|

1

|

VERIFY OTHER WARNING LIGHT/INDICATOR LIGHT ON CONDITION

• Switch the main power ON (READY off or on).

• Are any warning lights/indicator lights other than the ABS warning light, brake warning light, TCS/DSC operation indicator light, and the TCS OFF indicator light turned on with the main power switched ON (READY off or on)?

|

Yes

|

Go to Step 4.

|

|

No

|

Communication error is displayed on M-MDS screen:

• Go to the next step.

Communication error is not displayed on M-MDS screen:

• Replace the instrument cluster.

|

|

*2

|

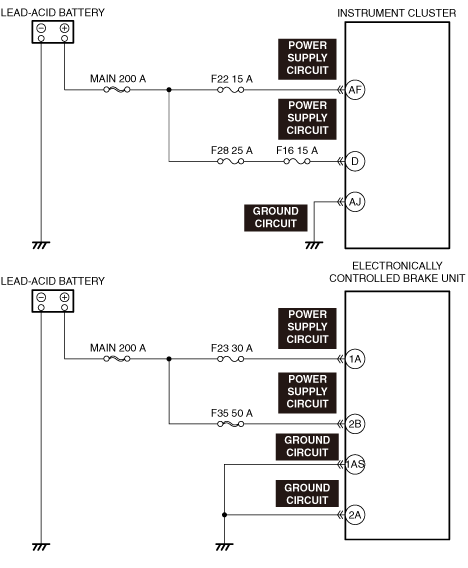

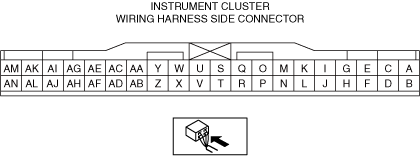

INSPECT INSTRUMENT CLUSTER POWER SUPPLY CIRCUIT FOR SHORT TO GROUND AND OPEN CIRCUIT

• Inspect the applicable circuit for a short to ground and open circuit.

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

*3

|

INSPECT INSTRUMENT CLUSTER GROUND CIRCUIT FOR SHORT TO POWER SUPPLY AND OPEN CIRCUIT

• Inspect the applicable circuit for a short to power supply and open circuit.

• Is the circuit normal?

|

Yes

|

Replace the instrument cluster and perform the repair completion verification. (Open circuit in instrument cluster internal circuit)

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

4

|

VERIFY ELECTRONICALLY CONTROLLED BRAKE UNIT DTCs

• Verify the electronically controlled brake unit DTCs.

• Is a DTC displayed?

|

Yes

|

Repair the malfunctioning location according to the applicable DTC troubleshooting.

|

|

No

|

Communication error is displayed on M-MDS screen:

• Go to the next step.

Communication error is not displayed on M-MDS screen:

• Go to Step 7.

|

|

*5

|

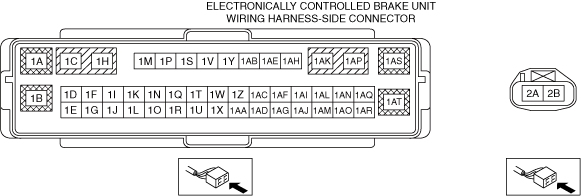

INSPECT ELECTRONICALLY CONTROLLED BRAKE UNIT POWER SUPPLY CIRCUIT FOR SHORT TO GROUND AND OPEN CIRCUIT

• Inspect the applicable circuit for a short to ground and open circuit.

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

*6

|

INSPECT ELECTRONICALLY CONTROLLED BRAKE UNIT GROUND CIRCUIT FOR SHORT TO POWER SUPPLY AND OPEN CIRCUIT

• Inspect the applicable circuit for a short to power supply and open circuit.

• Is the circuit normal?

|

Yes

|

Replace the electronically controlled brake unit and perform the repair completion verification. (Open circuit in electronically controlled brake unit internal circuit)

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

7

|

INSPECT BODY CONTROL MODULE (BCM) FOR MALFUNCTION

• Perform the DTC inspection for the body control module (BCM).

• Is a DTC displayed?

|

Yes

|

Repair the malfunctioning location according to the applicable DTC troubleshooting.

|

|

No

|

Replace the instrument cluster and perform the repair completion verification.

|

|

Repair completion verification

|

VERIFY IF MALFUNCTION CAUSE IS CORRECTED

• Install/connect the part removed/disconnected during the troubleshooting procedure.

• Has the malfunction symptom been eliminated?

|

Yes

|

Complete the symptom troubleshooting.

Explain repair contents to customer.

|

|

No

|

Refer to the CAN (controller area network) malfunction diagnosis flow to inspect for a CAN communication error.

If the CAN communication is normal, perform the diagnosis from Step 1.

|