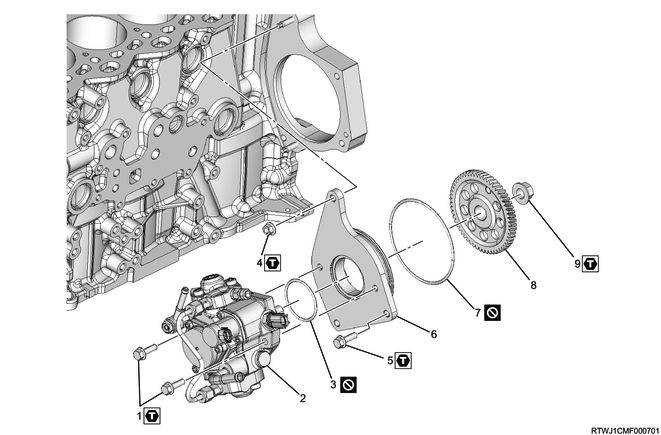

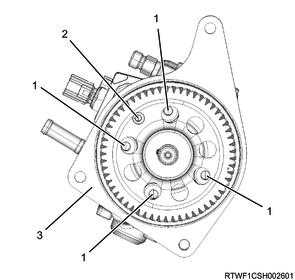

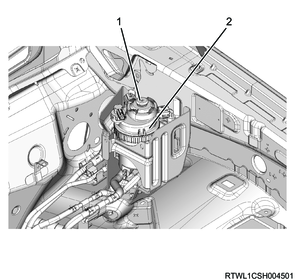

1. Component views

Fuel supply pump

Part name

- Bolt

- Fuel supply pump

- O-ring

- Nut

- Bolt

- Supply pump bracket

- O-ring

- Supply pump gear

- Supply pump gear nut

Tightening torque

1: 25 N・m { 2.5 kgf・m / 18 lb・ft }

4: 25 N・m { 2.5 kgf・m / 18 lb・ft }

5: 25 N・m { 2.5 kgf・m / 18 lb・ft }

9: 63.7 N・m { 6.5 kgf・m / 47 lb・ft }

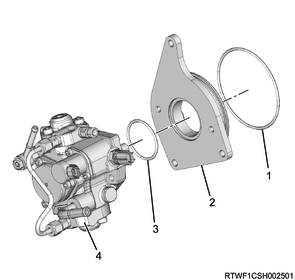

2. Fuel supply pump installation

1) Apply engine oil to the O-ring.

2) Install the O-ring to the fuel supply pump.

3) Install the O-ring to the adapter.

Legend

- O-ring

- Adapter

- O-ring

- Fuel supply pump

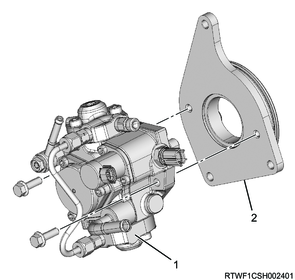

4) Install the fuel supply pump to the adapter.

Caution

- Do not pinch the O-ring.

Tightening torque: 25 N・m { 2.5 kgf・m / 18 lb・ft }

Legend

- Fuel supply pump

- Adapter

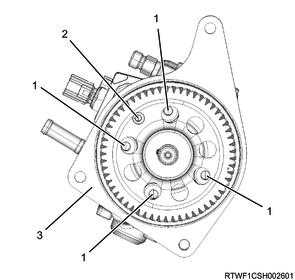

5) Temporarily tighten the supply pump gear to the fuel supply pump.

6) Use bolts to secure the supply pump gear to the adapter.

Note

- Use M8 x 1.25 bolts with a length of 35 mm {1.38 in} or more.

Caution

- Secure the bolts and adapter in 3 or more locations.

Legend

- Supply pump gear securing holes

- Lock bolt hole

- Adapter

7) Final tighten the supply pump gear to the fuel supply pump.

Tightening torque: 63.7 N・m { 6.5 kgf・m / 47 lb・ft }

8) Remove the bolts from the adapter.

9) Install the M6 lock bolt to the adapter.

Legend

- Supply pump gear securing holes

- Lock bolt hole

- Adapter

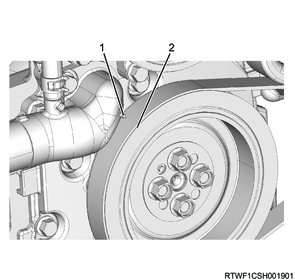

10) Rotate the crankshaft in the forward direction (clockwise) to align the No. 1 cylinder piston to compression top dead center.

Legend

- Top dead center alignment mark on the water inlet pipe side

- Top dead center alignment mark on the crank pulley side

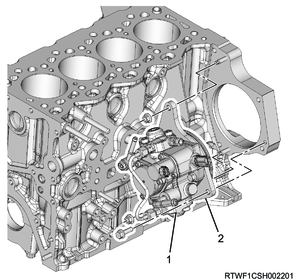

11) Install the fuel supply pump and adapter to the cylinder block.

Tightening torque: 25 N・m { 2.5 kgf・m / 18 lb・ft }

Legend

- Fuel supply pump

- Adapter

12) Remove the plug from the flywheel housing.

Legend

- Plug

- Flywheel housing

- Fuel supply pump

13) Remove the lock bolt from adapter.

14) Install the plug to the flywheel housing.

Caution

- Do not reuse the gasket.

Tightening torque: 63 N・m { 6.4 kgf・m / 46 lb・ft }

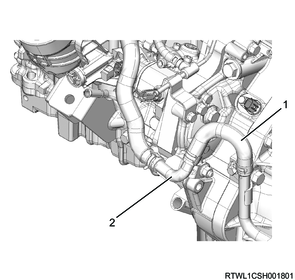

15) Connect the fuel leak-off hose to the fuel supply pump.

16) Connect the fuel suction hose to the fuel supply pump.

Legend

- Fuel leak-off hose

- Fuel suction hose

17) Connect the connector to the FRP regulator.

18) Connect the connector to the fuel temperature sensor.

Legend

- FRP regulator connector

- Fuel temperature sensor connector

3. Water pipe installation

1. Automatic transmission models

1) Install the water pipe and EGR cooler water hose as a set to the flywheel housing.

Tightening torque: 52 N・m { 5.3 kgf・m / 38 lb・ft }

Legend

- EGR cooler water pipe B

- Nut

- Water pipe

- EGR cooler water hose

2) Connect the EGR cooler water hose to EGR cooler water pipe B.

3) Connect the ATF water hose to the water pipe.

Legend

- ATF water hose

- Water pipe

4. Fuel feed pipe installation

1) Install the fuel feed pipe to the fuel supply pump and common rail (fuel rail).

Caution

- Do not reuse the fuel feed pipe.

Tightening torque: 35 N・m { 3.6 kgf・m / 26 lb・ft }

Legend

- Fuel feed pipe

2) Install the clip to the fuel feed pipe.

Tightening torque: 10.0 N・m { 1.0 kgf・m / 89 lb・in }

5. Inlet cover installation

6. Starter motor installation

7. Fuel air bleed

1) Open the engine hood.

2) Press the priming pump until it becomes hard.

Caution

- Completely bleed air, as insufficient air bleeding may lead to engine malfunctions.

Legend

- Priming pump

- Fuel filter with sedimenter

8. ECM setting

Note

- If repairing or replacing the fuel supply pump, perform Fuel Supply Pump Relearning.

1. Fuel Supply Pump Relearning

1) Connect the scan tool to the DLC.

2) Turn ON the ignition switch.

3) Select the scan tool item.

- Diagnostics > Engine > RZ4E > Special Function > Fuel Supply Pump Learn Resetting

4) Reset the Fuel Supply Pump Learning by following the on-screen instructions.

5) Turn OFF the ignition switch for 30 seconds.

6) Start and idle the engine until the engine coolant temperature reaches 65°C {149°F} or more.

7) Observe the Fuel Supply Pump Status parameter on the scan tool.

8) The procedure is complete when the parameter changes from Not Learned to Learned.