|

absggw00000577

FUEL TANK INSPECTION [WLT-1, WLT-2]

id011496803200

1. Follow “BEFORE REPAIR PROCEDURE” before performing any work operations to prevent fuel from spilling from the fuel system. (See BEFORE REPAIR PROCEDURE [WLT-1, WLT-2].)

2. Disconnect the negative battery cable.

3. Remove the fuel tank. (See FUEL TANK REMOVAL/INSTALLATION [WLT-1, WLT-2].)

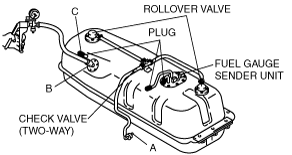

4. Plug the fuel pipe of the fuel gauge sender unit.

5. Plug port C.

6. Connect the pump to port B.

absggw00000577

|

7. Level the fuel tank.

8. Apply pressure of 5—6 kPa {38—45 mmHg, 1.5—1.7 inHg} to port B.

absggw00000578

|

9. Apply pressure of –5—–6 kPa {–38—–45 mmHg, –1.5—–1.7 inHg} to port B.

absggw00000578

|

absggw00000579

|

10. Apply pressure of 5—6 kPa {38—45 mmHg, 1.5—1.7 inHg} to port B.

absggw00000578

|