DTC P0740

Torque converter clutch (TCC) control solenoid circuit malfunction (open circuit)

DTC P0741

Torque converter clutch (TCC) control solenoid circuit malfunction (stuck off)

DTC P0742

Torque converter clutch (TCC) control solenoid circuit malfunction (stuck on)

DTC P0743

Torque converter clutch (TCC) control solenoid circuit malfunction (open or short circuit)

DTC P0744

Torque converter clutch (TCC) control solenoid circuit malfunction (short to power)

DTC P1744

Torque converter clutch (TCC) control solenoid circuit malfunction (inoperative)

DETECTION CONDITION

• P0740: Open circuit in circuit between TCC control solenoid and TCM, or in TCC control solenoid internal circuit.

• P0741: Torque converter clutch slipping indicating a mechanical or hydraulic concern.

• P0742: Short to ground in circuit between TCC control solenoid and TCM, or in TCC control solenoid internal circuit.

• P0743: Open or short circuit in circuit between TCC control solenoid and TCM, or in TCC control solenoid internal circuit.

• P0744: Short to power supply in circuit between TCC control solenoid and TCM, or in TCC control solenoid internal circuit.

• P1744: Mechanical failure of TCC control solenoid.

POSSIBLE CAUSE

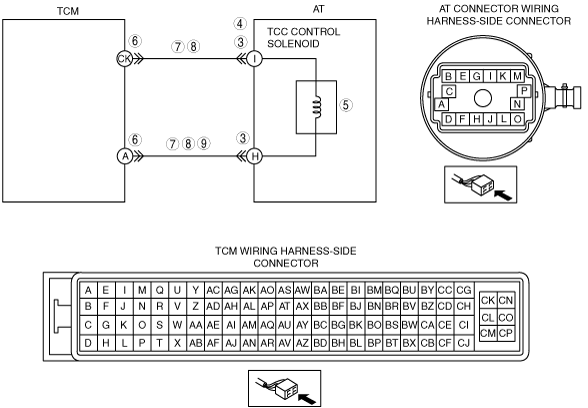

• TCC control solenoid malfunction.

• Short to ground in wiring harness between AT connector terminal I (wiring harness-side) and TCM terminal CK (wiring harness-side).

• Short to ground in wiring harness between AT connector terminal H (wiring harness-side) and TCM terminal A (wiring harness-side).

• Short to power supply in wiring harness between AT connector terminal H (wiring harness-side) and TCM terminal A (wiring harness-side).

• Open circuit in wiring harness between AT connector terminal I (wiring harness-side) and TCM terminal CK (wiring harness-side).

• Open circuit in wiring harness between AT connector terminal H (wiring harness-side) and TCM terminal A (wiring harness-side).

• Damaged connector between AT connector and TCM.

• TCM malfunction.