|

dbg140awb701

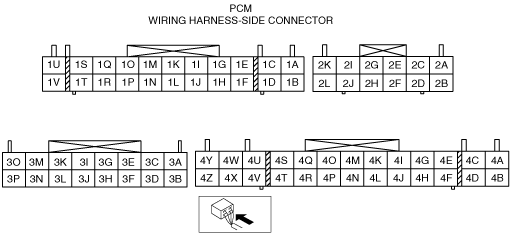

PCM INSPECTION [WL-3]

id0140b5802500

Without Using the M-MDS

dbg140awb701

|

Terminal voltage table (Reference)

|

Terminal |

Signal |

Connected to |

Test condition |

Voltage (V) |

Inspection item |

|

|---|---|---|---|---|---|---|

|

1A

|

Constant voltage

(Vref)

|

Injection pump EPROM, EGR valve position sensor, Boost sensor, APP sensor

|

Engine switch ON

|

Approx. 5

|

• Inspect related wiring harness

• Injection pump EPROM

• EGR valve position sensor

• Boost sensor

• APP sensor

|

|

|

1B

|

Ground

|

Body ground

|

Under any condition

|

Below 1.0

|

• Inspect related wiring harness

|

|

|

1C

|

Power supply

|

Power supply

|

Under any condition

|

B+

|

• Inspect related wiring harness

|

|

|

1D

|

Clutch

|

CPP switch

|

Clutch pedal depressed

|

Below 1.0

|

• Inspect related wiring harness

• CPP switch

|

|

|

Clutch pedal released

|

B+

|

|||||

|

1E

|

—

|

—

|

—

|

—

|

—

|

|

|

1F

|

EGR position

|

EGR valve

|

Engine switch ON

|

Below 1.0

|

• Inspect related wiring harness

• EGR valve

|

|

|

EGR valve operating

|

Approx. 3

|

|||||

|

1G

|

Ground

|

Timer position sensor

|

Under any condition

|

Below 1.0

|

• Inspect related wiring harness

|

|

|

1H

|

CKP

|

CKP sensor

|

Inspection using the wave Profile.

|

• Inspect related wiring harness

• CKP sensor

|

||

|

1I

|

Timer position

|

Timer position sensor

|

Engine switch ON

|

Approx. 2.5

|

|

|

|

1J

|

IAT

|

IAT sensor No.1

|

Engine switch ON

|

IAT 20 °C

{68 °F}

|

2.3—2.5

|

• Inspect related wiring harness

• IAT sensor No.1

|

|

IAT 30 °C

{86 °F}

|

1.8—2.0

|

|||||

|

1K

|

Constant voltage

|

Timer position sensor

|

Engine switch ON

|

Approx. 5

|

• Inspect related wiring harness

• Timer position sensor

|

|

|

1L

|

Fuel temp

|

Fuel temperature sensor

|

Engine switch ON

|

Fuel temperature

20 °C {68 °F}

|

2.4—2.6

|

• Inspect related wiring harness

• Fuel temperature sensor

|

|

Fuel temperature

70 °C {158 °F}

|

0.7—0.9

|

|||||

|

1M

|

Ground

|

Control sleeve position sensor

|

Under any condition

|

Below 1.0

|

• Inspect related wiring harness

• Control sleeve position sensor

|

|

|

1N

|

Vehicle speed

|

VSS

|

Inspection using the wave Profile.

|

• Inspect related wiring harness

• VSS

|

||

|

1O

|

Control sleeve position

|

Control sleeve position sensor

|

Engine switch ON

|

Approx. 2.5

|

• Inspect related wiring harness

• Control sleeve position sensor

|

|

|

1P

|

MAP

|

Boost sensor

|

Engine switch ON

|

Approx. 2.6

|

• Inspect related wiring harness

• Boost sensor

|

|

|

1Q

|

Constant voltage

|

Control sleeve position sensor

|

Engine switch ON

|

Approx. 2.5

|

• Inspect related wiring harness

• Control sleeve position sensor

|

|

|

1R

|

APP

|

APP sensor

|

Accelerator pedal released

|

0.5—0.7

|

• Inspect related wiring harness

• APP sensor

|

|

|

Accelerator pedal depressed

|

3.4—3.8

|

|||||

|

1S

|

Injection pump

|

Injection pump EPROM

|

Engine switch ON

|

Approx. 8.5

|

• Inspect related wiring harness

• Injection pump EPROM

|

|

|

Idle

|

Approx. 9.5

|

|||||

|

1T

|

ECT

|

ECT sensor

|

Engine switch ON

|

ECT 30 °C

{86 °F}

|

Approx. 2.6

|

• Inspect related wiring harness

• ECT sensor

|

|

ECT 50 °C

{122 °F}

|

Approx. 1.7

|

|||||

|

ECT 60 °C

{140 °F}

|

Approx. 1.4

|

|||||

|

ECT 80 °C

{176 °F}

|

Approx. 0.8

|

|||||

|

1U

|

Starter

|

Engine switch, Starter relay

|

Engine switch ON (START) position

|

B+

|

• Inspect related wiring harness

|

|

|

Except for engine switch ON (START) position

|

Below 1.0

|

|||||

|

1V

|

IG1

|

Engine switch

|

Engine switch ON and Start position

|

B+

|

• Inspect related wiring harness

|

|

|

Engine switch is other position

|

Below 1.0

|

|||||

|

2A

|

Diagnostic test mode

|

Data link connector (DLC) (Terminal TEN)

|

Engine switch ON

|

Open terminal TEN

|

B+

|

• Inspect related wiring harness

|

|

Short terminal TEN

|

Below 1.0

|

|||||

|

2B

|

Serial communication

|

Data link connector (DLC) (Terminal KLN)

|

Because this terminal is for serial communication, good/no good judgement by terminal voltage is not possible. Carry out inspection according to diagnostic trouble codes.

|

—

|

||

|

2C

|

APP

|

APP sensor

|

Accelerator pedal released

|

0.5—0.7

|

• Inspect related wiring harness

• APP sensor

|

|

|

Accelerator pedal depressed

|

3.4—3.8

|

|||||

|

2D

|

Injection pump

(Np–)

|

Injection pump

|

Inspection using the wave Profile.

|

• Inspect related wiring harness

• Injection pump

|

||

|

2E

|

Injection pump

|

Injection pump EPROM

|

Engine switch ON

|

Below 1.0

|

• Inspect related wiring harness

|

|

|

Idle

|

Approx. 4

|

|||||

|

2F

|

—

|

—

|

—

|

—

|

—

|

|

|

2G

|

—

|

—

|

—

|

—

|

—

|

|

|

2H

|

—

|

—

|

—

|

—

|

—

|

|

|

2I

|

—

|

—

|

—

|

—

|

—

|

|

|

2J

|

Tachometer

|

Tachometer

|

Engine switch ON

|

Below 1.0

|

• Inspect related wiring harness

• Tachometer

|

|

|

Idle

|

B+

|

|||||

|

2K

|

Injection pump

(Np+)

|

Injection pump

|

Inspection using the wave Profile.

|

• Inspect related wiring harness

• Injection pump

|

||

|

2L

|

Injection pump

|

Injection pump EPROM

|

Engine switch ON

|

Below 1.0

|

• Inspect related wiring harness

|

|

|

Idle

|

Approx. 4

|

|||||

|

3A

|

Main relay control

|

Main relay

|

Engine switch ON

|

Below 1.0

|

• Inspect related wiring harness

• Main relay

|

|

|

Engine switch OFF

|

B+

|

|||||

|

3B

|

—

|

—

|

—

|

—

|

—

|

|

|

3C

|

Cooling fan

|

Cooling fan switch

|

Engine switch ON

|

A/C operating

|

B+

|

• Inspect related wiring harness

|

|

A/C not operating

|

Approx. 0.87

|

|||||

|

3D

|

IAT

|

MAF sensor/IAT sensor No.2

|

Engine switch ON

|

IAT 20 °C

{68 °F}

|

2.3—2.5

|

• Inspect related wiring harness

• MAF sensor/IAT sensor No.2

|

|

IAT 30 °C

{86 °F}

|

1.8—2.0

|

|||||

|

3E

|

—

|

—

|

—

|

—

|

—

|

|

|

3F

|

—

|

—

|

—

|

—

|

—

|

|

|

3G

|

—

|

—

|

—

|

—

|

—

|

|

|

3H

|

—

|

—

|

—

|

—

|

—

|

|

|

3I

|

—

|

—

|

—

|

—

|

—

|

|

|

3J

|

—

|

—

|

—

|

—

|

—

|

|

|

3K

|

—

|

—

|

—

|

—

|

—

|

|

|

3L

|

—

|

—

|

—

|

—

|

—

|

|

|

3M

|

—

|

—

|

—

|

—

|

—

|

|

|

3N

|

—

|

—

|

—

|

—

|

—

|

|

|

3O

|

Idle switch

|

Idle switch

|

Accelerator pedal released

|

Below 1.0

|

• Inspect related wiring harness

• Idle switch

|

|

|

Accelerator pedal depressed

|

B+

|

|||||

|

3P

|

—

|

—

|

—

|

—

|

—

|

|

|

4A

|

Ground

|

Body ground

|

Under any condition

|

Below 1.0

|

• Inspect related wiring harness

|

|

|

4B

|

Ground

|

Body ground

|

Under any condition

|

Below 1.0

|

• Inspect related wiring harness

|

|

|

4C

|

B+

|

Main relay

|

Main relay ON

|

B+

|

• Inspect related wiring harness

• Main relay

|

|

|

Main relay OFF

|

Below 1.0

|

|||||

|

4D

|

B+

|

Main relay

|

Main relay ON

|

B+

|

• Inspect related wiring harness

• Main relay

|

|

|

Main relay OFF

|

Below 1.0

|

|||||

|

4E

|

MAF

|

MAF sensor/IAT sensor No.2

|

Engine switch ON

|

Below 1.0

|

• Inspect related wiring harness

• MAF sensor/IAT sensor No.2

|

|

|

Idle

|

1.6—2.0

|

|||||

|

4F

|

—

|

—

|

—

|

—

|

—

|

|

|

4G

|

—

|

—

|

—

|

—

|

—

|

|

|

4H

|

—

|

—

|

—

|

—

|

—

|

|

|

4I

|

EGR control solenoid valve

|

EGR control solenoid valve

|

Engine speed is 3,000 rpm

|

B+

|

• Inspect related wiring harness

• EGR control solenoid valve

|

|

|

Idle

|

Below 1.0

|

|||||

|

4J

|

—

|

—

|

—

|

—

|

—

|

|

|

4K

|

DTC output

|

Data link connector (DLC) (Terminal FEN)

|

No DTC output

|

Below 1.0

|

• Inspect related wiring harness

|

|

|

DTC output

|

0—B+

|

|||||

|

4L

|

A/C

|

A/C relay

|

A/C operating

|

Below 1.0

|

• Inspect related wiring harness

• A/C relay

|

|

|

A/C not operating

|

B+

|

|||||

|

4M

|

—

|

—

|

—

|

—

|

—

|

|

|

4N

|

—

|

—

|

—

|

—

|

—

|

|

|

4O

|

—

|

—

|

—

|

—

|

—

|

|

|

4P

|

—

|

—

|

—

|

—

|

—

|

|

|

4Q

|

EGRA

|

EGR solenoid valve

(Vent)

|

Engine switch ON

|

B+

|

• Inspect related wiring harness

• EGR solenoid valve (Vent)

|

|

|

Idle

|

Below 1.0

|

|||||

|

4R

|

—

|

—

|

—

|

—

|

—

|

|

|

4S

|

Glow indicator light

|

Glow indicator light

|

Engine switch OFF

|

Below 1.0

|

• Inspect related wiring harness

• Glow indicator light

|

|

|

Engine switch is ON and within approx. 4.5 sec. (25 °C {77 °F})

|

||||||

|

Over 4.5 seconds (25 °C {77 °F}) after turning engine switch ON.

|

B+

|

|||||

|

4T

|

EGRV

|

EGR solenoid valve

(Vacuum)

|

Engine switch ON

|

B+

|

• Inspect related wiring harness

• EGR solenoid valve (Vacuum)

|

|

|

4U

|

TCV

|

Timer control valve

|

Engine switch ON

|

B+

|

• Inspect related wiring harness

• Timer control valve

|

|

|

Idle

|

Below 1.0

|

|||||

|

4V

|

Glow system

|

Glow relay

|

ECT is below 60 °C {140 °F}

|

For less than approx. 15 seconds after turning engine switch ON.

|

B+

|

• Inspect related wiring harness

• Glow relay

|

|

Over approx. 15 seconds after turning engine switch ON.

|

Below 1.0

|

|||||

|

For less than 10 minutes starting engine.

|

B+

|

|||||

|

Over 10 minutes after starting engine.

|

Below 1.0

|

|||||

|

While cranking

|

B+

|

|||||

|

ECT is above 60 °C {140 °F}

|

For less than approx. 2 seconds after turning engine switch ON.

|

B+

|

||||

|

Over approx. 2 seconds after turning engine switch ON.

|

Below 1.0

|

|||||

|

While cranking

|

B+

|

|||||

|

4W

|

FCV

|

Fuel cut solenoid valve

|

Engine switch ON

|

Below 1.0

|

• Inspect related wiring harness

• Fuel cut solenoid valve

|

|

|

Idle

|

B+

|

|||||

|

4X

|

Electronic governor voltage

|

Electronic governor

|

Engine switch ON

|

B+

|

• Inspect related wiring harness

|

|

|

4Y

|

Electronic governor

|

Electronic governor

|

Engine switch ON

|

B+

|

• Inspect related wiring harness

|

|

|

4Z

|

—

|

—

|

—

|

—

|

—

|

|

Inspection Using An Oscilloscope (Reference)

CKP signal

dbg140awb104

|

Vehicle speed signal

dbg140awb184

|

Injection pump (speed sensor) signal

dbg140awb102

|

Electronic governor signal

dbg140awb103

|

Using M-MDS

1. Connect the M-MDS to the DLC-2. (See ON-BOARD DIAGNOSTIC TEST [WL-3].)

2. Measure the PID value.

3. Turn the engine switch to the ON position (Engine off).

PID Monitor Table (Reference)

|

Monitor item (Definition) |

Unit/Condition |

Condition/Specification |

Action |

PCM terminal |

|||||

|---|---|---|---|---|---|---|---|---|---|

|

ACCS (Air conditioning compressor cycling switch)

|

ON/OFF

|

Engine switch is ON: OFF

A/C switch is ON at idle: ON

|

Inspect following PIDs: TP, ECT, ACSW, CPP/PNP, VSS, STARTER.

Inspect A/C relay.

|

4L

|

|||||

|

ACSW (A/C switch)

|

ON/OFF

|

A/C switch is ON with engine switch ON: ON

A/C switch is OFF with engine switch ON: OFF

|

Inspect refrigerant pressure switch.

|

3C

|

|||||

|

ARPMDES (Target engine speed)

|

rpm

|

A/C ON: 750 rpm

Other: 720 rpm

|

Inspect A/C switch.

|

—

|

|||||

|

BARO (Barometric pressure)

|

kPa

|

Bar

|

psi

|

Elevation 0—400 m {0—1310 ft}: 100—103 kPa {1.00—1.03 Bar, 14.5—14.9 psi}

|

Replace PCM.

|

—

|

|||

|

V

|

Elevation 0—400 m {0—1310 ft}: approx. 4.0 V

|

||||||||

|

CPP/PNP (Neutral/clutch pedal position)

|

ON/OFF

|

Neutral position or clutch pedal is depressed: ON

Others: OFF

|

Inspect neutral switch and CPP switch.

|

1D

|

|||||

|

CSP (Control sleeve signal voltage)

|

V

|

Engine switch is wiring harness: below 1.0 V

Engine switch is ON or idle: approx. 2.5 V

|

Inspect control sleeve (CS) sensor.

|

1Q

|

|||||

|

ECT (Engine coolant temperature)

|

°C

|

°F

|

ECT is 20°C {68°F}: 20°C {68°F}

ECT is 85°C {185°F}: 85°C {185°F}

|

Inspect ECT sensor.

|

1T

|

||||

|

V

|

ECT is 20°C {68°F}: 3.0—3.2 V

ECT is 85°C {185°F}: 0.7—0.9 V

|

||||||||

|

EGRA (EGR solenoid valve (vent))

|

%

|

Engine switch is ON: 0—100%

Idle: 0—100%

|

Inspect following PIDs: ECT, TP, IDLE SW, MAF, IAT, RPM, EGRVP.

Inspect EGR solenoid valve (vent).

|

4Q

|

|||||

|

EGRV (EGR solenoid valve (vacuum))

|

%

|

Engine switch is ON: 0—100%

Idle: 0—100%

|

Inspect following PIDs: ECT, TP, IDLE SW, MAF, IAT, RPM, EGRVP.

Inspect EGR solenoid valve (vent).

|

4T

|

|||||

|

EGRVP (EGR valve position)

|

V

|

Engine switch is ON: Below 1.0

Idle: above 3.0 V

|

Inspect EGR valve position sensor.

|

1F

|

|||||

|

FLT (Fuel temperature sensor)

|

°C

|

°F

|

Fuel temperature is 20°C {68°F}: 20°C {68°F}:

|

Inspect fuel temperature sensor.

|

1L

|

||||

|

FLT V (Fuel temperature signal voltage)

|

V

|

Fuel temperature is 20°C {68°F}: 2.4—2.6 V

Fuel temperature is 70°C {158°F}: 0.7—0.9 V

|

Inspect fuel temperature sensor.

|

1L

|

|||||

|

FSOV (Fuel cut solenoid valve)

|

ON/OFF

|

Idle: ON

Engine switch is ON: ON

Engine speed is above 5,100 rpm: OFF

DTC P1182, P0251, P0606, P1226 is detected: OFF

|

Perform applicable DTC troubleshooting

|

4W

|

|||||

|

GPC (Glow plug relay)

|

ON/OFF

|

ECT below 60°C {140°F}

• For 15 s after engine switch ON: ON

• After 15 s elapse from engine switch ON: OFF

• For 6.5 s—10 min after engine started: ON

• After 6.5 s—10 min elapse from engine started: OFF

ECT above 60°C {140°F}

• For 6.5 s after engine switch ON: ON

• After 6.5 s elapse from engine switch ON: OFF

|

Inspect following PIDs: ECT, VSS, VPWR.

Inspect glow plug relay.

|

4V

|

|||||

|

GP_LMP

(Glow indicator light)

|

ON/OFF

|

For 4s after engine switch ON (ECT is 20°C {68°F}): ON

|

Inspect instrument cluster.

|

4S

|

|||||

|

IAT (Intake air temperature (IAT sensor No.1))

|

°C

|

°F

|

IAT is 20°C {68°F}: 20°C {68°F}

IAT is 30°C {86°F}: 30°C {86°F}

|

Inspect IAT sensor No.1.

|

1J

|

||||

|

V

|

IAT is 20°C {68°F}: 2.3—2.5 V

IAT is 30°C {86°F}: 1.8—2.0 V

|

||||||||

|

IAT2 (Intake air temperature (IAT sensor No.2))

|

°C

|

°F

|

IAT is 20°C {68°F}: 20°C {68°F}

IAT is 30°C {86°F}: 30°C {86°F}

|

Inspect MAF sensor/IAT sensor No.2.

|

3D

|

||||

|

V

|

IAT is 20°C {68°F}: 2.3—2.5 V

IAT is 30°C {86°F}: 1.8—2.0 V

|

||||||||

|

IDLE SW (Idle switch)

|

ON/OFF

|

Accelerator pedal is released: ON

Other: OFF

|

Inspect idle switch.

|

3O

|

|||||

|

MAF (mass airflow amount)

|

V

|

Engine switch is ON: below 1.0 V

Idle: 1.6—2.0 V

|

Inspect MAF sensor/IAT sensor No.2.

|

4E

|

|||||

|

MAINRLY (Main relay)

|

ON/OFF

|

Engine switch is ON: ON

Other: OFF

|

Inspect engine switch.

|

3A

|

|||||

|

MAP (Boost sensor)

|

kPa

|

Bar

|

psi

|

Idle: 101kPa {1.01 Bar, 14.7psi}

|

Inspect boost sensor.

|

1P

|

|||

|

V

|

Idle: approx. 2.6V

|

||||||||

|

MIL (Malfunction indicator lamp)

|

ON/OFF

|

Engine switch is ON: ON

Idle: OFF

|

Perform applicable DTC troubleshooting

|

—

|

|||||

|

RPM (Engine speed)

|

rpm

|

A/C ON: 725—775rpm

Other: 695—745rpm

|

Inspect following PIDs: TP, MAP, RPM

|

1H

|

|||||

|

SELTESTDTC (Diagnostic trouble codes)

|

—

|

—

|

Perform applicable DTC troubleshooting

|

—

|

|||||

|

STARTER (Engine switch)

|

ON/OFF

|

Engine switch at START: ON

Other: OFF

|

Inspect engine switch.

|

1U

|

|||||

|

TCV (Timer control valve signal)

|

%

|

Idle: 99.6 %

Engine speed 2,000 rpm: 35 %

|

Inspect timer control valve

|

4U

|

|||||

|

TPS (Timer position sensor signal)

|

%

|

Engine switch is ON: 0%

Idle: 100%

|

Inspect timer position sensor.

|

1K

|

|||||

|

TEST (TEN terminal (in DLC))

|

ON/OFF

|

Terminal TEN (DLC) is shorted to ground: ON

Terminal TEN (DLC) is open: OFF

|

Inspect wiring from DLC terminal TEN to PCM terminal 2A.

|

2A

|

|||||

|

TP (Accelerator pedal position sensor No.1)

|

V

|

Accelerator pedal is depressed: 3.4—3.8 V

Accelerator pedal is released:0.5—0.7 V

|

Inspect accelerator pedal position sensor.

|

1R

|

|||||

|

TP2 V (Accelerator pedal position sensor No.2)

|

V

|

Accelerator pedal is depressed: 3.4—3.8 V

Accelerator pedal is released: 0.5—0.7 V

|

Inspect accelerator pedal position sensor.

|

2C

|

|||||

|

VPWR (Battery positive voltage)

|

V

|

Engine switch is ON: B+

Other: below 1.0 V

|

Inspect main relay.

|

4C

|

|||||

|

VSS (Vehicle speed)

|

km/h

|

mph

|

Vehicle speed is 20 km/h {12.5 mph}: 20 km/h {12.5 mph}

Vehicle speed is 40 km/h {25 mph}: 40 km/h {25 mph}

|

Inspect Instrument cluster.

|

1N

|

||||