VARIABLE INTAKE AIR SOLENOID VALVE INSPECTION [L3 R.H.D.]

id0113a2802800

Variable Intake Air Control Inspection

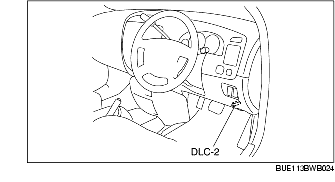

1. Connect the WDS or equivalent to the DLC-2.

2. Using PID/data monitoring function, monitor the following PCM input signal.

-

• RPM

-

Note

-

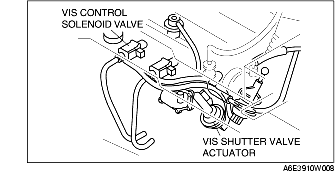

• Since the variable intake air shutter valve actuator rod has a cover, the rod cannot be detected visually from the outer-side. Therefore, when inspecting the actuator, verify the movement of the rod using a mirror inserted from under the actuator.

3. When the engine speed is approx. 4,750 rpm or less, verify that the variable intake air shutter valve actuator rod is pulled.

-

• If it does not operate, inspect the following:

-

(1) When the rod does not operate under any condition

-

1) Turn the ignition switch to the ON position.

-

2) Verify the operation sound of the variable intake air solenoid valve using the simulation function "IMTV."

-

• If the operation sound can be confirmed, inspect for the following:

-

- Vacuum hose disconnection or damage (intake manifold- variable intake air solenoid valve- variable intake air shutter valve actuator)

-

- Variable intake air shutter valve actuator

-

• If the operation sound cannot be verified, inspect the following:

-

- Variable intake air solenoid valve

-

- Wiring harnesses, connectors: open circuit (main relay- variable intake air solenoid valve-PCM)

-

(2) Rod operates under any condition

-

1) Turn the ignition switch to the ON position.

-

2) Using the simulation function "IMTV", verify the operation sound of the variable intake air solenoid valve.

-

• If the operation sound can be confirmed, inspect the following:

-

- Variable intake air shutter valve actuator

-

• If the operation sound cannot be verified, inspect the following:

-

- Variable intake air solenoid valve

-

- Wiring harnesses, connectors: open circuit (variable intake air solenoid valve-PCM)

-

(3) If the operation range is different

-

• PCM terminal voltage (using a PID/data monitor function)

-

- MAF

Airflow Inspection

1. Disconnect the negative battery cable.

2. Remove the variable intake air solenoid valve.

3. Inspect for airflow between the ports under the following condition.

-

• If it is within the specification, inspect for the related harnesses.

-

• If it is not within the specification, replace the variable intake air solenoid valve.

Standard

|

Measurement condition

|

Airflow

|

|

Between ports A-B

|

Between ports B-C

|

|

Apply B+ to terminal A, and connect terminal B to ground

|

Airflow detected

|

No airflow

|

|

Apply B+ to terminal A, and not connecting terminal B to ground

|

Airflow detected

|

No airflow

|