|

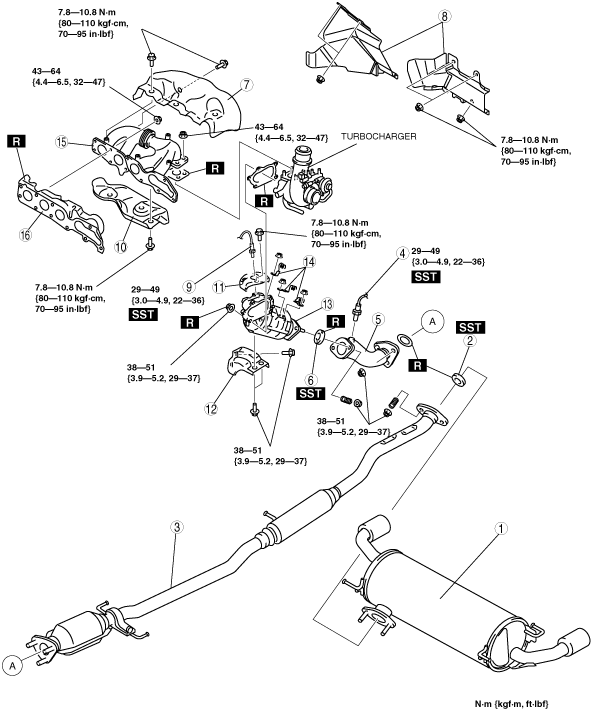

EXHAUST SYSTEM REMOVAL/INSTALLATION [L3 Turbo]

id0115b4800200

1. Disconnect the negative battery cable.

2. Remove the charge air cooler duct.

3. Remove the charge air cooler. (See INTAKE-AIR SYSTEM REMOVAL/INSTALLATION [L3 Turbo])

4. Remove in the order indicated in the table.

5. Install in the reverse order of removal.

acxaaw00000130

|

|

1

|

Main silencer

|

|

2

|

Seal ring (middle pipe side)

(See Seal Ring Removal Note.)

|

|

3

|

Middle pipe

|

|

4

|

HO2S

|

|

5

|

Front pipe

|

|

6

|

Seal ring (WU-TWC side)

(See Seal Ring Removal Note.)

|

|

7

|

Exhaust manifold insulator (Upper) (See Exhaust Manifold Insulator (Upper) Removal Note)

|

|

8

|

Insulator (R.H.D.)

|

|

9

|

A/F sensor

|

|

10

|

Exhaust manifold insulator (Lower)

|

|

11

|

WU-TWC insulator

|

|

12

|

WU-TWC bracket

|

|

13

|

WU-TWC

(See WU-TWC Installation Note.)

|

|

14

|

Clip

|

|

15

|

Exhaust manifold

|

|

16

|

Exhaust manifold gasket

|

Seal Ring Removal Note

1. Remove the seal ring using a flathead screwdriver being careful not to damage the pipe.

acxaaw00000754

|

Exhaust Manifold Insulator (Upper) Removal Note

1. Remove the charge air cooler bracket.

2. Remove the exhaust manifold insulator (upper).

Insulator Removal Note (R.H.D.)

1. Set the blake vacuum hose out of the way. (See VACUUM HOSE REMOVAL/INSTALLATION.)

2. Remove the Insulator.

WU-TWC Removal Note (2WD)

1. Set the generator duct out of the way. (See GENERATOR REMOVAL/INSTALLATION [L3 Turbo].)

2. Remove the WU-TWC.

WU-TWC Removal Note (4WD)

1. Remove the cowl grille.

2. Remove the windshield wiper motor.

3. Remove the cowl panel. (See COWL PANEL REMOVAL/INSTALLATION)

4. Remove the generator duct. (See GENERATOR REMOVAL/INSTALLATION [L3 Turbo])

5. Set the generator out of the way.

6. Remove the WU-TWC.

Exhaust Manifold Installation Note

1. Tighten the exhaust manifold installation nuts in the order shown.

acxaaw00000135

|

WU-TWC Installation Note

1. Temporarily tighten No.1 shown in the figure.

acxaaw00000854

|

2. Temporarily tighten No.2 shown in the figure.

3. Temporarily tighten No.3 shown in the figure.

4. Completely tighten No.1 shown in the figure.

5. Completely tighten No.2 shown in the figure.

6. Completely tighten No.3 shown in the figure.

Seal Ring (WU-TWC Side) Installation Note

1. Temporarily install the seal ring to the pipe so that the seal ring is even with the flange.

acxaaw00000755

|

2. Install the SST to the seal ring so that the SST is even with the flange.

acxaaw00000756

|

3. Press in the seal ring by tapping the SST using a plastic hammer until the seal ring contacts the flange.

acxaaw00000757

|

Front Pipe Installation Note

1. Spray carbon remover (TB6601 or equivalent) on the flared section of the exhaust pipe.

am6zzw00002918

|

2. Remove the carbon adhering to the flared section shown in the figure using a nylon brush or sandpaper (No. 400 or equivalent).

Seal Ring (Middle Pipe Side) Installation Note

1. Temporarily install the seal ring to the pipe so that the seal ring is even with the flange.

acxaaw00000755

|

2. Install the SST to the seal ring so that the SST is even with the flange.

amxuuw00000780

|

3. Press in the seal ring by tapping the SST using a plastic hammer until the seal ring contacts the flange.

amxuuw00000781

|

Main Silencer Installation Note

1. Spray carbon remover (TB6601 or equivalent) on the flared section of the exhaust pipe.

am6zzw00002918

|

2. Remove the carbon adhering to the flared section shown in the figure using a nylon brush or sandpaper (No. 400 or equivalent).