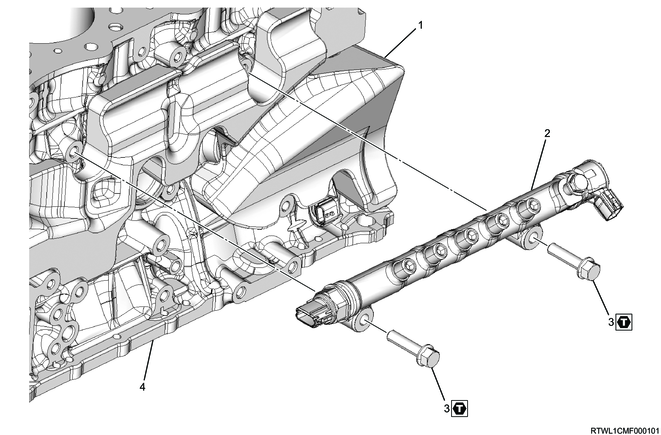

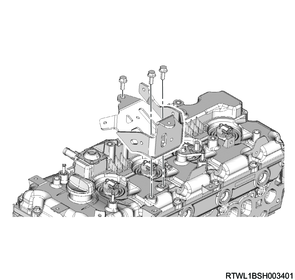

1. Component views

Common rail (fuel rail)

Part name

- Cylinder block cover

- Common rail (fuel rail)

- Bolt

- Cylinder block

Tightening torque

3: 51 N・m { 5.2 kgf・m / 38 lb・ft }

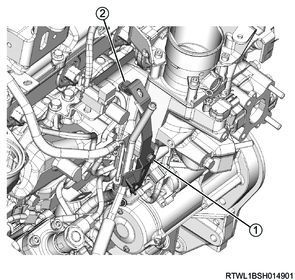

2. Common rail (fuel rail) installation

1) Install the common rail (fuel rail) to the cylinder block.

Tightening torque: 51 N・m { 5.2 kgf・m / 38 lb・ft }

Caution

- Do not hold the FRP sensor or pressure-reducing valve.

- Do not damage the FRP sensor or pressure-reducing valve.

Legend

- FRP sensor

- Common rail (fuel rail)

- Pressure-reducing valve

2) Connect the connector to the FRP sensor.

3) Connect the connector to the pressure-reducing valve.

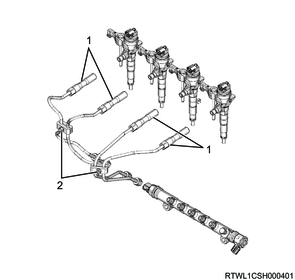

3. Injection pipe installation

1) Apply engine oil to the threaded portions of the sleeve nuts on the injector side, as well as the injector O-rings.

2) Temporarily tighten the injection pipes to the common rail (fuel rail) and injectors by hand until the sleeve nuts can no longer turn.

Caution

- Do not reuse the injection pipe.

Legend

- Injection pipe

- Clip

3) Temporarily tighten the clip to the injection pipe.

4) Final tighten the injector clamp bolt to the cylinder head.

Tightening torque: 26 N・m { 2.7 kgf・m / 19 lb・ft }

5) Final tighten the injection pipes to the injectors and common rail (fuel rail).

Tightening torque: 44 N・m { 4.5 kgf・m / 32 lb・ft } Injector side

Tightening torque: 44 N・m { 4.5 kgf・m / 32 lb・ft } Common rail (fuel rail) side

6) Securely tighten the clip to the injection pipe.

Tightening torque: 8.0 N・m { 0.8 kgf・m / 71 lb・in }

4. Fuel feed pipe installation

1) Install the fuel feed pipe to the fuel supply pump and common rail (fuel rail).

Caution

- Do not reuse the fuel feed pipe.

Tightening torque: 44 N・m { 4.5 kgf・m / 32 lb・ft }

Legend

- Fuel supply pump

- Fuel feed pipe

- Common rail (fuel rail)

5. Fuel leak-off pipe installation

1) Install the fuel leak-off pipe to the fuel supply pump and common rail (fuel rail).

Tightening torque: 10.3 N・m { 1.1 kgf・m / 91 lb・in } Fuel supply pump side

Tightening torque: 25 N・m { 2.5 kgf・m / 18 lb・ft } Cylinder block side

Tightening torque: 10.3 N・m { 1.1 kgf・m / 91 lb・in } Common rail (fuel rail) side

Legend

- Leak-off hose

- Fuel leak-off pipe

6. EGR cooler bypass control solenoid valve installation

1) Install the EGR cooler bypass control solenoid valve and bracket as a set to the inlet manifold.

Tightening torque: 25 N・m { 2.5 kgf・m / 18 lb・ft }

2) Connect the vacuum hose to the EGR cooler bypass control solenoid valve.

3) Connect the connector to the EGR cooler bypass control solenoid valve.

Legend

- EGR cooler bypass control solenoid valve

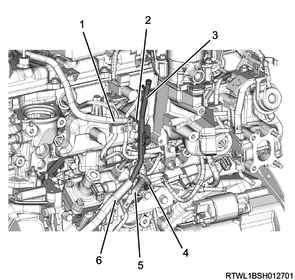

7. Leak-off pipe installation

1) Install the leak-off pipe to the inlet manifold.

Tightening torque: 25 N・m { 2.5 kgf・m / 18 lb・ft }

2) Connect the 2 leak-off hoses to the leak-off pipe.

3) Connect the 3 vacuum hoses to the vacuum pipe.

Legend

- Leak-off hose (Injector side)

- Leak-off pipe

- Vacuum pipe

- Vacuum hose (EGR cooler bypass control solenoid valve side)

- Leak-off hose (Supply pump side)

- Vacuum hose (Vacuum pump side)

4) Temporarily tighten the harness brackets to the inlet manifold in the order shown in the diagram.

5) Final tighten the harness brackets to the inlet manifold in the order shown in the diagram.

Tightening torque: 10.0 N・m { 1.0 kgf・m / 89 lb・in }

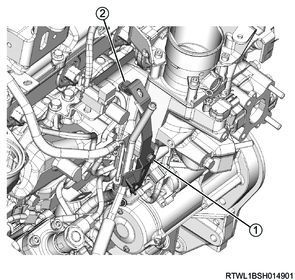

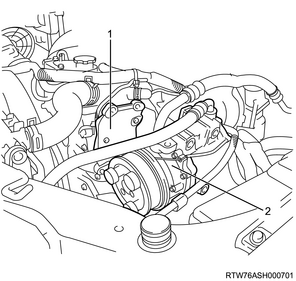

8. A/C compressor connect

1) Connect the A/C compressor to the A/C compressor bracket.

Tightening torque: 51 N・m { 5.2 kgf・m / 38 lb・ft }

Legend

- A/C compressor bracket

- A/C compressor

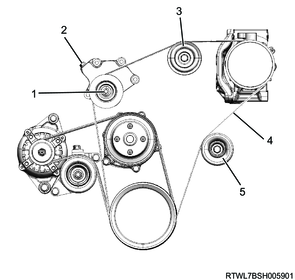

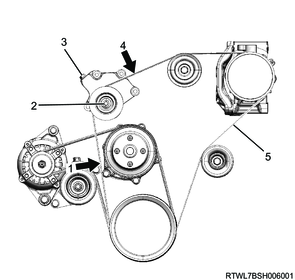

9. A/C compressor drive belt installation

1) Install the A/C compressor drive belt to the following parts.

- Tension pulley

- A/C compressor

- Crankshaft pulley

- Idle pulley

Legend

- Lock nut

- Adjust bolt

- Idle pulley

- A/C compressor drive belt

- Idle pulley

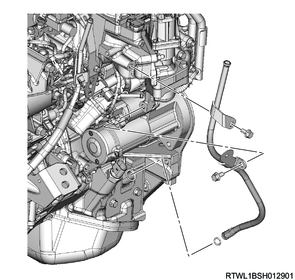

10. Oil level gauge guide tube installation

1) Apply engine oil to the O-ring.

2) Install the oil level gauge guide tube to the crankcase.

Tightening torque: 25 N・m { 2.5 kgf・m / 18 lb・ft }

3) Install the oil level gauge to the oil level gauge guide tube.

11. Air duct bracket installation

1) Install the air duct bracket to the cylinder head cover.

Tightening torque: 25 N・m { 2.5 kgf・m / 18 lb・ft }

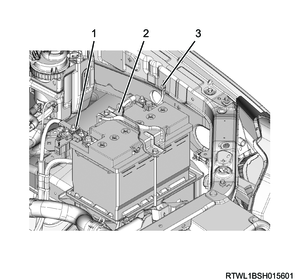

12. Battery installation

1) Install the battery to vehicle.

2) Install the battery bracket to the frame.

Tightening torque: 4.0 N・m { 0.41 kgf・m / 35.4 lb・in } Battery side

Tightening torque: 20 N・m { 2.0 kgf・m / 15 lb・ft } Frame side

3) Connect the battery cable to the battery.

4) Connect the battery ground cable to the frame.

Legend

- Battery cable

- Battery bracket

- Battery ground cable

13. Intake throttle valve installation

14. A/C compressor drive belt adjustment

When installing a new belt, initial stretching of the belt occurs.

In addition, when reusing the belt, the belt needs to be fitted to the pulley groove.

After fitting the A/C compressor drive belt, adjust the tension of the A/C compressor drive belt again.

1) Loosen the tension pulley lock nut.

2) Turn the tension pulley adjust bolt to adjust the tension.

Note

- The standard deflection shown is the value obtained when the specified load is applied to the measurement point of the A/C compressor drive belt.

98 N { 10.0 kg / 22 lb } Load

Caution

- Accurately adjust the tension as there is a possibility the service life of the belt may be shortened or belt squeal may be generated if the tension is not within the appropriate range.

- Use a sonic tension meter to verify accurate tension adjustment.

| Adjustment conditions |

Deflection |

Vibration frequency |

| When new |

10.2 to 11.2 mm { 0.40 to 0.44 in } |

163 to 179 Hz |

| Reused |

12.1 to 13.3 mm { 0.48 to 0.52 in } |

131 to 147 Hz |

| Adjustment conditions |

Deflection |

Vibration frequency |

| When new |

6.8 to 7.4 mm { 0.27 to 0.29 in } |

249 to 273 Hz |

| Reused |

7.9 to 8.7 mm { 0.31 to 0.34 in } |

201 to 225 Hz |

Legend

- Measurement point 1

- Lock nut

- Adjust bolt

- Measurement point 4

- A/C compressor drive belt

3) Tighten the tension pulley lock nut to the specified torque.

Tightening torque: 51 N・m { 5.2 kgf・m / 38 lb・ft }