|

STEP

|

INSPECTION

|

ACTION

|

|

1

|

Turn the ignition switch to the LOCK position.

Connect the WDS or the equivalent.

Turn the ignition switch to the ON position.

Using the WDS or equivalent, verify the DTCs and record the past malfunction DTCs.

Is the present malfunction DTC B1921 displayed?

|

Yes

|

-

Note

-

• Indicates a hard malfunction. The malfunction is still present. This malfunction cannot be cleared until it is corrected and the DTC is no longer displayed.

Go to the next step.

|

|

No

|

Intermittent malfunction. The malfunction is not present at this time. Go to Step 6.

|

|

2

|

Remove the SAS control module.

Visually inspect the installation surface of the SAS control module for any damage, corrosion, and foreign material.

Install the SAS control module installation bolts correctly, and verify that they are tightened to the specified tightening torque.

Is there any damage, corrosion, or foreign material on the installation surface of the SAS control module? Is there any malfunction in the installation bolts, or improper tightening torque?

|

Yes

|

Repair or reinstall the malfunctioning part, and go to Step 7.

|

|

No

|

Go to the next step.

|

|

3

|

Verify the SAS control module connectors are connected properly.

Are SAS control module connectors connected properly?

|

Yes

|

Go to the next step.

|

|

No

|

Connect the connectors properly, and go to Step 7.

|

|

4

|

Measure the resistance between the installation surface of the SAS control module and a normal body ground.

Is the resistance more than 100 ohms?

|

Yes

|

Repair the body ground. After repair, go to Step 7.

|

|

No

|

Go to the next step.

|

|

5

|

Turn the ignition switch to the LOCK position.

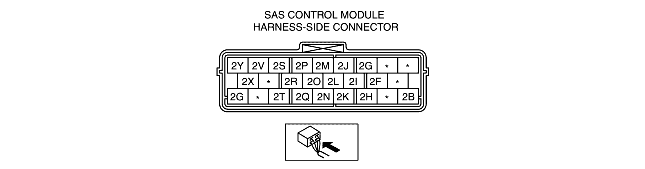

Disconnect SAS control module connector.

Measure the resistance between SAS control module terminal 2Q and body ground near the SAS control module installation area.

Is the resistance more than 100 ohms?

|

Yes

|

Repair the related wiring harness. After repair, go to Step 7.

|

|

No

|

Replace the SAS control module.

After replacement, go to Step 7.

|

|

6

|

Refer to the past malfunction DTCs recorded during Step 1.

Are the past malfunction DTCs displayed during Step 1 intermittent malfunctions which are not displayed as present malfunction DTCs?

|

Yes

|

Inspect for the cause of intermittent high resistance between SAS control module and body ground. Attempt to replicate the malfunction by flexing the wiring harness and cycling the ignition key between the ON and LOCK position repeatedly. Repair or replace if there is any intermittent malfunction.

After repair or replacement. go to the next step.

|

|

No

|

Go to the next step.

|

|

7

|

Refer to the past malfunction DTCs recorded during Step 1.

Was any past malfunction DTC displayed during Step 1?

|

Yes

|

If any DTC is displayed, refer to the DTC table, and repair the malfunctioning part according to the DTC inspection.

|

|

No

|

Refer to the reactivation procedure in the air bag system deactivation procedure, reactivate the system. Clear all DTCs.

|

|

|