|

1

|

VERIFY FREEZE FRAME DATA HAS BEEN RECORDED

• Has FREEZE FRAME DATA been recorded?

|

Yes

|

Go to the next step.

|

|

No

|

Record FREEZE FRAME DATA on the repair order, then go to the next step.

|

|

2

|

VERIFY RELATED SERVICE INFORMATION AVAILABILITY

• Verify related Service Information availability.

• Is any related Service Information available?

|

Yes

|

Perform repair or diagnosis according to the available Service Information.

• If the vehicle is not repaired, go to the next step.

|

|

No

|

Go to the next step.

|

|

3

|

INSPECT FOR SOURCE OF POTENTIAL HO2S CONTAMINATION

• Investigate the following items as potential sources of HO2S contamination:

-

― Use of unapproved silicon sealers

― Fuel contaminated by silicon additives

― Excessive oil consumption

― Glycol leaking internally in the engine

― Lead-contaminated fuel

― Short drive cycles in cold weather

― Use of unapproved cleaning agents

• Is a concern present?

|

Yes

|

Repair the source of the contamination. Change the engine oil and oil filter. Then go to the next step.

|

|

No

|

Go to the next step.

|

|

4

|

VISUALLY INSPECT HO2S WIRING HARNESS

• Connect the PCM connector.

• Visually inspect the HO2S wiring harness for exposed wiring water contamination, corrosion, and proper assembly.

• Is a concern present?

|

Yes

|

Repair or replace suspected part, then go to Step 12.

|

|

No

|

Go to the next step.

|

|

5

|

INSPECT POWER SUPPLY IN WIRING HARNESS

• Disconnect suspect HO2S connector.

• Turn the ignition switch to the ON position (Engine off).

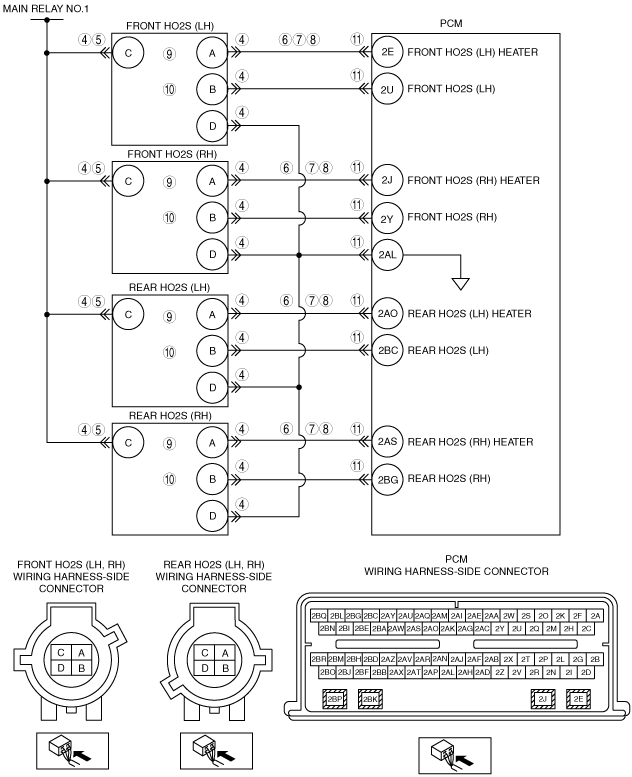

• Measure the voltage between suspect HO2S connector terminal A and C, on the wiring harness side.

• Is the voltage more than 10 V?

|

Yes

|

Turn the ignition switch off. Go to the next step.

|

|

No

|

Repair or replace suspected part. Go to Step 12.

|

|

6

|

INSPECT HO2S HEATER FOR SHORT TO GROUND

• Disconnect the PCM connector.

• Measure the resistance between HO2S terminal A on the wiring harness side and body ground.

• Is the resistance more than 10 kilohms?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace suspected part. Go to Step 12.

|

|

7

|

INSPECT HO2S HEATER FOR SHORT IN WIRING HARNESS

• Measure the resistance between the following terminals:

-

― HO2S terminal A (wiring harness-side) and HO2S terminal C (wiring harness-side)

― HO2S terminal A (wiring harness-side) and HO2S terminal D (wiring harness-side)

― HO2S terminal A (wiring harness-side) and HO2S terminal B (wiring harness-side)

• Are the resistances more than 10 kilohms?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace suspected part. Go to Step 12.

|

|

8

|

INSPECT HO2S HEATER CIRCUIT FOR OPEN CIRCUIT IN WIRING HARNESS

• For DTC P0135, measure the resistance between PCM terminal 2J and front HO2S (RH) terminal A.

• For DTC P0141, measure the resistance between PCM terminal 2AS and rear HO2S (RH) terminal A.

• For DTC P0155, measure the resistance between PCM terminal 2E and front HO2S (LH) terminal A.

• For DTC P0161, measure the resistance between PCM terminal 2AO and rear HO2S (LH) terminal A.

• Is the resistance less than 5.0 ohms?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace suspected part. Go to Step 12.

|

|

9

|

INSPECT INTERNAL RESISTANCE OF HO2S HEATER

• Measure the resistance between the suspect HO2S terminal A and C, on the component side.

• Is the resistance between 3—30 ohms?

|

Yes

|

Go to the next step.

|

|

No

|

Replace HO2S.

Go to Step 12.

|

|

10

|

INSPECT HO2S CASE FOR SHORT TO POWER SUPPLY, HTR, AND SIGNRTN

• Measure the resistance between the suspect HO2S terminal A and D at component side.

• Measure the resistance between the suspect HO2S terminal A and body ground.

• Is the resistance more than 10 kilohms?

|

Yes

|

Go to the next step.

|

|

No

|

Replace HO2S.

Go to the next step.

|

|

11

|

INSPECT FOR CORRECT PCM OPERATION

• Disconnect all the PCM connectors.

• Visually inspect for:

-

― Pushed out pins

― Corrosion

• Connect all the PCM connectors and verify that they seat correctly.

• Retrieve DTCs using the M-MDS.

• Is the PENDING CODE for this DTC present?

|

Yes

|

Go to the next step.

|

|

No

|

The system is correctly. Go to the next step.

|

|

12

|

VERIFY TROUBLESHOOTING OF DTC P0135, P0141, P0155 or P0161 HAS BEEN COMPLETED

• Verify that all disconnected connectors are reconnected.

• Turn the ignition switch to the ON position (Engine off).

• Clear the DTC from the PCM memory using the M-MDS.

• Retrieve DTCs using the M-MDS.

• Is the PENDING CODE for this DTC present?

|

Yes

|

Replace PCM, then go to the next step.

|

|

No

|

Go to the next step.

|

|

13

|

VERIFY AFTER REPAIR PROCEDURE

• Perform “AFTER REPAIR PROCEDURE”.

• Are any DTC present?

|

Yes

|

Go to the applicable DTC inspection.

|

|

No

|

Troubleshooting completed.

|