|

1

|

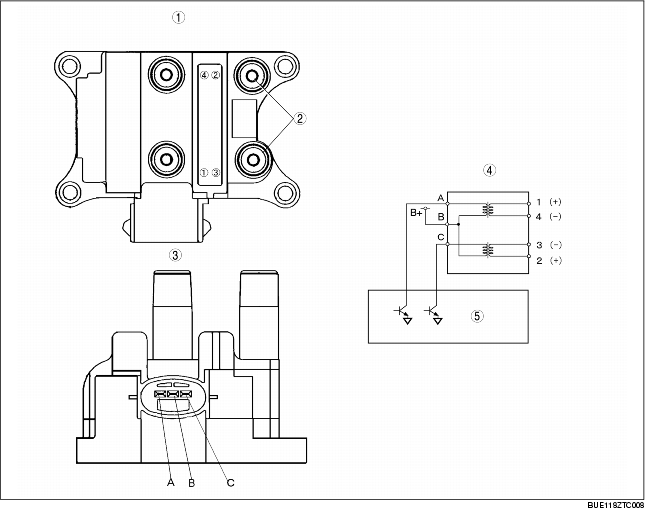

Ignition coil upper surface figure

|

|

2

|

Two secondary terminals

|

|

3

|

Ignition coil side view

|

|

4

|

Ignition coil

|

|

5

|

PCM

|

Terminal Layout

|

Terminal

|

Signal name

|

|

|---|---|---|

|

Three terminals

|

A

|

Ignition coil control signal 2 (No.1, No.4 cylinders)

|

|

B

|

Ignition coil power supply

|

|

|

C

|

Ignition coil control signal 1 (No.2, No.3 cylinders)

|

|