1. Component views

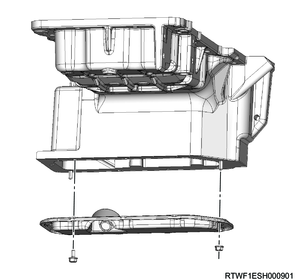

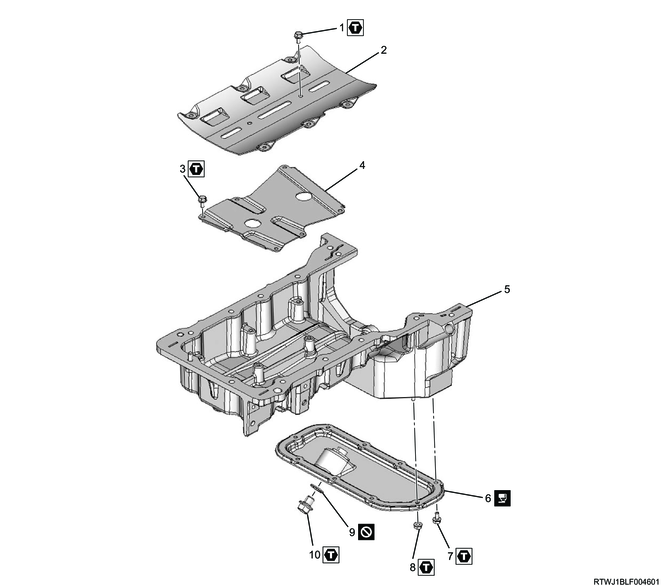

Crankcase

Part name

- Bolt

- Upper crankcase plate

- Bolt

- Lower crankcase plate

- Crankcase

- Oil pan

- Bolt

- Nut

- Gasket

- Drain bolt

Tightening torque

1: 10.0 N・m { 1.0 kgf・m / 89 lb・in }

3: 10.0 N・m { 1.0 kgf・m / 89 lb・in }

7: 10.0 N・m { 1.0 kgf・m / 89 lb・in }

8: 10.0 N・m { 1.0 kgf・m / 89 lb・in }

10: 83.3 N・m { 8.5 kgf・m / 61 lb・ft }

2. Crankcase installation

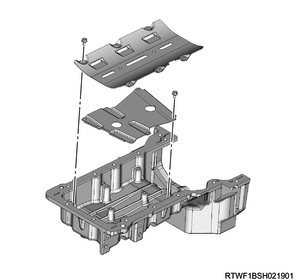

1) Install the baffle plate to the crankcase.

Tightening torque: 10.0 N・m { 1.0 kgf・m / 89 lb・in }

2) Referring to the diagram, apply ThreeBond 1207B to the crankcase.

Standard: 4.0 to 5.0 mm { 0.157 to 0.197 in } Bead width

Standard: 2.0 to 3.0 mm { 0.079 to 0.118 in } Bead height

Caution

- Install the crankcase within 5 minutes of applying the liquid gasket.

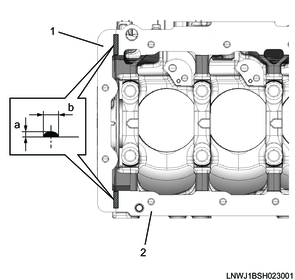

3) Referring to the diagram, apply ThreeBond 1207B to the cylinder block and front cover mating surface.

Legend

- Front cover

- Cylinder block

Standard value

a: 2.0 to 3.0 mm { 0.079 to 0.118 in } Bead height

b: 4.0 to 5.0 mm { 0.157 to 0.197 in } Bead width

4) Install the crankcase to the cylinder block.

Caution

- Carefully wipe away any gasket that has leaked out from between the aligning surfaces of the cylinder block and crankcase.

Tightening torque: 25 N・m { 2.5 kgf・m / 18 lb・ft }

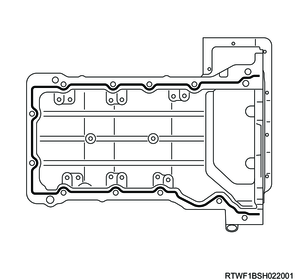

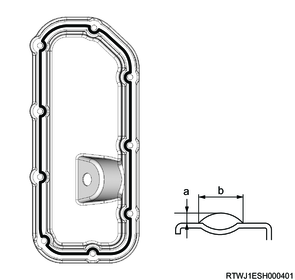

3. Oil pan installation

1) Referring to the diagram, apply ThreeBond 1207B or equivalent to the oil pan.

Caution

- After applying the liquid gasket, install the oil pan within 5 minutes.

Standard value

a: 2.0 to 3.0 mm { 0.079 to 0.118 in } Bead height

b: 4.0 to 5.0 mm { 0.157 to 0.197 in } Bead width

2) Install the oil pan to the crankcase.

Tightening torque: 10.0 N・m { 1.0 kgf・m / 89 lb・in }