Note

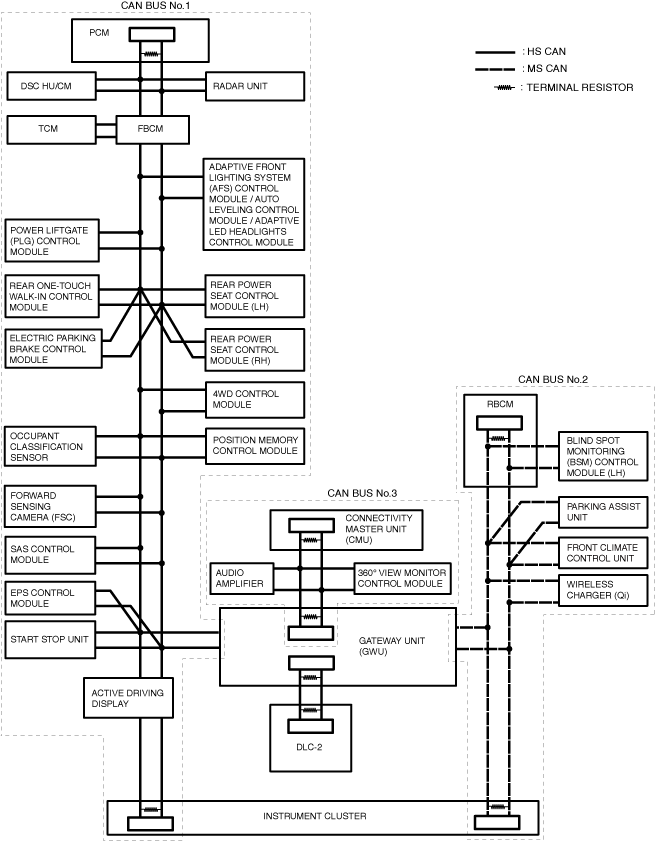

• It is necessary to select the CAN BUS to be diagnosed.Verify the module displayed in red (communication disabled) or blue (communication disabled or module not installed) from the network view on the M-MDS, and select any one CAN BUS between No.1 to 3.

CAN topology

ac8wzn00001384

|