|

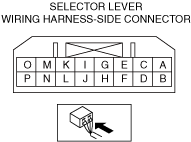

SELECTOR LEVER INSPECTION [A71M]

id0526a7000800

Voltage Inspection

1. Disconnect the negative lead-acid battery terminal. (See NEGATIVE LEAD-ACID BATTERY TERMINAL DISCONNECTION/CONNECTION.)

2. Remove the selector lever knob. (See SELECTOR LEVER REMOVAL/INSTALLATION [A71M].)

3. Remove the shift panel. (See SHIFT PANEL REMOVAL/INSTALLATION.)

4. Connect the negative lead-acid battery terminal. (See NEGATIVE LEAD-ACID BATTERY TERMINAL DISCONNECTION/CONNECTION.)

5. Verify that the voltages of each of the terminals are as indicated in the terminal voltage table (reference).

Terminal Voltage Table (Reference)

a30zzw00000896

|

|

Terminal |

Signal |

Connection |

Measurement condition |

Voltage (V) |

Inspection items |

|---|---|---|---|---|---|

|

A

|

IG1

|

IG1 relay No. 2

|

Main power ON (READY off or on)

|

B+

|

• Wiring harness (A—IG1 relay No. 2 C)

|

|

Main power OFF

|

1.0 or less

|

||||

|

B

|

CAN_L_PBLC1

|

CAN related module

|

Because this terminal is for communication, determination using terminal voltage inspection is not possible. Perform inspection using the DTC inspection.

|

||

|

C

|

BATT

|

Lead-acid battery

|

Continuous

|

B+

|

• Wiring harness (C—lead-acid battery)

|

|

D

|

CAN_H_PBLC1

|

CAN related module

|

Because this terminal is for communication, determination using terminal voltage inspection is not possible. Perform inspection using the DTC inspection.

|

||

|

E

|

—

|

—

|

—

|

—

|

—

|

|

F

|

CAN_L_PBLC2

|

CAN related module

|

Because this terminal is for communication, determination using terminal voltage inspection is not possible. Perform inspection using the DTC inspection.

|

||

|

G

|

GND

|

ground point

|

Continuous

|

1.0 or less

|

• Wiring harness (G—ground point)

|

|

H

|

CAN_H_PBLC2

|

CAN related module

|

Because this terminal is for communication, determination using terminal voltage inspection is not possible. Perform inspection using the DTC inspection.

|

||

|

I

|

Indicator_R

|

Indicator

|

R position

|

1.0 or less

|

• Wiring harness (I—indicator D)

|

|

Other than R position

|

B+

|

||||

|

J

|

—

|

—

|

—

|

—

|

—

|

|

K

|

IND_Ilumi_power

|

Indicator

|

Main power ON (READY off or on)

|

B+

|

• Wiring harness (K—indicator A)

|

|

Main power OFF

|

|

|

|||

|

L

|

Indicator_N

|

Indicator

|

N position

|

1.0 or less

|

• Wiring harness (L—indicator E)

|

|

Other than N position

|

B+

|

||||

|

M

|

Indicator_P

|

Indicator

|

P position

|

1.0 or less

|

• Wiring harness (M—indicator C)

|

|

Other than P position

|

B+

|

||||

|

N

|

—

|

—

|

—

|

—

|

—

|

|

O

|

Back_Ilumi_power

|

Indicator

|

Main power ON (READY off or on)

|

B+

|

• Wiring harness (O—indicator B)

|

|

P

|

Indicator_D

|

Indicator

|

D position

|

1.0 or less

|

• Wiring harness (P—indicator F)

|

|

Other than D position

|

B+

|

||||

Operation Inspection

1. Switch the main power ON (READY on).

2. Inspect the selector lever as follows:

L.H.D.

a30zzw00000900

|

R.H.D.

a30zzw00005650

|