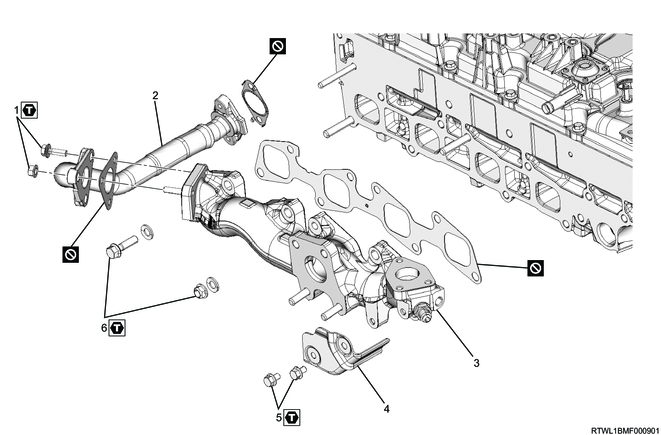

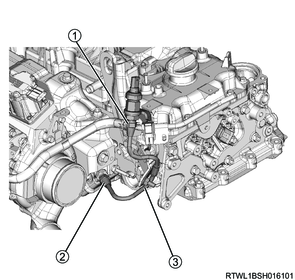

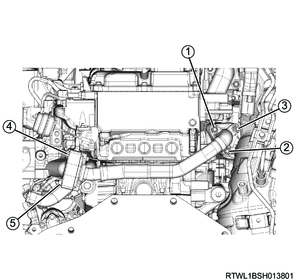

1. Component views

Exhaust manifold

Part name

- Nut and bolt

- EGR cooler bypass pipe

- Exhaust manifold

- Heat protector

- Bolt

- Nut and bolt

Tightening torque

1: 27 N・m { 2.8 kgf・m / 20 lb・ft }

5: 25 N・m { 2.5 kgf・m / 18 lb・ft }

6: 52 N・m { 5.3 kgf・m / 38 lb・ft }

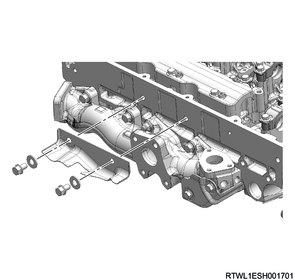

2. Exhaust manifold installation

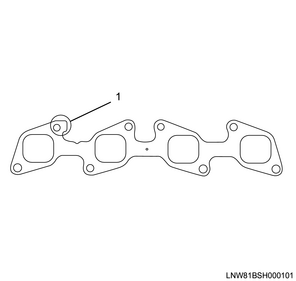

1) Install the gasket to the cylinder head.

Note

- Face the gasket protruding portion to the cylinder head rear side.

Caution

- Do not reuse the gasket.

Legend

- Protrusion

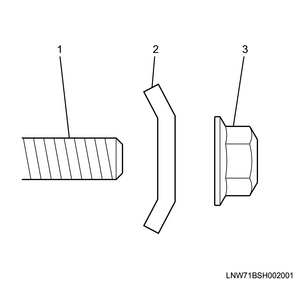

2) Referring to the diagram, temporarily tighten the exhaust manifold to the cylinder head.

Legend

- Stud bolt

- Washer

- Nut

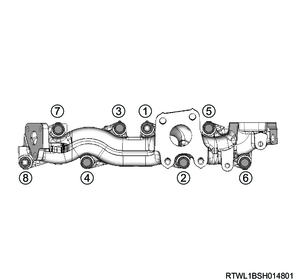

3) Final tighten the exhaust manifold to the cylinder head in the order shown in the diagram.

Tightening torque: 52 N・m { 5.3 kgf・m / 38 lb・ft }

Caution

- Do not over-tighten since it will expand or contract due to the heat of the manifold.

4) Install the exhaust manifold heat protector to the exhaust manifold.

Tightening torque: 25 N・m { 2.5 kgf・m / 18 lb・ft }

5) Install the differential pressure sensor heat protector to the cylinder head.

Tightening torque: 51 N・m { 5.2 kgf・m / 38 lb・ft }

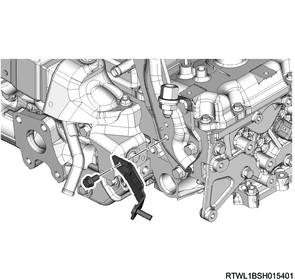

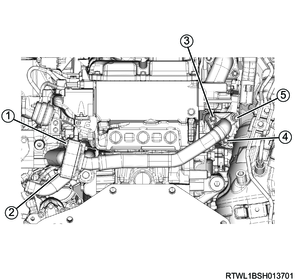

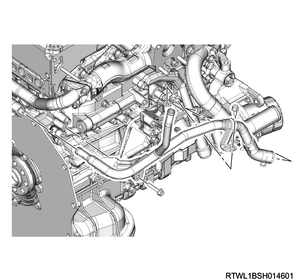

3. EGR gas pressure pipe installation

1) Install the EGR gas pressure sensor bracket to the cylinder head.

Tightening torque: 25 N・m { 2.5 kgf・m / 18 lb・ft }

2) Install the EGR gas pressure pipe to the exhaust manifold and bracket in the order shown in the diagram.

Caution

- If there is looseness in the nipple, further tighten it when installing the flare nut

Tightening torque: 55 N・m { 5.6 kgf・m / 41 lb・ft } Nipple

Tightening torque: 32 N・m { 3.3 kgf・m / 24 lb・ft } Flare nut

Tightening torque: 25 N・m { 2.5 kgf・m / 18 lb・ft } Clip nut

Legend

- Flare nut

- Nipple

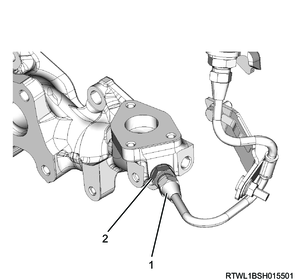

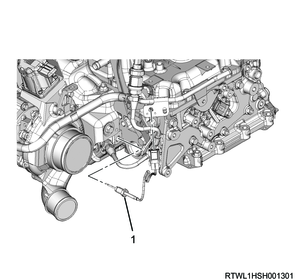

4. EGR gas temperature sensor 1 (exhaust manifold side) installation

1) Clean the old anti-seize lubricant on the sleeve nut, and apply new anti-seize lubricant to the threaded portion of the EGR gas temperature sensor sleeve nut.

Note

- If EGR gas temperature sensor 1 is replaced with a new one, it is not necessary to apply new anti-seize lubricant.

Caution

- Apply Never-Seez High Temperature Stainless Grade 5-87411-039-0 by Bostik of USA as the anti-seize lubricant.

2) Install EGR gas temperature sensor 1 (exhaust manifold side) to the exhaust manifold.

Tightening torque: 44 N・m { 4.5 kgf・m / 32 lb・ft }

Legend

- EGR gas temperature sensor 1 (Exhaust manifold side)

3) Connect the connector to EGR gas temperature sensor 1 (exhaust manifold side).

4) Install the sensor connector to the water pipe.

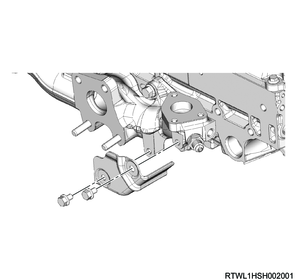

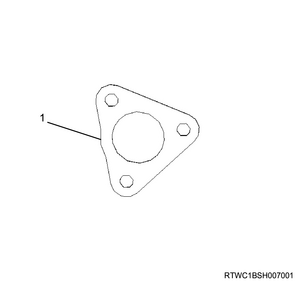

5. EGR cooler bypass pipe installation

1) Temporarily tighten the EGR cooler bypass pipe and gasket to the inlet manifold and exhaust manifold in the order shown in the diagram.

Caution

- Do not reuse the gasket.

- Install the exhaust manifold side gasket with the protrusion facing toward the engine.

Legend

- Protrusion

2) Final tighten the EGR cooler bypass pipe to the inlet manifold and exhaust manifold in the order shown in the diagram.

Tightening torque: 27 N・m { 2.8 kgf・m / 20 lb・ft }

6. EGR water pipe installation

1) Install the EGR water pipe to the oil cooler and turbocharger lower bracket.

Tightening torque: 25 N・m { 2.5 kgf・m / 18 lb・ft }

2) Connect the water hose to the water intake pipe and return hose.