• If there are damaged fins, cracks or bends, replace the turbocharger. (See EXHAUST SYSTEM REMOVAL/INSTALLATION [WLT-1, WLT-2].)

-

Note

-

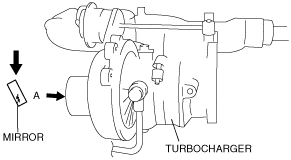

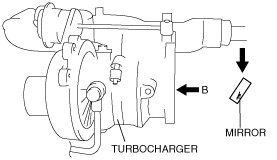

• To make the inspection easier, set a small mirror as shown in the figure and use a penlight.• If the compressor wheel is interfering with the compressor housing, it is likely that the fin edges are cracked, damaged, or bent.• If the compressor wheel is damaged, check the following before replacing the turbocharger to avoid reoccurrence of the malfunction.

-

― Foreign material in intake air/exhaust system.― Oil pipe clogging.

-

absggw00000560

|