PURGE SOLENOID VALVE INSPECTION [L3 R.H.D.]

id0116a2800900

Evaporative Purge Control Inspection

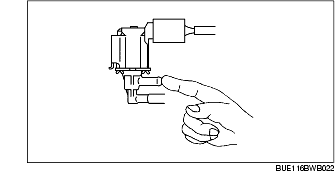

Without using WDS or equivalent

1. Disconnect the vacuum hose connected to the charcoal canister from the purge solenoid valve.

2. Start the engine and idle it.

3. Place your finger on the purge solenoid valve as shown in the figure and verify that vacuum is not applied while idling the engine from a cold start.

-

• If vacuum is applied, inspect the following.

-

- PCM terminal voltage

-

• Evaporative purge control signal

-

• Engine coolant temperature signal

-

- Purge solenoid valve

4. Run the vehicle on the chassis dynamometer and maintain the engine speed at approx. 2,000 rpm.

5. Verify that vacuum is applied after approx. 30 s.

-

• If vacuum cannot be confirmed, inspect the following.

-

- PCM terminal voltage

-

• Intake air temperature signal

-

• Evaporative purge control signal

-

• Throttle opening signal

-

• Load/no load detection signal

-

- Purge solenoid valve

Using WDS or equivalent

1. Disconnect the vacuum hose connected to the charcoal canister from the purge solenoid valve.

2. Connect the WDS or equivalent to the DLC-2.

3. Monitor the PID ECT.

4. Start the engine and idle it.

5. Place your finger onto the purge solenoid valve as shown in the figure and verify that vacuum is not applied when the PID ECT is 70 ×C {158 ×F} or less.

-

• If vacuum is applied, inspect for the following.

-

- PCM terminal voltage

-

• Evaporative purge control signal

-

• Engine coolant temperature signal

-

- Purge solenoid valve

6. Disconnect the vacuum hose.

7. Using the "EVAPCP" simulation function, set the current 0% duty value of the purge solenoid valve to the 100% duty value and operate to verify that the engine rough idles or the engine stops.

-

• If the idling condition does not change, inspect for the following.

-

(1) Turn the ignition switch to the ON position.

-

(2) Using the "EVAPCP" simulation function, set the present 0% duty value of the purge solenoid valve to the 50% duty value and verify the purge solenoid valve operation sound.

-

• If the operation sound is confirmed, inspect for the following.

-

- Vacuum hose disconnection or damage (intake manifold-purge solenoid valve-charcoal canister)

-

- Wiring harness, connectors: open circuit (main relay-purge solenoid valve-PCM)

-

• If the operation sound cannot be confirmed, inspect for the following.

-

- Purge solenoid valve

Airflow inspection

1. Disconnect the negative battery cable.

2. Remove the purge solenoid valve.

3. Inspect the airflow between the ports under the following conditions:

-

• If it is within the specification, inspect the related harnesses.

-

• If it is not within the specification, replace the purge solenoid valve.

Standard

|

Measurement condition

|

Airflow

|

|

Between ports A-B

|

Between ports B-C

|

|

• Apply B+ to terminal A, and connect terminal B to ground.

|

Airflow detected

|

• No airflow

|

|

Not applied B+ to terminal A, or terminal B not connected to ground.

|

No airflow

|

Airflow detected

|