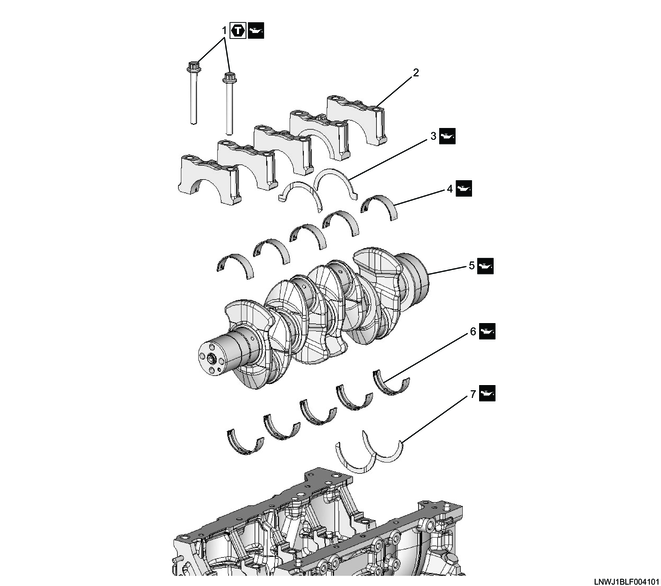

1. Component views

Crankshaft

Part name

- Bolt

- Bearing cap

- Thrust bearing

- Lower crankshaft bearing

- Crankshaft

- Upper crankshaft bearing

- Thrust bearing

Tightening torque

1-1: 50 N・m { 5.1 kgf・m / 36.9 lb・ft }

1-2: 60 to 90 °

2. Crankshaft installation

If replacing the crankshaft bearing, select the crankshaft bearing grade.

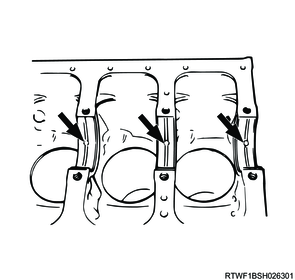

1) Check the cylinder block journal hole inner diameter grade.

Note

- Grade 1, 2, or 3 is marked on the bottom surface of the cylinder block.

Legend

- No. 1

- No. 2

- No. 3

- No. 4

- No. 5

| Marking |

Journal diameter |

| 1 |

61.992 to 62.000 mm { 2.4406 to 2.4409 in } |

| 2 |

61.984 to 61.991 mm { 2.4403 to 2.4406 in } |

| 3 |

61.976 to 61.983 mm { 2.4400 to 2.4403 in } |

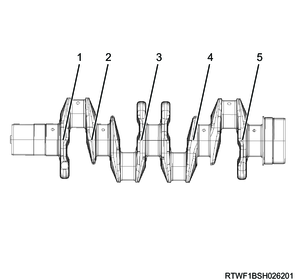

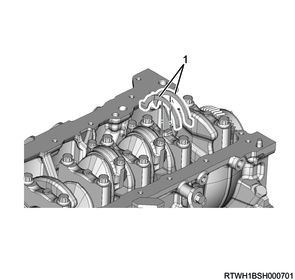

2) Check the crankshaft journal diameter grade.

Note

- The crankshaft journal grade marking is marked on each crankshaft journal.

Legend

- No. 1

- No. 2

- No. 3

- No. 4

- No. 5

| Marking |

Journal diameter |

|

| Other than the No. 3 journal |

No. 3 journal |

|

| 1 |

57.933 to 57.938 mm { 2.2808 to 2.2810 in } |

57.919 to 57.924 mm { 2.2803 to 2.2805 in } |

| 2 |

57.928 to 57.933 mm { 2.2806 to 2.2808 in } |

57.914 to 57.919 mm { 2.2801 to 2.2803 in } |

| 3 |

57.923 to 57.928 mm { 2.2804 to 2.2806 in } |

57.909 to 57.914 mm { 2.2799 to 2.2801 in } |

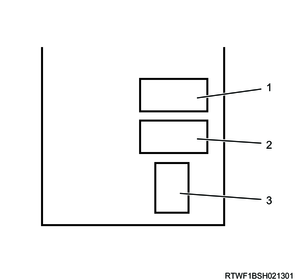

3) Inspect the crankshaft bearing for the following.

- Size

- Lot number

- Code

Legend

- Size

- Lot No.

- Code

4) Select the crankshaft bearing based on the journal hole inner diameter grades of the crankshaft journal and cylinder block.

| Crankshaft journal grade |

||||

| 1 |

2 |

3 |

||

| Cylinder block journal grade |

1 |

Code: 3 |

Code: 3 |

Code: 4 |

| 2 |

Code: 2 |

Code: 2 |

Code: 3 |

|

| 3 |

Code: 1 |

Code: 1 |

Code: 2 |

|

5) Install the crankshaft upper bearing to the cylinder block.

Note

- Check that the crankshaft upper bearing has oil holes and an oil groove.

Caution

- Do not confuse the difference of bearing shapes.

6) Apply engine oil to the crankshaft upper bearing surface.

Caution

- Do not apply engine oil to the cylinder block installation surface and back surface of the bearing.

7) Thoroughly apply engine oil to the crankshaft journal section.

8) Install the crankshaft to the cylinder block.

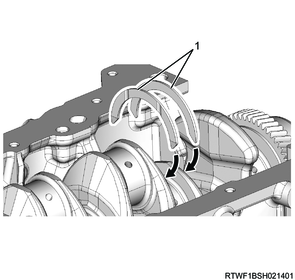

9) Thoroughly apply engine oil to the thrust bearing.

10) Install the thrust bearings to the front and rear sides of the cylinder block No. 4 journal.

Caution

- Install so that the oil groove of the thrust bearing touches the crankshaft.

Legend

- Thrust bearing

11) Install the lower crankshaft bearing to the bearing cap.

12) Apply engine oil to the lower crankshaft bearing surface.

Caution

- Do not apply engine oil to the bearing cap installation surface and back surface of the bearing.

13) Install the thrust bearings to the front and rear sides of bearing cap No. 4.

Legend

- Thrust bearing

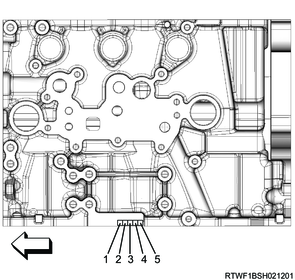

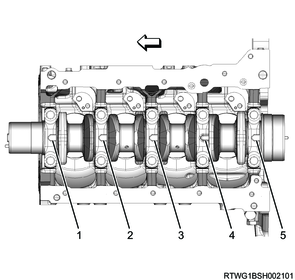

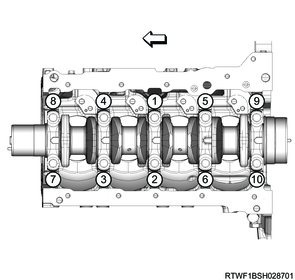

14) Install the bearing caps to the cylinder block in the order shown in the diagram.

Note

- Install so that the bearing cap front mark faces the front of the engine.

Legend

- No. 1

- No. 2

- No. 3

- No. 4

- No. 5

15) Apply engine oil to the threaded portions and seating surfaces of the bolts.

16) Tighten the bearing cap bolts to the cylinder block in the order shown in the diagram.

Caution

- Do not reuse the bearing cap bolt.

However, only when a new bearing cap bolt is used to measure the oil clearance, the bearing cap bolt can be reused.

Tightening torque: 50 N・m { 5.1 kgf・m / 36.9 lb・ft } 1st time

Tightening Angle : 60 to 90 ° 2nd time

17) Confirm that the crankshaft turns smoothly.

Caution

- After installing the piston and connecting rod, rotate the crankshaft and make sure that there is no interference with the oil jet.