1. Maintenance precautions of brake

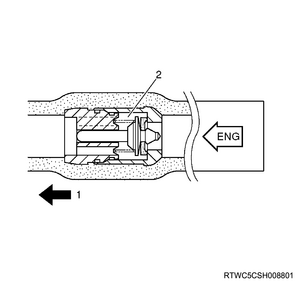

1. Vacuum hose installation direction

When attaching the vacuum hose to vehicles with a check valve, make sure the arrow painted on the hose is pointing to the engine side.

Legend

- Engine side

- Check valve

2. About steering angle sensor learning (Models equipped with ESC)

If any of the following are met, the steering angle sensor learning must be performed. Refer to Steering angle sensor setting in the workshop manual.

- The steering angle sensor is replaced.

- The steering related parts are replaced.

Refer to "6.Steering 6Z.Steering Electrical Control steering angle sensor setting".

3. Using circuit test tools

Unless instructed in the diagnostic procedure, do not use a test lamp. When a probe connector is required in the diagnostic procedure, use connector test adapter kit 5-8840-2835-0.

4. Safety precautions

When performing an inspection using a scan tool with the engine ON in a closed location such as a garage, make sure to adequately ventilate the area. Before performing a vehicle inspection test using a scan tool, firmly engage the parking brake, and stabilize the vehicle using chock blocks.

5. Commercial electronic equipment

Aftermarket electronic equipment refers to commercially available electronic equipment installed to the vehicle after it has been shipped from the factory. Be careful because they are not taken into particular consideration at the vehicle design stage.

Aftermarket electronic equipment may cause malfunctions in the electronic control system, even if the equipment is usually installed. Therefore when diagnosing the electronic system, first confirm whether such aftermarket electronic equipment is installed, and if installed, remove it from the vehicle to check its effect to the malfunction.

Caution

- Make sure that both the power supply and ground of aftermarket electronic equipment are connected to a circuit that is not affected by the electronic control system.

6. Damage caused by electrostatic discharge

Because the electronic components used in the electronic control system are designed to operate at extremely low voltages, they can be easily damaged by electrostatic discharge, and can be damaged by static electricity of 100 V or less, which cannot be felt by a person. The most common causes of electrostatic charge build-up for a person are friction and induction. It is easy for a person to build an electrostatic charge by friction when they slide across the seat of a vehicle. A person wearing insulated shoes can easily build an electrostatic charge by induction if they momentarily touch the ground while standing near a highly charged object. A charge of the same polarity flows out, and with a highly opposing polarity, that person becomes charged. Be careful because static electricity causes damage to electronic components.

Caution

- To prevent damage caused by electrostatic discharge, do not touch the connector pins of the control unit or the electronic components soldered onto the circuit board of the control unit.

- To prevent damage caused by electrostatic discharge, do not open the package of a replacement part until the preparations for installation of the part are completed.

- To prevent damage caused by electrostatic discharge, connect the package to the vehicle ground to discharge the static electricity, before removing the part from the package.

7. Control unit maintenance precautions

Make sure that the circuit does not overload so much as to affect the control unit. When testing for an open circuit and short circuit, do not ground or apply voltage to the control unit circuit unless instructed to do so. Also, when performing these circuit tests, make sure to use a DMM with a large input impedance.