|

1

|

VERIFY FREEZE FRAME DATA HAS BEEN RECORDED

• Has FREEZE FRAME DATA been recorded?

|

Yes

|

Go to the next step.

|

|

No

|

Record FREEZE FRAME DATA on the repair order, then go to the next step.

|

|

2

|

VERIFY RELATED SERVICE INFORMATION AVAILABILITY

• Verify related Service Information availability.

• Is any related Service Information available?

|

Yes

|

Perform repair or diagnosis according to the available Service Information.

• If the vehicle is not repaired, go to the next step.

|

|

No

|

Go to the next step.

|

|

3

|

VISUALLY INSPECT HO2S HARNESS

• Turn the ignition switch off.

• Disconnect the suspect HO2S connector.

• Visually inspect suspect HO2S for:

-

― Pinched, shorted, and corroded wiring and pins

― Oil or water contamination

― Crossed sensor wires

― Damaged HO2S

• Is a concern present?

|

Yes

|

Repair or replace the malfunctioning part according to the inspection results, then go to Step 11.

|

|

No

|

Go to the next step.

|

|

4

|

CHECK FOR UNMETERED AIR LEAKS

-

Note

-

• Fuel calculations can be affected by unmetered air leaks.

• Carefully inspect the following areas for potential air leaks:

-

― Hoses connecting to the MAF sensor assembly

― Hoses connecting to the throttle body

― Intake manifold gasket leaks

― PCV system

― Vacuum lines are disconnected

― Improperly seated engine oil dipstick, tube or oil fill cap

• Is a concern present?

|

Yes

|

Repair the source of the air leak.

Go to Step 11.

|

|

No

|

Go to the next step.

|

|

5

|

INSPECT FOR SOURCE OF POTENTIAL HO2S CONTAMINATION

• Investigate the following items as potential sources of HO2S contamination:

-

― Use of unapproved silicon sealers

― Fuel contaminated by silicon additives

― Excessive oil consumption

― Glycol leaking internally in the engine

― Lead-contaminated fuel

― Short drive cycles in cold weather

― Use of unapproved cleaning agents

• Is a concern present?

|

Yes

|

Repair the source of the contamination.

Change the engine oil and oil filter.

Go to Step 11.

|

|

No

|

Go to the next step.

|

|

6

|

INSPECT EXHAUST SYSTEM AND FUEL SELECTION CONCERNS

• Inspect the suspect exhaust system for the following:

-

― Leaks, cracks, or punctures at flanges and gaskets

― Aftermarket accessories and performance modifications

― Exhaust leaks at the HO2S

• Verify with the customer that flex fuel is not being used on a non-flex fuel vehicle.

• Is a concern present?

|

Yes

|

Repair or replace the malfunctioning part according to the inspection results, then go to Step 11.

|

|

No

|

Go to the next step.

|

|

7

|

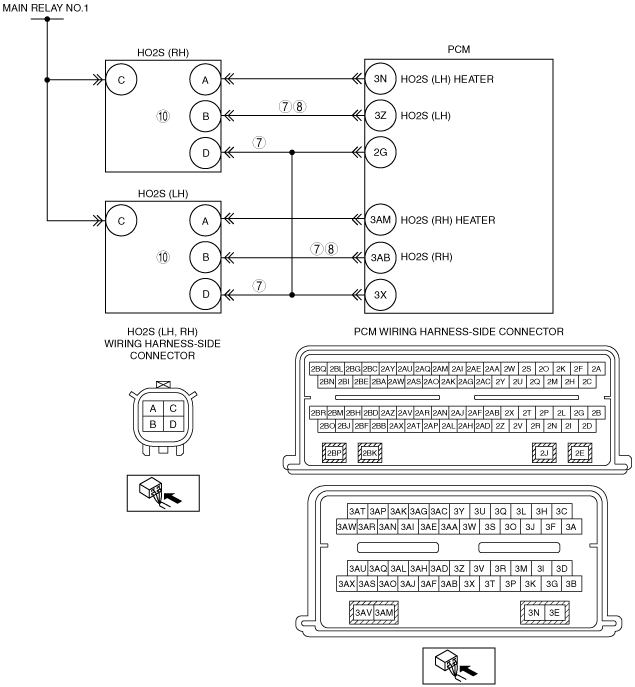

CHECK HO2S CIRCUIT(S) FOR OPEN IN HARNESS

-

Note

-

• Diagnose the suspect sensor indicated by the DTC.

• Verify the harness pins are in the correct location.

• Suspect HO2S connector is disconnected.

• Turn the ignition switch off.

• Disconnect the PCM connector.

• Check the connector (both halves) for any water contamination and replace if necessary.

• Measure the resistance between the following terminals (wiring harness-side):

-

― P2A01:00:

-

• HO2S (RH) terminal B—PCM terminal 3Z

• HO2S (RH) terminal D—PCM terminal 2G

― P2A04:00:

-

• HO2S (LH) terminal B—PCM terminal 3AB

• HO2S (LH) terminal D—PCM terminal 2G

• Is the resistance less than 5 ohm?

|

Yes

|

Go to the next step.

|

|

No

|

Repair for open circuit, then go to Step 11.

|

|

8

|

CHECK HO2S CIRCUIT FOR SHORT TO GROUND

• Suspect HO2S and PCM connectors are disconnected.

• Measure the resistance between the following suspect HO2S terminals:

-

― P2A01:00:

-

• HO2S (RH) terminals B and D (wiring harness-side)

• HO2S (RH) terminal B (wiring harness-side) and body ground

― P2A04:00:

-

• HO2S (LH) terminals B and D (wiring harness-side)

• HO2S (LH) terminal B (wiring harness-side) and body ground

• Is the resistance greater than 10 kilohms?

|

Yes

|

Go to the next step.

|

|

No

|

Repair for short circuit, then go to Step 11.

|

|

9

|

CHECK HO2S CIRCUIT FOR SHORT TO VOLTAGE

• Suspect HO2S and PCM connectors are disconnected.

• Turn the ignition switch to the ON position (engine off).

• Measure the voltage between the following suspect HO2S terminals (wiring harness-side) and body ground:

-

― HO2S (RH) terminal B (P2A01:00)

― HO2S (LH) terminal B (P2A04:00)

• Is there any voltage?

|

Yes

|

Repair for short circuit, then go to Step 11.

|

|

No

|

Go to the next step.

|

|

10

|

CHECK HO2S CIRCUIT CONTINUITY

-

Note

-

• HO2S is displayed as O2S on the scan tool.

• Suspect HO2S and PCM connectors are disconnected.

• Turn the ignition switch off.

• Reconnect the PCM connector.

• Connect a 5 A fused jumper wire between suspect HO2S terminals (wiring harness-side) B and D

• Start the engine and run it at idle.

• Access the PCM and monitor the suspect HO2S signal PID.

-

― O2S11 (VOLT) PID (P2A01:00)

― O2S21 (VOLT) PID (P2A04:00)

• Is the voltage greater than 1 V?

|

Yes

|

Replace the HO2S, then go to the next step.

|

|

No

|

Go to the next step.

(The system is operating normal at this time. The concern may have been caused by a loose or corroded connector.)

|

|

11

|

VERIFY TROUBLESHOOTING OF DTC P2A01:00, P2A04:00 HAS BEEN COMPLETED

• Verify that all disconnected connectors are reconnected.

• Clear the DTC from the PCM memory using the M-MDS.

• Perform the KOEO or KOER self-test.

• Is the PENDING CODE for this DTC present?

|

Yes

|

Repeat the inspection from Step 1.

• If the malfunction recurs, replace the PCM.

Go to the next step.

|

|

No

|

Go to the next step.

|

|

12

|

VERIFY AFTER REPAIR PROCEDURE

• Perform the “AFTER REPAIR PROCEDURE”.

• Are any DTCs present?

|

Yes

|

Go to the applicable DTC inspection.

|

|

No

|

Troubleshooting completed.

|