|

Calculation and determination method for fuel injection time and correction

|

Control zone

|

|

|

|

|

|

|

|

Injection time at start

|

Set value according to engine coolant temperature (low engine coolant temperature→long injection time)

|

*

|

|

|

|

|

|

Basic injection time

|

Basic injection time = charging efficiency x fuel flow coefficient

|

|

*

|

*

|

|

|

|

Fuel cut

|

Fuel injection time = 0

|

|

|

|

*

|

*

|

|

Ineffective injection time

|

Set time according to injector performance

|

|

*

|

*

|

|

|

|

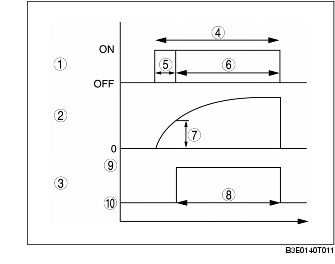

Volume increase correction at engine start

|

Purpose: Ensures engine speed stability just after engine start

Correction condition

• Specified time according to engine coolant temperature directly after engine start

Correction amount

• Low engine coolant temperature→large correction

• Low intake air temperature→large correction

|

x

|

x

|

|

|

|

|

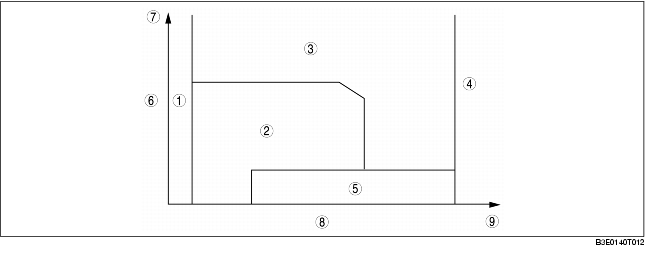

Feedback correction

|

Purpose: Controls air/fuel ratio to theoretical air/fuel ratio

Correction condition

• Engine coolant temperature is at set value or more

Correction amount

• HO2S electromotive force is approx. 0.45 V or more→volume decrease correction

• HO2S electromotive force is approx. 0.45 V or less→volume increase correction

|

|

x

|

|

|

|

|

D-range correction

|

Purpose: Ensures engine speed stability during D-range shifting

Correction condition

• Throttle valve is fully open and shifting in D range

Correction amount

• Low engine coolant temperature→large correction

|

|

x

|

|

|

|

|

Heavy load volume increase correction

|

Purpose: Improved engine output, decrease of exhaust gas temperature

Correction condition

• According to engine speed when the throttle valve opening angle is the fixed value or more, otherwise, according to engine speed and charging efficiency

Correction amount

• High engine speed, high charging efficiency→large correction

|

|

|

x

|

|

|

|

Warm-up volume increase correction

|

Purpose: Ensures combustion stability when engine coolant temperature is low

Correction condition

• While at set engine coolant temperature

Correction amount

• High charging efficiency, low engine coolant temperature→large correction

|

x

|

x

|

x

|

|

|

|

A/C and P/S increase correction

|

Purpose: Ensures engine speed stability during A/C and P/S operation

Correction condition

• A/C or P/S operating

Correction amount

• Low engine coolant temperature→large correction

|

|

x

|

x

|

|

|

|

Volume increase correction during acceleration

|

Purpose: Corrects fuel injection delay during acceleration, to ensure drive stability

Correction condition

• When acceleration amount (change in the amount of charging efficiency) is at the set value or more.

Correction amount

• Low engine coolant temperature→large correction

• Large acceleration amount→large correction

|

|

x

|

x

|

|

|

|

Deceleration volume increase correction

|

Purpose: Ensures engine speed stability after fuel cut and fuel cut recovery

Correction condition

• When suddenly entering deceleration fuel cut zone while driving with load, or recovery from fuel cut, the correction value is gradually increased to the set value

Correction amount

• After meeting deceleration fuel cut condition→volume decrease correction

• During fuel cut recovery→volume increase correction

|

|

|

|

|

x

|

|

Learning correction

|

Purpose: Corrects deviation in air/fuel ratio from deterioration over time of mechanical devices

Correction condition

• Under any condition except purge control

Correction amount

• Learning value based on average of feedback correction value

|

|

x

|

x

|

|

|