IDLE AIR CONTROL (IAC) VALVE INSPECTION [L3 R.H.D.]

id0113a2819700

Idle Air Control Inspection (Coolant Temperature Correction Inspection)

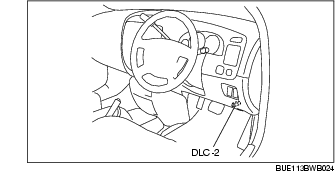

1. Connect the WDS or equivalent to the DLC-2.

2. Using PID/data monitor function, monitor the following PCM input/output signal.

-

• ARPMDES

-

• ECT

-

• IAC

-

• RPM

3. Start the engine while it is cold.

4. Verify that the engine is not idling roughly (low engine speed).

-

• If the engine is idling roughly, perform the following:

-

- If the engine speed is not within ±50 rpm of the target idle speed, inspect the following:

-

• IAC valve for stuck or not operating smoothly

-

- If the ECT, IAC is an abnormal value, inspect the following.

-

• PCM input signal circuit for coolant temperature signal

5. Verify that the engine speed gradually decreases according to the engine warming up.

-

• If the engine speed decrease cannot be confirmed, inspect the following:

-

- If the engine speed is not within ±50 rpm of the target idle speed, inspect the following:

-

• Throttle cable for stuck or pulled out

-

• IAC valve for stuck or not operating smoothly

-

- If either the ECT or IAC is an abnormal value, inspect the following:

-

• PCM input signal circuit for coolant temperature signal

Idle Air Control Inspection (Load Correction Inspection)

1. Connect the WDS or equivalent to the DLC-2.

2. Warm up the engine and idle.

3. Using the "IAC" simulation function, operate IAC valve with the 100% duty value, verify that the engine speed increases.

-

• If the engine speed does not change, inspect the IAC valve for stuck and rough operation.

4. Using PID/data monitor function, monitor the following PCM input/output signal.

-

• AC_REQ

-

• ARPMDES

-

• IAC

-

• PSP

-

• RPM

5. Verify that the engine speed is within the specification when each load is applied referring to the table below. (Except for the rotation decrease right after the load is operated.)

-

• If it is not within the specification, inspect for the following.

-

- If the target idle speed is within the specification and engine speed is not within the specification, inspect the IAC valve for stuck and rough operation.

-

- If both the target idle speed and engine speed is not within the specification, inspect for the input signal circuit displaying abnormal value in the monitoring items in Step 4.

Standard

|

Load condition

|

Idle speed (rpm)

|

|

P, N position

|

|

No load

|

600- 700

|

|

Electronic load on *1

|

650- 750

|

|

P/S operating

|

650- 750

|

|

A/C on

|

650- 750

|

-

*1 :

When headlight rear defroster, blower fan, main fan, and additional fan are all operated.

Resistance Inspection

1. Disconnect the negative battery cable.

2. Disconnect the IAC valve connector.

3. Using a tester, measure the resistance between IAC valve A-B terminals.

-

• If it is within the specification, inspect for the related wiring harnesses.

-

• If it is not within the specification, replace the IAC valve.

-

Standard

-

8.8-10.6 ohms [20 °C {68 °F}]