|

PRESSURE REGULATOR INSPECTION [G6]

id011495800800

Simulation Test

1. Carry out the “Fuel Line Pressure Inspection”. (See ENGINE CONTROL SYSTEM OPERATION INSPECTION [G6].)

Operation Inspection

1. Complete the “BEFORE REPAIR PROCEDURE”. (See BEFORE REPAIR PROCEDURE [G6].)

2. Disconnect the negative battery cable.

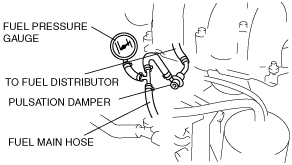

3. Connect a fuel pressure gauge between the pulsation damper and fuel main hose.

absggw00000192

|

4. Connect the negative battery cable.

5. Start the engine and let it idle.

6. Measure the fuel line pressure after approx. 2 min.

7. Disconnect the vacuum hose from the pressure regulator and measure the fuel line pressure.

absggw00000193

|

8. Turn the ignition switch off.

9. Complete the “BEFORE REPAIR PROCEDURE”. (See BEFORE REPAIR PROCEDURE [G6].)

10. Disconnect the negative battery cable.

11. Disconnect the fuel pressure gauge.

12. Reconnect the fuel main hose to the fuel distributor.

13. Reconnect the negative battery cable.

14. Complete the “AFTER REPAIR PROCEDURE”. (See AFTER REPAIR PROCEDURE [G6].)