|

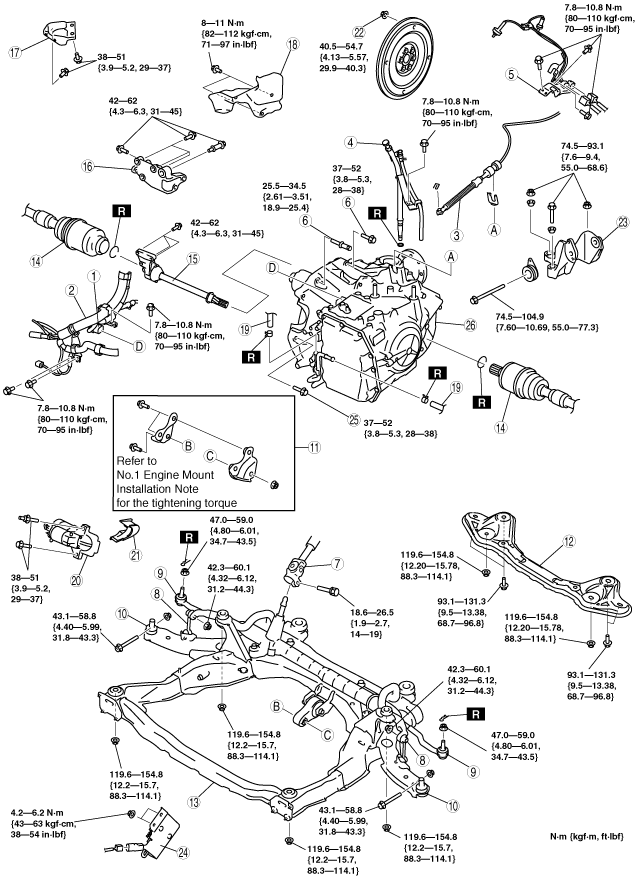

AUTOMATIC TRANSAXLE REMOVAL/INSTALLATION [AW6A-EL, AW6AX-EL]

id051723802400

1. Disconnect the negative battery cable.

2. Remove the following parts.

3. Drain the ATF. (See AUTOMATIC TRANSAXLE FLUID (ATF) REPLACEMENT [AW6A-EL, AW6AX-EL].)

4. Remove in the order shown in the figure.

5. Install in the reverse order of removal.

6. Add ATF to the specified level. (See AUTOMATIC TRANSAXLE FLUID (ATF) REPLACEMENT [AW6A-EL, AW6AX-EL].)

7. Perform the mechanical system test. (See MECHANICAL SYSTEM TEST [AW6A-EL, AW6AX-EL].)

|

Service item |

Test item |

|||

|---|---|---|---|---|

|

Line pressure test |

Stall test |

Time lag test |

Time lag test |

|

|

ATX replacement

|

X

|

|

|

|

|

ATX overhaul

|

X

|

X

|

X

|

X

|

|

Torque converter replacement

|

X

|

X

|

|

|

|

Oil pump replacement

|

X

|

|

|

|

|

Control valve body component

|

X

|

|

|

|

|

Clutch system replacement

|

X

|

|

X

|

X

|

R.H.D.

acxaaw00000789

|

L.H.D.

acxaaw00000790

|

|

1

|

TCM connector

|

|

2

|

Wiring harness bracket

|

|

3

|

Selector cable

|

|

4

|

Oil filler tube, dipstick, breather hose

|

|

5

|

Wiring harness bracket (A/F sensor)

|

|

6

|

Transaxle mounting bolt (Upper side)

|

|

7

|

Steering shaft

|

|

8

|

Stabilizer control link

|

|

9

|

Tie-rod end ball joint

|

|

10

|

Lower arm ball joint

|

|

11

|

No.1 engine mount bracket

|

|

12

|

Crossmember bracket

|

|

13

|

Crossmember

|

|

14

|

Drive shaft

|

|

15

|

Joint shaft (2WD)

|

|

16

|

Transfer bracket (4WD)

|

|

17

|

WU-TWC bracket (4WD)

|

|

18

|

Heat shield (4WD)

|

|

19

|

Oil hose

|

|

20

|

Starter

|

|

21

|

Endplate cover

|

|

22

|

Torque converter installation nuts

|

|

23

|

No.4 engine mount bracket

|

|

24

|

Resistor

|

|

25

|

Transaxle mounting bolt (lower side)

|

|

26

|

Transaxle (2WD)

(See Transaxle Removal Note.)

(See Transaxle Installation Note.)

|

|

Transaxle, transfer and Joint shaft (4WD)

(See Transaxle Removal Note.)

(See Transaxle Installation Note.)

|

acxaaw00000791

|

|

27

|

Joint shaft

|

|

28

|

Transfer

|

|

29

|

Cable bracket

|

|

30

|

Transaxle

|

Torque Converter Nuts Removal Note

1. Align the holes by turning the torque converter.

2. Insert a flathead screwdriver through the converter housing service hole, and lock the drive plate.

acxaaw00000203

|

3. Remove the torque converter nuts.

acxaaw00000204

|

No.4 Engine Mount Bracket Removal Note

1. Install the SST using the following procedure.

acxaaw00000205

|

acxaaw00000206

|

acxaaw00000207

|

2. Support the engine using the SST.

acxaaw00000208

|

3. Remove the No.4 engine mount bracket.

Transaxle Removal Note

1. Support the transaxle on a jack.

acxaaw00000209

|

2. Remove the transaxle mounting bolts.

3. Remove the transaxle.

Transaxle Installation Note

1. Set the transaxle on a jack and lift it.

2. Install the transaxle mounting bolts.

acxaaw00000210

|

No.4 Engine Mount Bracket Installation Note

1. Install the No.4 engine mount bracket to the transaxle and temporarily tighten nuts

acxaaw00000211

|

2. Temporarily tighten bolt D.

3. Temporarily tighten bolt A and nuts B, C.

4. Tighten bolt A, nuts B and C in the order of B→A→C.

5. Tighten bolt D.

No.1 Engine Mount Installation Note

1. Install the No.1 engine mount bracket to the transaxle, then temporarily tighten bolts A and B.

acxaaw00001591

|

2. Install the No.1 engine mount rubber to the bracket, then temporarily tighten bolt C.

3. Tighten the No.1 engine mount bracket bolt A and B in order of A→B.

4. Fully tighten bolt C.

acxaaw00001621

|

Torque Converter Nuts Installation Note

1. Align the holes by turning the torque converter.

2. Insert a screwdriver through the converter housing service hole, and lock the drive plate.

acxaaw00000203

|

3. Tighten the torque converter mounting nuts.

acxaaw00000204

|

Selector Cable Installation Note

1. Install the selector lever to the manual shaft lever so that no load acts on the selector cable.

acxaaw00000213

|

2. Confirm that the tip of the manual shaft lever projects out of the end of the selector cable.