|

WHEEL ALIGNMENT PRE-INSPECTION

id021100700100

1. Park the vehicle on level ground in an unloaded condition* and with the wheels straight forward.

*Unloaded: Jack and tools are in designated position.

2. Inspect the tire pressures.

3. Inspect the wheel bearing for play. (See WHEEL HUB, STEERING KNUCKLE INSPECTION.) (See WHEEL HUB COMPONENT INSPECTION.)

4. Inspect the wheel for run out.

5. Shake the body and inspect the steering ball joint and suspension ball joint for excessive play.

6. Shake the body and verify that the shock absorbers operate correctly.

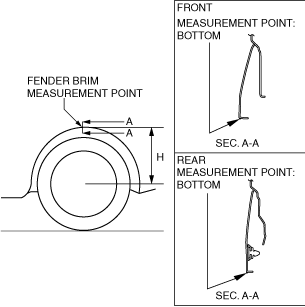

7. Measure dimension H from the edge of the fender to the center of the wheel on both the left and right sides.

a30zzw00000240

|

8. Verify that the difference between dimension H on the left and right sides measured in Step 7 is within the standard.