DTC P0705

Digital transmission range (TR) sensor circuit malfunction (invalid bit pattern)

DTC P0708

Digital transmission range (TR) sensor circuit malfunction (TR3A circuit open)

DTC P1702

Digital transmission range (TR) sensor circuit intermittent

DTC P1704

Digital transmission range (TR) sensor circuit not indicating P or N position during on-board diagnostic

DTC P1705

Digital transmission range (TR) sensor circuit not indicating P or N position during on-board diagnostic

DETECTION CONDITION

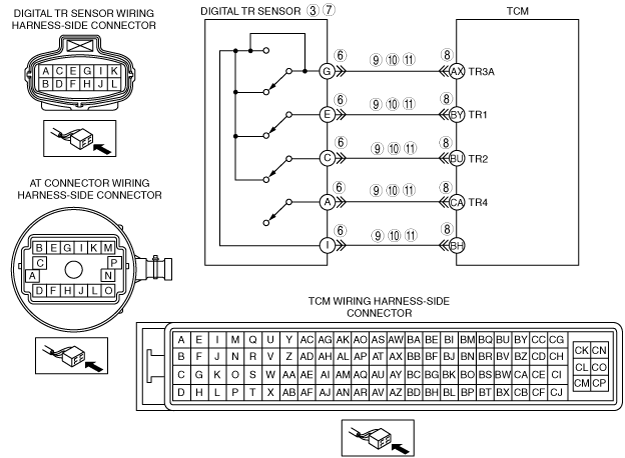

• P0705: Open circuit or short to ground in wiring harness between digital TR sensor terminal and TCM terminal or in digital TR sensor internal circuit (invalid bit pattern)

• P0708: Open circuit in wiring harness between digital TR sensor and TCM terminal or in digital TR sensor internal circuit (TR3 circuit)

• P1702: TCM cannot detect a signal from digital TR sensor

• P1704: PID TR_D not indicating P or N position, digital TR sensor or selector cable misalignment

• P1705: On-board diagnostic not performed in P or N position

POSSIBLE CAUSE

• Digital TR sensor malfunction

• Digital TR sensor or selector cable misadjustment

• Short to ground in wiring harness between digital TR sensor terminal G and TCM terminal AX

• Short to ground in wiring harness between digital TR sensor terminal E and TCM terminal BY

• Short to ground in wiring harness between digital TR sensor terminal C and TCM terminal BU

• Short to ground in wiring harness between digital TR sensor terminal A and TCM terminal CA

• Short to ground in wiring harness between digital TR sensor terminal I and TCM terminal BH

• Open circuit in wiring harness between digital TR sensor terminal G and TCM terminal AX

• Open circuit in wiring harness between digital TR sensor terminal E and TCM terminal BY

• Open circuit in wiring harness between digital TR sensor terminal C and TCM terminal BU

• Open circuit in wiring harness between digital TR sensor terminal A and TCM terminal CA

• Open circuit in wiring harness between digital TR sensor terminal I and TCM terminal BH

• Short to power supply in wiring harness between digital TR sensor terminal G and TCM terminal AX

• Short to power supply in wiring harness between digital TR sensor terminal E and TCM terminal BY

• Short to power supply in wiring harness between digital TR sensor terminal C and TCM terminal BU

• Short to power supply in wiring harness between digital TR sensor terminal A and TCM terminal CA

• Short to power supply in wiring harness between digital TR sensor terminal I and TCM terminal BH

• Damaged connectors between digital TR sensor and TCM

• TCM malfunction