CRANKSHAFT POSITION (CKP) SENSOR REMOVAL/INSTALLATION [L3]

id0140a7800600

Removal

1. Disconnect the negative battery cable.

2. Perform the following procedure for easier access.

-

(1) Remove the RH front tire.

-

(2) Remove the RH splash shield.

3. Disconnect the CKP sensor connector.

4. Remove the installation bolts, and then remove the CKP sensor.

Installation

-

Caution

-

• Do not allow foreign material such as iron filings to adhere to the sensor when replacing the CKP sensor. If it is installed with foreign material adhering, the sensor output signal will malfunction resulting from fluctuation in magnetic flux and cause a deterioration in engine control.

-

• Do not install the CKP sensor using any procedure other than the following, or change its installation position. It will cause a deterioration in engine control such as ignition timing or fuel injection control.

1. Perform the following procedure so that piston No.1 is at TDC.

-

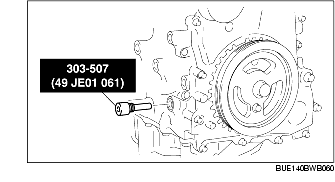

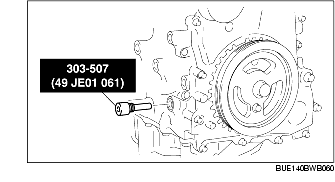

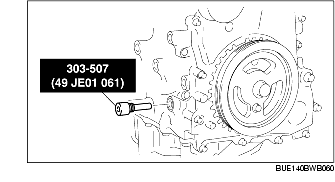

(1) Remove the cylinder block lower blind plug and install the SST.

-

(2) Rotate the crankshaft pulley clockwise until the crank weight contacts the SST so that piston No.1 is at TDC.

2. Using a ruler, mark the center line on the pulse wheel tooth (9th tooth counted counterclockwise from the toothgap).

-

Caution

-

• If the center line is not correct, it will cause a deterioration in engine control such as ignition timing or fuel injection control. Therefore mark the center line carefully.

3. Install the CKP sensor where the center line marked in Step 2 and the CKP sensor center line are aligned.

4. Install the CKP sensor installation bolts.

-

CKP sensor installation bolts tightening torque

-

5.5-7.5 N·m {56-76 kgf·cm, 49-66 in·lbf}

5. Remove the SST and install the blind plug.

-

Blind plug tightening torque

-

18-22 N·m {1.9-2.2 kgf·m, 14-16 ft·lbf}