EGR VALVE INSPECTION [AJ (3.0L Duratec)]

id0116a1801100

EGR Control Inspection

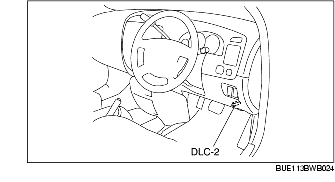

1. Connect the WDS or equivalent to the DLC-2.

2. Perform the KOER self-test and verify if DTC P0401, P0402, P1400, P1401, P1405, P1406, P1408, or P1409 is present.

-

• If DTC P0401, P0402, P1400, P1401, P1405, P1406, P1408, or P1409 is present, perform the applicable DTC inspection. (See DTC TABLE [AJ (3.0L Duratec)].)

3. Turn the ignition switch on.

4. Verify that the operation sound of the EGR control valve varies according to the duty value change when the duty value is increased using the simulation function EGRVR.

-

• If any operation sound changes cannot be verified, inspect the following and repair or replace any malfunctioning parts.

-

- EGR control valve (closed or stuck closed)

-

- Open or short circuit in wiring harness between EGR control valve terminal 2 and PCM terminal 47

-

- Open circuit in wiring harness between EGR control valve terminal 1 and main relay terminal 87

5. Disconnect the vacuum hose from the EGR valve.

6. Connect the hand vacuum gauge to the EGR valve.

7. Start the engine and idle it.

8. Monitor the DPFEGR, RPM PID.

9. Verify that the DPFEGR PID value increases when the duty value is increased up to about 40% using the simulation function EGRVR PID. If the engine is likely to stall, set the rpm at 1,000 rpm using the throttle.)

-

• If the DPFEGR PID value does not increase, inspect the following items.

-

- EGR valve sticking

-

- Clogging, damage, or improper connection of the vacuum hose between the EGR control valve and EGR valve

-

- DPFEGR sensor malfunction

-

- Clogging or disengagement of the pressure hose between the orifice valve and differential pressure feedback EGR sensor

-

- Orifice valve clogging

Inspection

1. Connect the WDS or the equivalent.

2. Disconnect the vacuum hose from the EGR valve and plug the hose.

3. Install the vacuum pump to the EGR valve.

4. Start the engine and idle it.

5. Access the following PIDs using the WDS or equivalent.

-

• DPFEGR (differential pressure feedback EGR sensor output voltage), RPM (engine speed)

6. Gradually apply vacuum to the EGR valve using the vacuum pump and verify that the DEFEGR PID value is as indicated in the following table.

-

• If the DEFEGR PID is not as indicated in the following table, replace the EGR valve.

-

EGR valve characteristics standards

|

Vacuum applied to EGR valve

|

DEFEGR PID value

|

|

Approx. 5.4 kPa

|

Starts increasing (EGR valve starts opening)

|

|

Gradually apply vacuum

|

Gradually increases

|

|

27-34 kPa

|

2.5 V or more

|

|

Keep applying 27-34 kPa for about 10 s

|

Constant voltage (Voltage does not lower within several seconds)

|