|

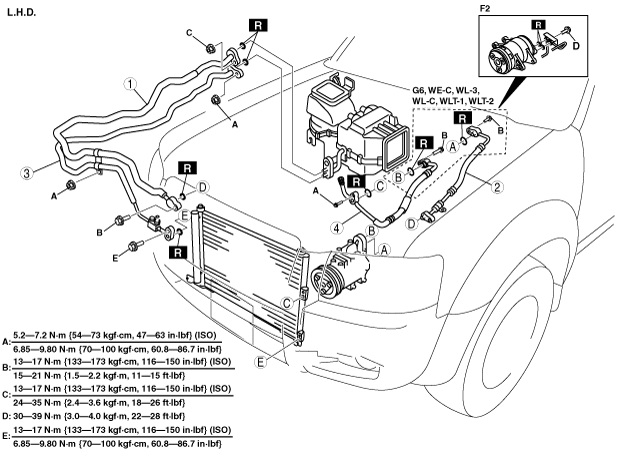

REFRIGERANT LINE REMOVAL/INSTALLATION

id071100801100

1. Disconnect the negative battery cable.

2. Discharge the refrigerant from the system. (See REFRIGERANT RECOVERY.) (See REFRIGERANT CHARGING.)

3. Remove the radiator grille. (See RADIATOR GRILLE REMOVAL/INSTALLATION.)

4. Remove the front bumper. (See FRONT BUMPER REMOVAL/INSTALLATION.)

5. Remove the radiator. (WLT-1, WLT-2 only)

6. Remove in the order indicated in the table. Do not allow compressor oil to spill.

absggw00002368

|

|

1

|

Cooler pipe (LO)

|

|

2

|

Cooler hose (LO)

(See Cooler Hose Removal Note.)

|

|

3

|

Cooler pipe (HI)

|

|

4

|

Cooler hose (HI)

(See Cooler Hose Removal Note.)

|

absggw00002369

|

|

1

|

Cooler hose (LO)

(See Cooler Hose Removal Note.)

|

|

2

|

Cooler hose (HI)

(See Cooler Hose Removal Note.)

|

|

3

|

Cooler pipe

|

7. Install in the reverse order of removal.

8. Perform the refrigerant system performance test. (See REFRIGERANT SYSTEM PERFORMANCE TEST.)

Cooler Hose Removal Note

WLT-1, WLT-2 only

Refrigerant Line Removal Note

Refrigerant Line Installation Note

1. When installing a new cooler pipe or hose, add FD46XG (G6, WE-C, WL-C, WLT-1, WLT-2) or ZXL 100PG (F2) compressor oil into the refrigeration cycle.

2. Apply compressor oil to the O-rings and connect the joints.

3. Tighten the joints.