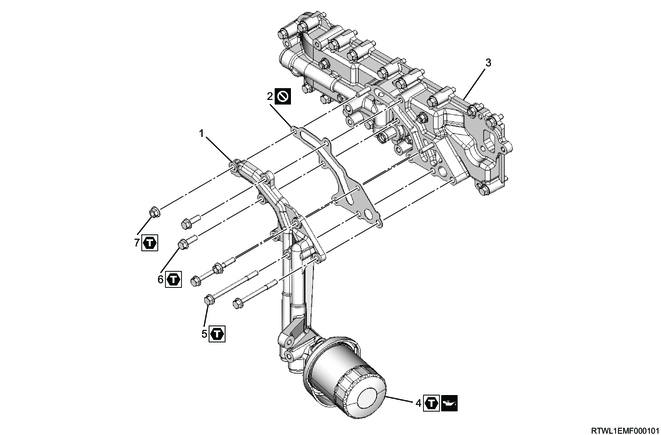

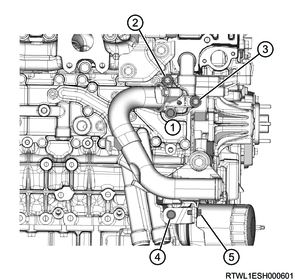

1. Component views

Oil filter

Part name

- Oil filter

- Gasket

- Oil cooler

- Oil filter element

- Bolt

- Bolt

- Nut

Tightening torque

4: 19.6 N・m { 2.0 kgf・m / 14 lb・ft }

5: 25 N・m { 2.5 kgf・m / 18 lb・ft }

6: 25 N・m { 2.5 kgf・m / 18 lb・ft }

7: 25 N・m { 2.5 kgf・m / 18 lb・ft }

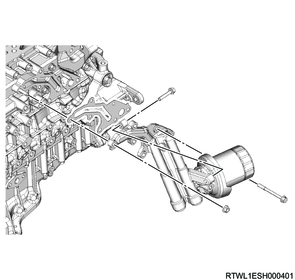

2. Oil filter installation

1) Temporarily tighten the oil filter and gasket to the oil cooler in the order shown in the diagram.

Caution

- Do not reuse the gasket.

- Ensure that no dirt or foreign material enters.

2) Final tighten the oil filter to the oil cooler in the order shown in the diagram.

Tightening torque: 25 N・m { 2.5 kgf・m / 18 lb・ft }

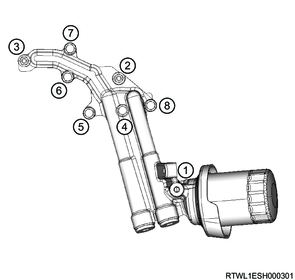

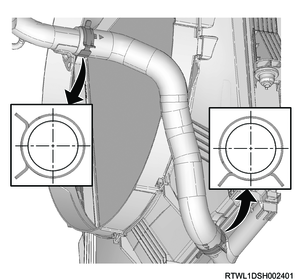

3. Water intake pipe installation

1) Temporarily tighten the water intake pipe and water hose to the oil cooler in the order shown in the diagram.

Caution

- Do not reuse the gasket.

2) Final tighten the water intake pipe and water hose to the oil cooler in the order shown in the diagram.

Tightening torque: 25 N・m { 2.5 kgf・m / 18 lb・ft }

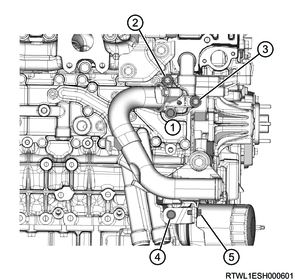

4. EGR water pipe installation

1) Install the EGR water pipe to the oil cooler and turbocharger lower bracket.

Tightening torque: 25 N・m { 2.5 kgf・m / 18 lb・ft }

2) Connect the water hose to the water intake pipe and return hose.

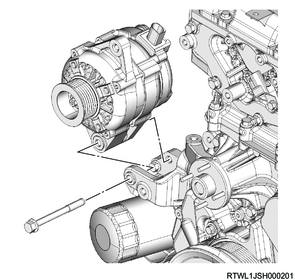

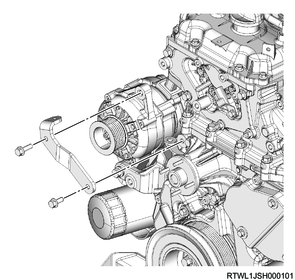

5. Generator installation

1) Install the generator to the lower bracket.

Tightening torque: 40 N・m { 4.1 kgf・m / 30 lb・ft }

2) Install the upper bracket to the generator and timing gear case.

Tightening torque: 25 N・m { 2.5 kgf・m / 18 lb・ft }

3) Connect the connector to the generator.

4) Connect the B-terminal to the generator.

Tightening torque: 12 N・m { 1.2 kgf・m / 106 lb・in }

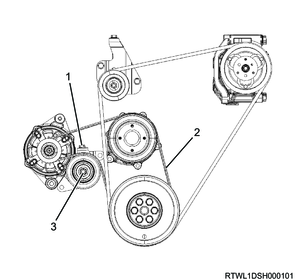

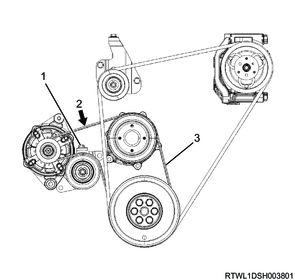

6. Cooling fan belt installation

1) Install the cooling fan belt to the following parts.

- Fan pulley

- Generator

- Crankshaft pulley

Legend

- Adjust bolt

- Cooling fan belt

- Lock nut

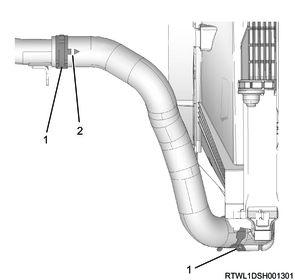

7. Radiator lower hose connect

1) Connect the radiator lower hose and clamp to the water intake pipe.

Note

- Insert the lower hose until it makes full contact with the pipe.

- Soapy water can be applied when installing the lower hose.

Legend

- Clamp

- Arrow mark

Note

- Align the clamp with the lower hose arrow mark end to install.

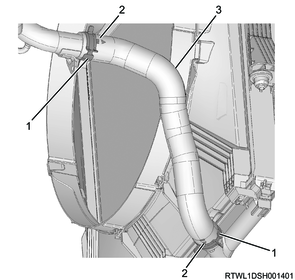

Legend

- Clamp

- Arrow mark

- Radiator lower hose

Note

- Install the clamp in the direction shown in the following diagram.

- The diagram about the clamp direction shows the state viewed from the vehicle front.

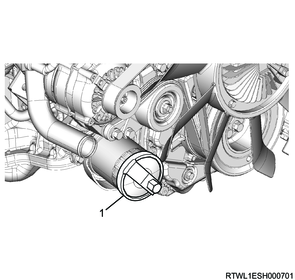

8. Oil filter element installation

1) Clean the oil filter mounting surface.

2) Apply grease or engine oil to the oil filter element seal section.

3) Install the oil filter element to the oil filter bracket using the special tool.

SST: 5-8840-0203-0 - oil filter wrench

Tightening torque: 19.6 N・m { 2.0 kgf・m / 14 lb・ft }

Legend

- 5-8840-0203-0

9. Turbocharger installation

10. Cooling fan belt adjustment

When installing a new belt, initial stretching of the belt occurs.

In addition, when reusing the belt, the belt needs to be fitted to the pulley groove.

After fitting the cooling fan belt, readjust the cooling fan belt tension.

1) Loosen the tension pulley lock nut using a wrench.

2) Adjust the cooling fan belt tension by turning the adjust bolt.

Note

- The standard amount of deflection shown is the value obtained when the standard pressure is applied to the midpoint of the fan pulley and generator.

Standard: 98 N { 10.0 kg / 22 lb }

Caution

- Accurately adjust the tension as there is a possibility the service life of the belt may be shortened or belt squeal may be generated if the tension is not within the appropriate range.

- Use a sonic tension meter to verify accurate tension adjustment.

| Adjustment conditions |

Deflection |

Vibration frequency |

| When new |

5.0 to 6.0 mm { 0.20 to 0.24 in } |

207 to 231 Hz |

| Reused |

7.0 to 7.8 mm { 0.28 to 0.31 in } |

176 to 190 Hz |

Legend

- Tension pulley adjust bolt

- Measurement point

- Cooling fan belt

3) Tighten the tension pulley lock nut to the specified torque.

Tightening torque: 41 N・m { 4.2 kgf・m / 30 lb・ft }