ELECTRIC MOTOR SPEED SENSOR INSPECTION

id304000101500

-

Warning

-

<<High voltage>>

• If the necessary measures are not taken before servicing an electric vehicle, it could cause electrical shock and result in serious injury or, in the worst case, death. Before servicing the electric vehicle, refer to [HIGH VOLTAGE SERVICE CAUTIONS] in the general information and implement the necessary measures. (See

HIGH VOLTAGE SERVICE CAUTIONS.)

High Voltage Part Inspection And Removal/Installation Notes

-

Warning

-

<<High voltage>>

• If necessary measures such as wearing the correct protective gear are not taken when inspecting or removing/installing the high voltage parts, it could cause electrical shock and result in serious injury or, in the worst case, death.

• Before inspecting or removing/installing the high voltage parts, refer to [HIGH VOLTAGE SERVICE CAUTIONS] in the general information and [High Voltage Part Inspection and Removal/Installation Notes] of the high voltage system service cautions and implement the necessary measures and preparations. (See

HIGH VOLTAGE SERVICE CAUTIONS.) (See

HIGH VOLTAGE SYSTEM SERVICE CAUTIONS.)

Resistance Inspection

-

Caution

-

• Because the electric motor is hot after driving, the resolver sensor resistance value does not become a value according to the ambient temperature. Therefore, leave the vehicle for 1 day or more after driving and perform the inspection with a stable electric motor internal temperature.

1. Leave the vehicle for 1 day or more.

2. Wear insulating gloves and remove the service plug.

(See SERVICE PLUG REMOVAL/INSTALLATION.)

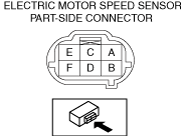

3. Disconnect the electric motor speed sensor connector.

4. Measure the resistance between the following resolver sensor terminals.

-

Electric motor speed sensor resistance (standard)

-

• Between terminal A and terminal B (energizing coil): 9.5 — 15.5 Ω (20 °C {68 °F})

• Between terminal C and terminal D (detection coil sin): 13 — 27 Ω (20 °C {68 °F})

• Between terminal E and terminal F (detection coil cos): 13 — 27 Ω (20 °C {68 °F})

-