection

1. Verify that there is no air leakage when applying compressed air through the oil hole on the piston side.

2. Verify that there is air flow when applying compressed air through the oil hole opposite the piston side.

-

• Replace the reverse and forward clutch drum if it is damaged or malfunctioning.

-

Air pressure

-

390 kPa {4.0 kgf/cm2, 57 psi} max.