HEATED OXYGEN SENSOR (HO2S) CONSTRUCTION/OPERATION [L3 R.H.D.]

BUE014018860N02

|

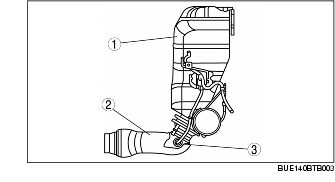

1

|

Exhaust manifold insulator

|

|

2

|

Front pipe

|

|

3

|

HO2S

|

• Installed directly behind the flexible joint.

• The built-in heater promotes activation of the heated oxygen sensor at engine start (when exhaust gas is at low temperature).

|

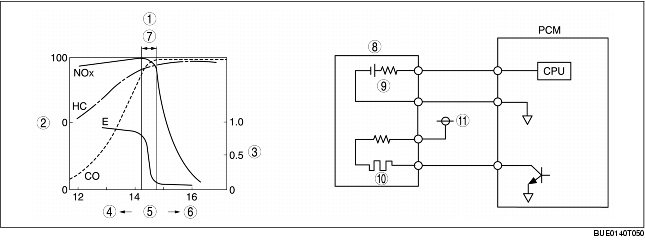

1

|

HO2S characteristic

|

|

2

|

HO2S output voltage

|

|

3

|

Time elapsed after cold-engine start

|

|

4

|

With heater

|

|

5

|

Without heater

|

|

6

|

Warming up

|

|

7

|

After warm up

|

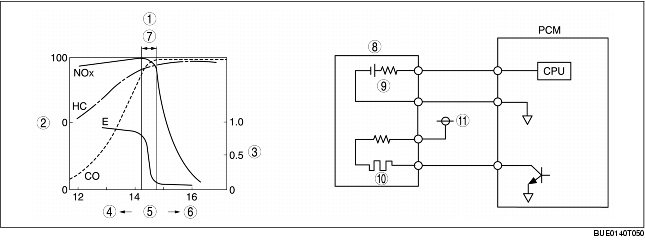

• A zirconium element is used on the sensor. When there is a difference between the oxygen concentration on both sides of the element, electromotive force is generated by the movement of oxygen ions.The electromotive force changes significantly at the boundary of the stoichiometric air/fuel ratio (A/ F=14.7). The PCM inputs the voltage generated from the HO2S directly, and increases or decreases the fuel injection amount by the fuel injection control so that it is close to the stoichiometric air/fuel ratio.

• When the temperature of the zirconium element is low, electromotive force is not generated. Therefore the HO2S is heated by a built-in heater, promoting the oxygen sensor activation. Due to this, the sensor is efficiently activated even immediately after cold-engine start, and a stable sensor output can be obtained.

|

1

|

HO2S characteristic

|

|

2

|

Purified percentage

|

|

3

|

HO2S electromotive force

|

|

4

|

Rich

|

|

5

|

Air/fuel ratio

|

|

6

|

Lean

|

|

7

|

Feedback control range

|

|

8

|

HO2S (built into heater)

|

|

9

|

HO2S

|

|

10

|

Heater

|

|

11

|

B+

|