HIGH VOLTAGE BATTERY COOLING CONTROL

id304000200900

Outline

• The high voltage battery generates heat and becomes hot when charged and discharged. In addition, if a high temperature condition continues, the high voltage battery will largely deteriorate.

• When the high voltage battery is hot, the PCM requests the heat pump unit to perform cooling until the high voltage battery temperature decreases to an appropriate level using the refrigerant used for the climate control system.

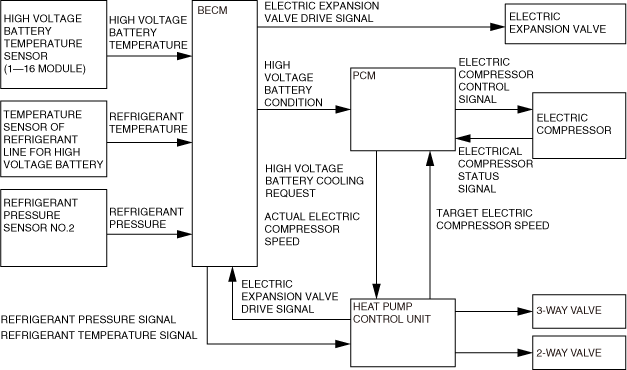

Block Diagram

Operation

• The BECM sends the high voltage battery temperature detected by the high voltage battery module temperature sensor to the PCM via CAN communication.

• The BECM sends the refrigerant pressure and temperature of the high voltage battery cooling system to the heat pump control unit via CAN communication.

• The PCM determines the necessity of high voltage battery cooling based on the high voltage battery temperature received from the BECM, and sends a cooling request to the heat pump control unit via CAN communication.

• The climate control unit drives the electric expansion valve and the 3-way valve for switching the high voltage battery cooling based on the signal received from the PCM and the air conditioning request received from the heat pump control unit to adjust the refrigerant flow on the high voltage battery cooling side and the air conditioning side. (See

FULL-AUTO AIR CONDITIONER SYSTEM [FULL-AUTO AIR CONDITIONER].)

• The PCM drives the electric compressor based on the requested compressor speed received from the heat pump control unit.

• The BECM drives the electric expansion valve based on the requested electric expansion valve opening angle received from the heat pump control unit.

• The BECM cools the high voltage battery when the high voltage battery temperature is 40 °C {104 °F} or more, such as after driving under a heavy load, and the user selects cooling on the center display after the EV system stops.