SOLENOID VALVE INSPECTION [LA4AX-EL (CD4E)]

id0517a5801900

Resistance Inspection

-

Caution

-

• Liquid or foreign material penetrating the transaxle connector can cause a poor connection or corrosion. Be sure not to spill liquid or foreign material on the connector when disconnecting it.

1. Disconnect the negative battery cable.

2. Remove the battery and battery tray. (See BATTERY REMOVAL/INSTALLATION [YF (2.0L Zetec)].) (See BATTERY REMOVAL/INSTALLATION [L3, AJ (3.0L Duratec)].)

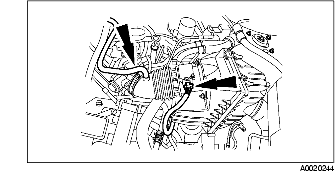

3. Disconnect the crankcase vent hose and MAF sensor connector.

4. Remove the air hose and air cleaner cover.

5. Remove the air cleaner component.

6. Disconnect the transaxle connector.

7. Measure the resistance between terminals.

-

• If not within the specification, inspect the wiring harness for continuity.

-

- If the harness is normal, replace the solenoid body component.

Standard Value

|

Terminal

|

Connection

|

Resistance (ohm)

|

|

A-D

|

Shift solenoid A (SSA)

|

12.0-22.0

|

|

D-G

|

Shift solenoid B (SSB)

|

12.0-22.0

|

|

D-I

|

3-2 timing/coast clutch solenoid (3-2T/CCS)

|

3.75-5.92

|

|

B-J

|

Torque converter clutch (TCC) solenoid

|

12.5-19.0

|

|

C-F

|

Electronic pressure control (EPC) solenoid

|

3.75-5.92

|

Operating Inspection

1. Disconnect the transaxle connector.

-

Caution

-

• Do not apply battery positive voltage to terminals for more than 3 s.

-

Note

-

• Because the operation sound of the valves is minimal, perform inspection in a quiet place.

2. Apply battery positive voltage to the following terminals and verify that operating sound is heard from the solenoid.

-

• If the "click" is not heard, inspect the transaxle harness for continuity.

-

- If the transaxle harness is normal, replace the solenoid body component.

|

Terminal

|

Connection

|

|

B+

|

GND

|

|

D

|

A

|

Shift solenoid A (SSA)

|

|

D

|

G

|

Shift solenoid B (SSB)

|

|

D

|

I

|

3-2 timing/coast clutch solenoid (3-2T/CCS)

|

|

B

|

J

|

Torque converter clutch (TCC) solenoid

|

|

F

|

C

|

Electronic pressure control (EPC) solenoid

|