|

ac5wzw00013294

DTC P2588:00 [PCM (SKYACTIV-D 2.2)]

id0102j5220800

Details on DTCs

|

System malfunction location |

Variable turbine geometry turbocharger actuator position sensor: Low input |

|

|---|---|---|

|

Detection conditions

|

Determination condition

|

• The output voltage of the variable turbine geometry turbocharger actuator position sensor is lower than 0.233 V for a continuous 1.5 s.

|

|

Preconditions

|

• All of the following conditions are met.

|

|

|

Drive cycle

|

• 1

|

|

|

Self-test type

|

• CMDTC self test

|

|

|

Sensor/unit used

|

• Variable turbine geometry turbocharger actuator position sensor

|

|

|

Fail-safe

|

• Limits engine torque.

• Inhibits the automatic diesel particulate filter regeneration control.

• Inhibits the manual diesel particulate filter regeneration control.

• Inhibits the boost control.

• Inhibits the EGR control.

• Stops the G-vectoring control (GVC).

• Limits the engine transaxle total control.

|

|

|

Vehicle status when DTCs are output

|

• Check engine light turns on

|

|

|

Possible cause

|

• Variable turbine geometry turbocharger actuator connector or terminal malfunction

• PCM connector or terminal malfunction

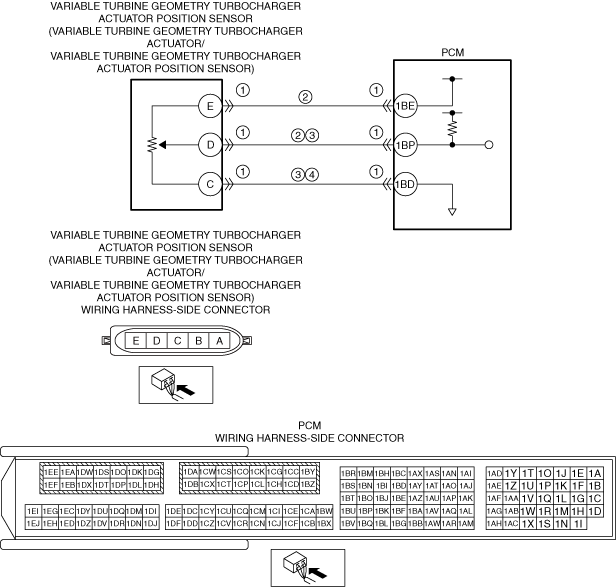

• Short to ground in wiring harness between the following terminals:

• Short circuit in variable turbine geometry turbocharger actuator position sensor signal circuit and ground circuit

• Open circuit in wiring harness between variable turbine geometry turbocharger actuator position sensor terminal C and PCM terminal 1BD

• Variable turbine geometry turbocharger actuator position sensor malfunction

• PCM malfunction

|

|

System Wiring Diagram

ac5wzw00013294

|

Function Explanation (DTC Detection Outline)

Repeatability Verification Procedure

PID Item/Simulation Item Used in Diagnosis

PID

|

Item name |

Outline |

Unit |

Display/condition |

|---|---|---|---|

|

VGTURB_ACT

|

Variable turbine geometry turbocharger actuator position

|

%

|

• Displays the variable turbine geometry turbocharger actuator position.

|

Simulation item

|

Item name |

Outline |

Unit |

Display/condition |

|---|---|---|---|

|

VGTURB_DSD

|

Variable turbine geometry turbocharger actuator position

|

%

|

• Changes % and forcibly drives/stops the variable turbine geometry turbocharger actuator.

|

Function Inspection Using M-MDS

|

Step |

Inspection |

Results |

Action |

|---|---|---|---|

|

1

|

PURPOSE: RECORD VEHICLE STATUS AT TIME OF DTC DETECTION TO UTILIZE WITH REPEATABILITY VERIFICATION

• Record the freeze frame data/snap shot data.

|

—

|

Go to the next step.

|

|

2

|

PURPOSE: DETERMINE IF MALFUNCTION IS CAUSED BY VARIABLE TURBINE GEOMETRY TURBOCHARGER ACTUATOR POSITION SENSOR

• Inspect the variable turbine geometry turbocharger actuator position sensor.

• Is the variable turbine geometry turbocharger actuator position sensor normal?

|

Yes

|

Go to the troubleshooting procedure to perform the procedure from Step 1.

|

|

No

|

Inspect the related wiring harnesses and connectors.

• Repair or replace the malfunctioning location.

Go to the troubleshooting procedure to perform the procedure from Step 5.

|

Troubleshooting Diagnostic Procedure

|

Step |

Inspection |

Results |

Action |

|---|---|---|---|

|

1

|

PURPOSE: VERIFY IF CONNECTOR DAMAGE OF EACH PART AFFECTS DIAGNOSTIC RESULTS

• Switch the ignition OFF.

• Disconnect the connectors of the following parts:

• Inspect the connector engagement and connection condition, and inspect the terminals for damage, deformation, corrosion, or disconnection.

• Is the connector normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the connector, then go to Step 5.

|

||

|

2

|

PURPOSE: VERIFY IF SHORT TO GROUND IN VARIABLE TURBINE GEOMETRY TURBOCHARGER ACTUATOR POSITION SENSOR POWER SUPPLY CIRCUIT AFFECTS DIAGNOSTIC RESULTS

• Verify that the variable turbine geometry turbocharger actuator position sensor connector and the PCM connector are disconnected.

• Inspect for continuity between the following terminals (vehicle wiring harness side) and ground.

• Is there continuity?

|

Yes

|

Refer to the wiring diagram and verify if there is a common connector between the following terminals.

• Variable turbine geometry turbocharger actuator position sensor terminal E and PCM terminal 1BE

• Variable turbine geometry turbocharger actuator position sensor terminal D and PCM terminal 1BP

If there is a common connector:

If there is no common connector:

Go to the next step.

|

|

No

|

Go to the next step.

|

||

|

3

|

PURPOSE: VERIFY IF SHORT CIRCUIT IN VARIABLE TURBINE GEOMETRY TURBOCHARGER ACTUATOR POSITION SENSOR SIGNAL CIRCUIT AND GROUND CIRCUIT AFFECTS DIAGNOSTIC RESULTS

• Verify that the variable turbine geometry turbocharger actuator position sensor connector and the PCM connector are disconnected.

• Inspect for continuity between variable turbine geometry turbocharger actuator position sensor terminals D and C (vehicle wiring harness side).

• Is there continuity?

|

Yes

|

Refer to the wiring diagram and verify if there is a common connector between the following terminals.

• Variable turbine geometry turbocharger actuator position sensor terminal D and PCM terminal 1BP

• Variable turbine geometry turbocharger actuator position sensor terminal C and PCM terminal 1BD

If there is a common connector:

If there is no common connector:

Go to Step 5.

|

|

No

|

Go to the next step.

|

||

|

4

|

PURPOSE: VERIFY IF OPEN CIRCUIT IN VARIABLE TURBINE GEOMETRY TURBOCHARGER ACTUATOR POSITION SENSOR POWER SUPPLY CIRCUIT AFFECTS DIAGNOSTIC RESULTS

• Verify that the variable turbine geometry turbocharger actuator connector and the PCM connector are disconnected.

• Inspect the wiring harness for continuity between variable turbine geometry turbocharger actuator position sensor terminal C and PCM terminal 1BD (vehicle wiring harness side).

• Is there continuity?

|

Yes

|

Refer to the wiring diagram and verify if there is a common connector between variable turbine geometry turbocharger actuator position sensor terminal C and PCM terminal 1BD.

If there is a common connector:

• Inspect the common connector and terminals for corrosion, damage, or disconnection and the common wiring harnesses for an open circuit to determine the malfunctioning location.

• Repair or replace the malfunctioning location.

If there is no common connector:

• Repair or replace the wiring harness which has an open circuit.

Go to Step 5.

|

|

No

|

Go to the next step.

|

||

|

5

|

PURPOSE: VERIFICATION OF VEHICLE REPAIR COMPLETION

• Reconnect all disconnected connectors and hoses.

• Refer to the [MEMORY CLEARING PROCEDURE] and clear the DTC.

• Implement the repeatability verification procedure.

• Display the DTCs using the M-MDS.

• Is DTC P2588:00 displayed?

|

Yes

|

Repeat the inspection from Step 1.

• If the malfunction recurs, replace the PCM, then go to the next step.

|

|

No

|

Go to the next step.

|

||

|

6

|

PURPOSE: VERIFY IF THERE IS ANY OTHER MALFUNCTION

• Has any other DTC or pending code been stored?

|

Yes

|

Repair the malfunctioning location according to the applicable DTC troubleshooting.

|

|

No

|

DTC troubleshooting completed.

|