1. Shift on the fly system inspection

1. Visual inspection

1) Inspect the shift-on-the-fly actuator for the following.

- Wear

- Damage

- Cracking

- Other malfunctions

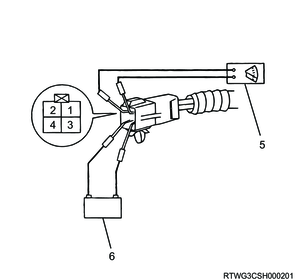

2) Apply voltage to shift-on-the-fly actuator terminals 3 and 4.

Standard: 12 V Voltage to be applied

3) Connect a tester to terminal 1 and terminal 2, and inspect the shift-on-the-fly actuator operation according to the following table.

Legend

- Terminal 1

- Terminal 2

- Terminal 3

- Terminal 4

- Tester

- Battery

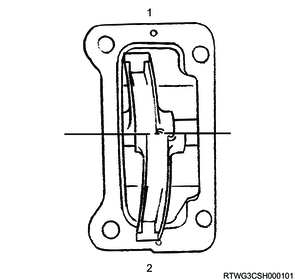

Legend

- Condition A

- Condition B

Legend

- Shift drum

- Direction C

- Direction D

| Condition |

Terminal 3 electrode |

Terminal 4 electrode |

Continuity between terminals 1 and 2 |

Operation direction |

| Condition A |

+ |

- |

○ |

Direction C |

| Condition B |

- |

+ |

× |

Direction D |

Caution

- Prevent the shift-on-the-fly actuator terminal section from water or dirt adhesion.

- Do not reuse shift-on-the-fly actuators that have opened covers.

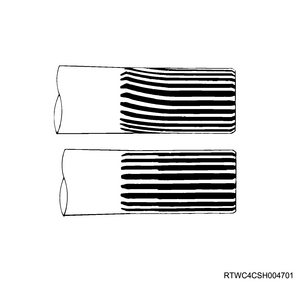

2. Inner axle shaft measurement

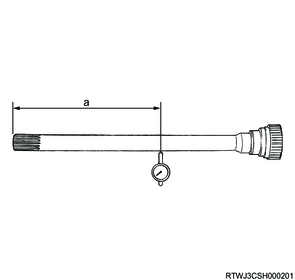

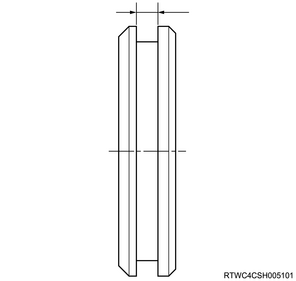

1) Support the center of both ends of the inner axle shaft.

2) Measure the runout of the inner axle shaft using a dial gauge.

Note

- Slowly rotating the inner axle shaft, measure the runout at the location shown in the following diagram.

Measurement position

a: 230 mm { 9.06 in }

Caution

- When repairing bends in the shaft, heat should never be used.

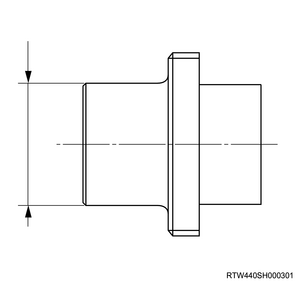

3. Sleeve measurement

1) Measure the width of the sleeve center groove.

Limit: 7.1 mm { 0.28 in }

4. Clutch gear measurement

1) Measure the clutch gear outer diameter.

Limit: 36.98 mm { 1.456 in }

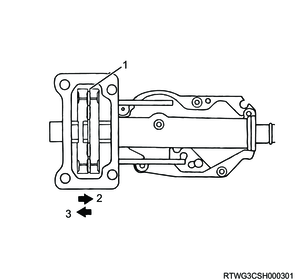

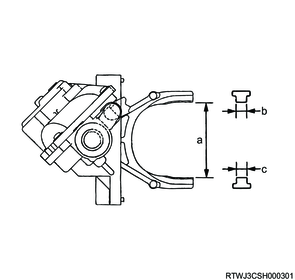

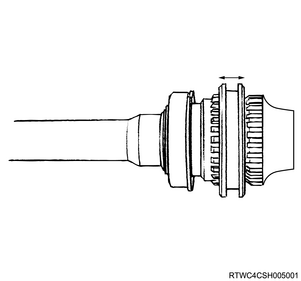

5. Shift-on-the-fly actuator measurement

1) Measure the shift-on-the-fly actuator dimension.

Limit

a: 64.3 mm { 2.53 in }

b: 6.7 mm { 0.26 in }

c: 6.7 mm { 0.26 in }

2. Inner drive shaft inspection

When inspecting, if nothing in particular is specified, refer to the following and apply shift-on-the-fly system oil.

Refer to "201.General Information 14B.Vehicle Information recommended fluids, lubricants and diesel fuels".

1) Inspect the inner axle shaft for the following.

- Wear

- Damage

- Twisted spline section

- Worn spline section

- Cracked spline section

- Gear sleeve sliding section malfunction

Note

- Replace the inner axle shaft if a malfunction is found.

2) Inspect the sleeve for the following.

- Wear

- Damage

- Cracking

- Smooth operation on the clutch gear

Note

- When performing the clutch gear operation inspection, apply shift-on-the-fly system oil to the sleeve inner gear contact surface.

- Replace the sleeve if a malfunction is found.

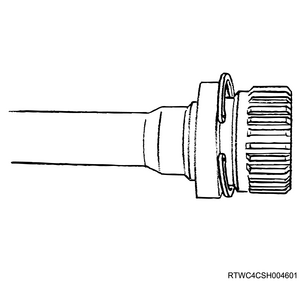

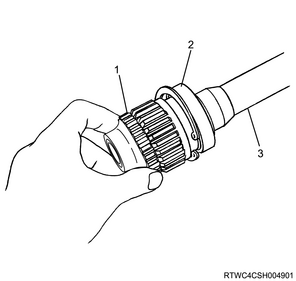

3) Inspect the inner shaft bearing for smooth rotation.

Note

- Insert the clutch gear into the inner axle shaft to rotate it, and inspect the inner shaft bearing status.

- Replace the bearing if an abnormal condition such as unsmooth bearing sliding is found.

Legend

- Clutch gear

- Inner shaft bearing

- inner axle shaft

4) Inspect the clutch gear for the following.

- Worn clutch gear

- Damaged clutch gear

- Cracked clutch gear

- Unsmooth operation when operating together with the sleeve

- Other abnormal conditions

Note

- When inspection of operation together with the sleeve is performed, apply shift-on-the-fly system oil to the clutch gear contact surface.

- Replace the clutch gear if a malfunction is found.