|

absggw00001190

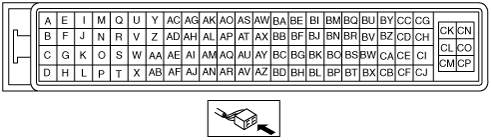

TCM INSPECTION [5R55S]

id0513c1250700

Terminal Voltage/Resistance Table (Reference)

absggw00001190

|

|

Terminal |

Signal |

Connected to |

Test Condition |

Voltage/Resistance |

Action |

|

|---|---|---|---|---|---|---|

|

A

|

TCC control solenoid control

|

TCC control solenoid

|

Inspect resistance between TCM terminals A and CK (wiring harness-side).

|

9—16 ohm

|

• Inspect the TCC control solenoid

• Inspect the related wiring harness

|

|

|

B

|

Shift solenoid A control

|

Shift solenoid A

|

Inspect resistance between TCM terminals B and CK (wiring harness-side).

|

16—45 ohm

|

• Inspect the shift solenoid A

• Inspect the related wiring harness

|

|

|

C

|

Shift solenoid B control

|

Shift solenoid B

|

Inspect resistance between TCM terminals C and CK (wiring harness-side).

|

16—45 ohm

|

• Inspect the shift solenoid B

• Inspect the related wiring harness

|

|

|

D

|

Shift solenoid D control

|

Shift solenoid D

|

Inspect resistance between TCM terminals D and CK (wiring harness-side).

|

16—45 ohm

|

• Inspect the shift solenoid D

• Inspect the related wiring harness

|

|

|

E

|

O/D OFF indicator output

|

Instrument cluster

|

Engine switch ON

|

B+

|

• Inspect the instrument cluster

• Inspect the related wiring harness

|

|

|

Engine switch OFF

|

Below 1.0 V

|

|||||

|

F

|

Shift solenoid C control

|

Shift solenoid C

|

Inspect resistance between TCM terminals F and CK (wiring harness-side).

|

16—45 ohm

|

• Inspect the shift solenoid C

• Inspect the related wiring harness

|

|

|

G

|

Selector position indicator signal 3

|

Instrument cluster

|

Inspect continuity between TCM and instrument cluster (wiring harness-side).

|

Continuity

|

• Inspect the related wiring harness

|

|

|

H

|

—

|

—

|

—

|

—

|

—

|

|

|

I

|

Pressure control solenoid A control

|

Pressure control solenoid A

|

Inspect resistance between TCM terminals I and CK (wiring harness-side).

|

3.3—7.5 ohm

|

• Inspect the pressure control solenoid A

• Inspect the related wiring harness

|

|

|

J

|

Pressure control solenoid B control

|

Pressure control solenoid B

|

Inspect resistance between TCM terminals J and CK (wiring harness-side).

|

3.3—7.5 ohm

|

• Inspect the pressure control solenoid B

• Inspect the related wiring harness

|

|

|

K

|

Selector position indicator signal 1

|

Instrument cluster

|

Inspect continuity between TCM and instrument cluster (wiring harness-side).

|

Continuity

|

• Inspect the related wiring harness

|

|

|

L

|

—

|

—

|

—

|

—

|

—

|

|

|

M

|

Pressure control solenoid C control

|

Pressure control solenoid C

|

Inspect resistance between TCM terminals M and CK (wiring harness-side).

|

3.3—7.5 ohm

|

• Inspect the pressure control solenoid C

• Inspect the related wiring harness

|

|

|

N

|

4x4 HI indicator output

|

Instrument cluster

|

Engine switch ON

|

B+

|

• Inspect the instrument cluster

• Inspect the related wiring harness

|

|

|

Engine switch OFF

|

Below 1.0 V

|

|||||

|

O

|

—

|

—

|

—

|

—

|

—

|

|

|

P

|

—

|

—

|

—

|

—

|

—

|

|

|

Q

|

Selector position indicator signal 2

|

Instrument cluster

|

Inspect continuity between TCM and instrument cluster (wiring harness-side).

|

Continuity

|

• Inspect the related wiring harness

|

|

|

R

|

4x4 LO indicator output

|

Instrument cluster

|

Engine switch ON

|

B+

|

• Inspect the instrument cluster

• Inspect the related wiring harness

|

|

|

Engine switch OFF

|

Below 1.0 V

|

|||||

|

S

|

—

|

—

|

—

|

—

|

—

|

|

|

T

|

—

|

—

|

—

|

—

|

—

|

|

|

U

|

Vehicle speed output

|

Instrument cluster

|

Inspect continuity between TCM and instrument cluster (wiring harness-side).

|

Continuity

|

• Inspect the related wiring harness

|

|

|

V

|

—

|

—

|

—

|

—

|

—

|

|

|

W

|

—

|

—

|

—

|

—

|

—

|

|

|

X

|

—

|

—

|

—

|

—

|

—

|

|

|

Y

|

—

|

—

|

—

|

—

|

—

|

|

|

Z

|

—

|

—

|

—

|

—

|

—

|

|

|

AA

|

—

|

—

|

—

|

—

|

—

|

|

|

AB

|

—

|

—

|

—

|

—

|

—

|

|

|

AC

|

—

|

—

|

—

|

—

|

—

|

|

|

AD

|

Output shaft speed (+)

|

OSS sensor

|

Inspect resistance between TCM terminals AD and AG (wiring harness-side).

|

325—485 ohm

|

• Inspect the OSS sensor

• Inspect the related wiring harness

|

|

|

AE

|

—

|

—

|

—

|

—

|

—

|

|

|

AF

|

—

|

—

|

—

|

—

|

—

|

|

|

AG

|

Output shaft speed (-)

|

OSS sensor

|

Inspect resistance between TCM terminals AD and AG (wiring harness-side).

|

325—485 ohm

|

• Inspect the OSS sensor

• Inspect the related wiring harness

|

|

|

AH

|

Turbine shaft speed (-)

|

TSS sensor

|

Inspect resistance between TCM terminals AH and AP (wiring harness-side).

|

325—485 ohm

|

• Inspect the TSS sensor

• Inspect the related wiring harness

|

|

|

AI

|

—

|

—

|

—

|

—

|

—

|

|

|

AJ

|

—

|

—

|

—

|

—

|

—

|

|

|

AK

|

System GND

|

GND

|

Under any condition

|

Continuity

|

• Inspect the related wiring harness

|

|

|

AL

|

—

|

—

|

—

|

—

|

—

|

|

|

AM

|

Intermediate shaft speed (-)

|

ISS sensor

|

Inspect resistance between TCM terminals AM and AS (wiring harness-side).

|

325—485 ohm

|

• Inspect the ISS sensor

• Inspect the related wiring harness

|

|

|

AN

|

—

|

—

|

—

|

—

|

—

|

|

|

AO

|

System GND

|

GND

|

Under any condition

|

Continuity

|

• Inspect the related wiring harness

|

|

|

AP

|

Turbine shaft speed (+)

|

TSS sensor

|

Inspect resistance between TCM terminals AH and AP (wiring harness-side).

|

325—485 ohm

|

• Inspect the TSS sensor

• Inspect the related wiring harness

|

|

|

AQ

|

—

|

—

|

—

|

—

|

—

|

|

|

AR

|

—

|

—

|

—

|

—

|

—

|

|

|

AS

|

Intermediate shaft speed (+)

|

ISS sensor

|

Inspect resistance between TCM terminals AM and AS (wiring harness-side).

|

325—485 ohm

|

• Inspect the ISS sensor

• Inspect the related wiring harness

|

|

|

AT

|

—

|

—

|

—

|

—

|

—

|

|

|

AU

|

—

|

—

|

—

|

—

|

—

|

|

|

AV

|

—

|

—

|

—

|

—

|

—

|

|

|

AW

|

—

|

—

|

—

|

—

|

—

|

|

|

AX

|

TR3A signal

|

Digital TR sensor

|

Inspect continuity between TCM terminals AX and BH (wiring harness-side).

|

P position, 1,2 and 3 range

|

Continuity

|

• Inspect the Digital TR sensor

• Inspect the related wiring harness

|

|

Other

|

Not continuity

|

|||||

|

AY

|

ATF temperature

|

TFT sensor

|

Inspect resistance between TCM terminals AY and BH (wiring harness-side).

|

ATF temperature

-40—-20 °C

{-40—-4 °F}

|

284—967 kilohm

|

• Inspect the TFT sensor

• Inspect the related wiring harness

|

|

ATF temperature

-19—-1 °C

{-3—30 °F}

|

100—284 kilohm

|

|||||

|

ATF temperature

0—20 °C

{32—68 °F}

|

37—100 kilohm

|

|||||

|

ATF temperature

21—40 °C

{70—104 °F}

|

16—37 kilohm

|

|||||

|

ATF temperature

41—70 °C

{106—158 °F}

|

5—16 kilohm

|

|||||

|

ATF temperature

71—90 °C

{160—194 °F}

|

2.7—5 kilohm

|

|||||

|

ATF temperature

91—110 °C

{196—230 °F}

|

1.5—2.7 kilohm

|

|||||

|

ATF temperature

111—130 °C

{232—266 °F}

|

0.8—1.5 kilohm

|

|||||

|

ATF temperature

131—150 °C

{268—302 °F}

|

0.54—0.8 kilohm

|

|||||

|

AZ

|

—

|

—

|

—

|

—

|

—

|

|

|

BA

|

4x4 HI mode input

|

4x4 control module

|

Inspect continuity between TCM and 4x4 control module (wiring harness-side).

|

Continuity

|

• Inspect the 4x4 control module

• Inspect the related wiring harness

|

|

|

BB

|

4x4 LO mode input

|

4x4 control module

|

Inspect continuity between TCM and 4x4 control module (wiring harness-side).

|

Continuity

|

• Inspect the 4x4 control module

• Inspect the related wiring harness

|

|

|

BC

|

—

|

—

|

—

|

—

|

—

|

|

|

BD

|

—

|

—

|

—

|

—

|

—

|

|

|

BE

|

—

|

—

|

—

|

—

|

—

|

|

|

BF

|

—

|

—

|

—

|

—

|

—

|

|

|

BG

|

—

|

—

|

—

|

—

|

—

|

|

|

BH

|

Sensor GND

|

• TFT sensor

• Digital TR sensor

|

Inspect the TCM terminals AX, AY, BU, BY and CA.(wiring harness-side)

|

• Inspect the related wiring harness

|

||

|

BI

|

—

|

—

|

—

|

—

|

—

|

|

|

BJ

|

—

|

—

|

—

|

—

|

—

|

|

|

BK

|

—

|

—

|

—

|

—

|

—

|

|

|

BL

|

—

|

—

|

—

|

—

|

—

|

|

|

BM

|

O/D OFF switch

|

O/D OFF switch

|

Engine switch ON

|

O/D OFF switch button depressed

|

B+

|

• Inspect the O/D OFF switch

• Inspect the related wiring harness

|

|

O/D OFF switch button not depressed

|

Below 1.0 V

|

|||||

|

BN

|

—

|

—

|

—

|

—

|

—

|

|

|

BO

|

—

|

—

|

—

|

—

|

—

|

|

|

BP

|

—

|

—

|

—

|

—

|

—

|

|

|

BQ

|

—

|

—

|

—

|

—

|

—

|

|

|

BR

|

—

|

—

|

—

|

—

|

—

|

|

|

BS

|

System GND

|

GND

|

Under any condition

|

Continuity

|

• Inspect the related wiring harness

|

|

|

BT

|

—

|

—

|

—

|

—

|

—

|

|

|

BU

|

TR2 signal

|

Digital TR sensor

|

Inspect continuity between TCM terminals BU and BH (wiring harness-side).

|

P, R position and 2 range

|

Continuity

|

• Inspect the Digital TR sensor

• Inspect the related wiring harness

|

|

Other

|

Not continuity

|

|||||

|

BV

|

—

|

—

|

—

|

—

|

—

|

|

|

BW

|

—

|

—

|

—

|

—

|

—

|

|

|

BX

|

—

|

—

|

—

|

—

|

—

|

|

|

BY

|

TR1 signal

|

Digital TR sensor

|

Inspect continuity between TCM terminals BY and BH (wiring harness-side).

|

P, R position and 3 range

|

Continuity

|

• Inspect the Digital TR sensor

• Inspect the related wiring harness

|

|

Other

|

Not continuity

|

|||||

|

BZ

|

—

|

—

|

—

|

|

—

|

—

|

|

CA

|

TR4 signal

|

Digital TR sensor

|

Inspect continuity between TCM terminals CA and BH (wiring harness-side).

|

P, N position and 1 range

|

Continuity

|

• Inspect the Digital TR sensor

• Inspect the related wiring harness

|

|

Other

|

Not continuity

|

|||||

|

CB

|

CAN_H

|

PCM

|

Because this terminal is for serial communication, good/no good judgment by terminal voltage is not possible. Carry out inspection according to DTCs.

|

—

|

• Inspect the related wiring harness

|

|

|

CC

|

—

|

—

|

—

|

—

|

—

|

|

|

CD

|

—

|

—

|

—

|

—

|

—

|

|

|

CE

|

—

|

—

|

—

|

—

|

—

|

|

|

CF

|

CAN_L

|

PCM

|

Because this terminal is for serial communication, good/no good judgment by terminal voltage is not possible. Carry out inspection according to DTCs.

|

—

|

• Inspect the related wiring harness

|

|

|

CG

|

—

|

—

|

—

|

—

|

—

|

|

|

CH

|

—

|

—

|

—

|

—

|

—

|

|

|

CI

|

—

|

—

|

—

|

—

|

—

|

|

|

CJ

|

—

|

—

|

—

|

—

|

—

|

|

|

CK

|

Solenoid valve power supply

|

Solenoid valve

|

Inspect the TCM terminals A, B, C, D, F, I, J and M. (wiring harness-side)

|

• Inspect the solenoid valve

• Inspect the related wiring harness

|

||

|

CL

|

System GND

|

GND

|

Under any condition

|

Continuity

|

• Inspect the related wiring harness

|

|

|

CM

|

IG

|

AT relay

|

Engine switch ON

|

B+

|

• Inspect the AT relay

• Inspect the related wiring harness

|

|

|

Engine switch OFF

|

Below 1.0 V

|

|||||

|

CN

|

—

|

—

|

—

|

—

|

—

|

|

|

CO

|

System GND

|

GND

|

Under any condition

|

Continuity

|

• Inspect the related wiring harness

|

|

|

CP

|

IG

|

AT relay

|

Engine switch ON

|

B+

|

• Inspect the AT relay

• Inspect the related wiring harness

|

|

|

Engine switch OFF

|

Below 1.0 V

|

|||||