MANUAL TRANSAXLE DESCRIPTION AND OPERATION [G15M-R, G25MX-R]

BUE051500000N16

Manual Transaxle

• The G15M-R and G25MX-R manual transaxle is a fully synchronized five-speed transaxle. The forward gears are selected by a synchronizer mechanism. 3rd gear, 4th gear and the 5th gear are mounted on the primary shaft. 1st gear, 2nd gear and the reverse secondary gear are mounted on the secondary shaft. The helical-cut forward gears are in constant mesh with the corresponding gears on the opposing shaft. The G15M-R and G25MX-R features a synchronized reverse gear. The reverse gears have straight-cut teeth and are engaged through the reverse idler gear and bushing.

External Shift Linkage

• The G15M-R and G25MX-R manual transaxle is controlled by a floor-mounted gearshift lever located in the console panel. The gearshift lever is attached to the transaxle case through the extension bar. Gearshift lever movements are transferred through the change control rod.

Internal Shift Linkage

• The G15M-R and G25MX-R manual transaxle is shifted internally by three shift forks. The 5th and reverse gear shift fork shifts in and out of the 5th and reverse gears. The 1st/2nd and the 3rd/4th shift forks control all other forward gear shifts.

Reverse Gear

• The reverse idler gear and bushing is mounted on a reverse idler gear shaft supported at one end in the clutch housing and at the other in the transaxle case. Because the reverse idler gear and bushing slides and rotates on the reverse idler gear shaft, the bushing is necessary to prevent metal-to-metal contact and wear.

• When the reverse idler gear and bushing slides on the reverse idler gear shaft, it engages the reverse drive gear on the primary shaft and the reverse gear on the secondary shaft. The driving gear is part of the primary shaft and the reverse gear is machined on the outside diameter of the 1st/2nd synchronizer sleeve.

• When the reverse idler gear and bushing rotates on the reverse idler gear shaft, it reverses the power flow to the secondary shaft.

• To engage the reverse idler gear and bushing, the motion of the shift fork selector lever is transferred to the reverse gearshift lever through the shift gate. The reverse gearshift lever is mounted on a meshlock plunger that allows it to act as a fulcrum. When the 5th/reverse gearshift selector arm moves its end of the shift fork selector lever, the opposite end slides the reverse idler gear and bushing into engagement with the primary shaft and secondary shaft reverse gears.

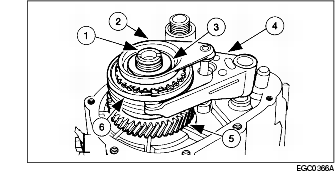

|

1

|

Primary shaft

|

|

2

|

Primary reverse synchronizer cone

|

|

3

|

Reverse synchronizer gear sleeve

|

|

4

|

5th/reverse shift fork

|

|

5

|

5th gear

|

|

6

|

5th synchronizer ring

|

• The G15M-R and G25MX-R uses a primary reverse synchronizer cone mounted to the primary shaft above the 5th gear. When the transaxle is engaged in reverse, the 5th gear synchronizer hub is pressed against the primary reverse synchronizer cone, which is pressed against the reverse synchronizer gear sleeve. This sleeve is connected to the primary shaft. As the primary reverse synchronizer cone surface engages the cone surface of the sleeve, it stops rotation of the primary shaft and allows the smooth meshing of the reverse idler and the reverse gear.