|

absggw00000037

DRIVE BELT INSPECTION [G6]

id011095801500

Drive Belt Deflection Inspection

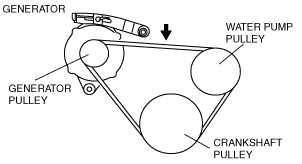

1. Verify the drive belt deflection when the engine is cold, or at least 30 min after the engine has been stopped. Apply pressure 98 N {10 kgf, 22lbf} midway between the specified pulleys.

absggw00000037

|

absggw00000038

|

absggw00000039

|

Drive belt deflection

|

Drive Belt |

*New |

Used |

|---|---|---|

|

Generator

|

10.0—12.0 mm {0.40—0.47 in}

|

12.0—14.0 mm {0.48—0.55 in}

|

|

P/S

|

6.6—7.2 mm {0.26—0.28 in}

|

7.2—8.0 mm {0.29—0.31 in}

|

|

A/C

|

8.5—10.0 mm {0.34—0.39 in}

|

10.0—11.5 mm {0.40—0.45 in}

|

Drive Belt Tension Inspection

1. Belt tension can be verified in place of belt deflection. verify the drive belt tension when the engine is cold, or at least 30 min after the engine has been stopped. Using the SST, verify the belt tension between any two pulleys.

absggw00000005

|

Drive belt tension

|

Drive Belt |

*New |

Used |

|---|---|---|

|

Generator

|

490—588 N{50—59 kgf, 111—132 lbf}

|

392—490 N {40—49 kgf, 89—110 lbf}

|

|

P/S

|

412—471 N {43—48 kgf, 93—105 lbf}

|

353—402 N {36—40 kgf, 80—90 lbf}

|

|

A/C

|

556—641 N {57—65 kgf, 125—144 lbf}

|

470—556 N {48—56 kgf, 106—124 lbf}

|