|

Item (definition)

|

Unit/Condition

|

Condition/Specification (Reference)

|

Inspection item(s)

|

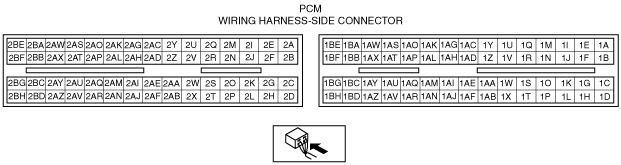

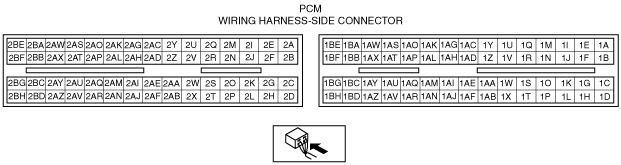

PCM terminal

|

|

AC_REQ

(Refrigerant pressure switch (high, low)

|

Off/On

|

• Refrigerant pressure is more than the specification or less than the specification. (Refrigerant pressure switch (high, low) is off.): Off

• Except above: On

|

• Refrigerant pressure switch (high, low)

• A/C amplifier

|

1AU

|

|

ACCS

(A/C relay)

|

Off/On

|

• A/C relay is ON: On

• A/C relay is OFF: Off

|

• The following PIDs

-

- CPP*1, CPP/PNP*1, ECT, RPM, TP, TR*2, AC_REQ, COLP

|

1I

|

|

AFR

(Air/fuel ratio)

|

-

|

• Idle after warm-up: Approx. 1

|

• A/F sensor

|

2AD

|

|

AFR_ACT

(Actual air/fuel ratio)

|

-

|

• Idle after warm-up: Approx. 1

|

• A/F sensor

• HO2S

|

-

|

|

ALTF

(Generator field coil control duty value)

|

%

|

• Ignition switch is turned to the ON position: 0%

• Idle, E/L is operating: Duty value increases.

|

• Generator

|

2AI

|

|

ALTT V

(Generator output voltage)

|

V

|

• Idle (no E/L): Approx. 14 V (This is an internal calculation value and differs from the terminal voltage.)

|

• Generator

|

2AJ

|

|

APP

(Accelerator pedal position)

|

%

|

• Accelerator pedal released: 0%

• Accelerator pedal depressed: 100%

|

• The following PIDs

-

- APP1, APP2

|

1AO, 1AP

|

|

APP1

(APP sensor No.1)

|

%

|

• Accelerator pedal released: Approx. 32%

• Accelerator pedal depressed: Approx. 78%

|

• APP sensor

|

1AO

|

|

V

|

• Accelerator pedal released: Approx. 1.6 V

• Accelerator pedal depressed: Approx. 3.9 V

|

|

APP2

(APP sensor No.2)

|

%

|

• Accelerator pedal released: Approx. 21%

• Accelerator pedal depressed: Approx. 67%

|

• APP sensor

|

1AP

|

|

V

|

• Accelerator pedal released: Approx. 1.0 V

• Accelerator pedal depressed: Approx. 3.4 V

|

|

ARPMDES

(Target engine speed)

|

RPM

|

• Indicate the target engine speed.

|

• The following PIDs

-

- CPP*1, CPP/PNP*1, ECT, IAT, RPM, TP, MAF, MAP, VSS, AC_REQ, COLP

|

-

|

|

BARO

(Barometric pressure)

|

Pa

|

• Ignition switch is turned to the ON position: Indicate the barometric pressure

|

-

|

-

|

|

V

|

• Ignition switch is turned to the ON position (at sea level): 4.1 V

|

|

BOO

(Brake switch)

|

Off/On

|

• Brake pedal depressed: On

• Brake pedal released: Off

|

• Brake switch

|

1AB, 1AF

|

|

BPA*5

(Brake pressure applied switch)

|

Off/On

|

• Brake pedal depressed: On

• Brake pedal released: Off

|

• Brake switch

|

-

|

|

CATT11_DSD

(Catalyst temperature)

|

°C

|

°F

|

• Ignition switch is turned to the ON position: Indicate the catalyst temperature

|

-

|

-

|

|

CHRGLP

(Generator warning light)

|

Off/On

|

• Idle, Generator warning light illuminate: On

• Idle, Generator warning light not illuminate: Off

|

• Generator warning light

|

-

|

|

COLP

(Refrigerant pressure switch (middle))

|

OFF/ON

|

• Refrigerant pressure is more than the specification. (Refrigerant pressure switch (middle) is on.): On

• Refrigerant pressure is less than the specification. (Refrigerant pressure switch (middle) is off.): Off

|

• Refrigerant pressure switch (middle)

|

1J

|

|

CPP*1

(Clutch pedal position)

|

Off/On

|

• Clutch pedal depressed: On

• Clutch pedal released: Off

|

• CPP switch

|

1D

|

|

CPP/PNP*1

(Shift lever position)

|

Drive/Neutral

|

• Neutral: Neutral

• Other than neutral: Drive

|

• Neutral switch

|

1X

|

|

DTCCNT

(Number of DTC detected)

|

-

|

• Number of DTCs stored

|

-

|

-

|

|

ECT

(Engine coolant temperature)

|

°C

|

°F

|

• Ignition switch is turned to the ON position: Indicate the ECT

|

• ECT sensor

|

2AH

|

|

V

|

• ECT is 20 °C {68 °F}: Approx. 3.0 V

• ECT is 80 °C {176 °F}: Approx. 0.9 V

|

|

EQ_RAT11

(Actual lambda signal)

|

-

|

• Idle after warm-up: Approx. 1

|

• A/F sensor

|

-

|

|

EQ_RAT11_DSD

(Target lambda)

|

-

|

• Target lambda (Excess air factor = supplied air amount / theoretical air/fuel ratio)

|

• A/F sensor

|

-

|

|

ETC_ACT

(Throttle control)

|

°

|

• Accelerator pedal released: Approx. 0 °

• Accelerator pedal depressed: Approx. 94.5 °

|

• TP sensor

|

-

|

|

ETC_DSD

(Throttle control desired)

|

%

|

• Indicate the target throttle valve opening ratio

|

• The following PIDs

-

- APP, RPM

|

-

|

|

°

|

• Indicate the target throttle valve opening angle

|

|

EVAPCP

(Purge solenoid valve duty value)

|

%

|

• Ignition switch is turned to the ON position: 0%

• Increase the engine speed (after warm-up): Duty value rises

|

• The following PIDs

-

- ECT, IAT, RPM, TP, MAF, O2S11, O2S12, BOO, VPWR

• Purge solenoid valve

|

2C

|

|

FAN1

(Cooling fan relay No.1 control signal)

|

Off/On

|

• During test mode

CTP: Off

WOT: On

|

• The following PIDs

-

- ECT, test, TP

|

1M

|

|

FAN2

(Cooling fan relay No.2 control signal)

|

Off/On

|

• During test mode

CTP: Off

WOT: On

|

• The following PIDs

-

- ECT, test, TP

|

1N

|

|

FAN3

(Cooling fan relay No.3 control signal)

|

Off/On

|

• During test mode

CTP: Off

WOT: On

|

• The following PIDs

-

- ECT, test, TP

|

1R

|

|

FP

(Fuel pump relay)

|

Off/On

|

• Ignition switch is turned to the ON position and a certain period has elapsed: Off

• Cranking: On

• Idle: On

|

• Fuel pump relay

|

1H

|

|

FUELPW

(Fuel injector duration)

|

sec

|

• Idle: Approx. 2.0 ms

|

• The following PIDs

-

- CPP*1, CPP/PNP*1, ECT, IAT, RPM, TP, MAF, O2S11, O2S12, MAP, VSS, TR*2, BOO, AC_REQ, COLP, VPWR

|

2BB, 2BC, 2BD, 2AZ

|

|

FUELSYS

(Fuel system status)

|

OL/CL/

OL-Drive/

OL-Fault/

CL-Fault

|

• Idle after warm-up: CL

|

• The following PIDs

-

- CPP*1, CPP/PNP*1, ECT, IAT, RPM, TP, MAF, O2S11, O2S12, MAP, VSS, TR*2, BOO, AC_REQ, COLP, VPWR

|

-

|

|

GENVDSD

(Target generator voltage)

|

V

|

• Indicate the target generated voltage

|

• The following PIDs

-

- ECT, IAT, RPM, VSS, ALTT V, VPWR

• Generator

|

-

|

|

HTR11

(A/F sensor heater control)

|

Off/On

|

• Ignition switch is turned to the ON position: Off

• Idle: On

|

• The following PIDs

-

- ECT, IAT, RPM, TP, MAF, MAP, VPWR

|

2BG

|

|

HTR12

(HO2S heater control)

|

Off/On

|

• Ignition switch is turned to the ON position: Off

• Idle: On

|

• The following PIDs

-

- ECT, IAT, RPM, TP, MAF, MAP, VPWR

|

2BE

|

|

IAT

(Intake air temperature)

|

°C

|

°F

|

• Ignition switch is turned to the ON position: Indicate the IAT

|

• IAT sensor

|

1AT

|

|

V

|

• IAT is 20 °C {68 °F}: Approx. 2.4 V

• IAT is 60 °C {140 °F}: Approx. 0.9 V

|

|

IMRC*4

(Variable tumble control)

|

Off/On

|

• ECT less than 60 °C {142 °F} and engine speed less than 3,750 rpm: On

• ECT 60 °C {142 °F} or more and engine speed 3,750 rpm or more: Off

|

• The following PIDs

-

- ECT, RPM, TP

|

2I

|

|

IMTV

(Variable intake air control)

|

Off/On

|

• Engine speed is less than 4,750 rpm: On

• Engine speed is 4,750 rpm or more: Off

|

• The following PIDs

-

- RPM

|

2J

|

|

INGEAR

(Gears are engaged)

|

Off/On

|

MT

• When the following conditions are satisfied: On

-

- Other than neutral

-

- Clutch pedal released

• Except above: Off

|

• CPP switch

• Neutral switch

|

1D,1X

|

|

AT

• Driving range: On

• Except above: Off

|

• TR switch

|

-

|

|

IVS

(CTP condition)

|

Idle/Off Idle

|

• Idle: Idle

• Other than idle: Off Idle

|

• The following PIDs

-

- TP

|

-

|

|

KNOCKR

(Knocking retard)

|

°

|

• Ignition switch is turned to the ON position: 0 °

• Idle: 0 °

|

• KS

|

2U

|

|

LOAD

(Engine load)

|

%

|

• Idle after warm-up: Approx. 23%

|

• The following PIDs

-

- MAP, IAT, MAF, RPM

|

-

|

|

LONGFT1

(Long term fuel trim)

|

%

|

• Idle after warm-up: Approx. -15-+15%

|

• The following PIDs

-

- CPP*1, CPP/PNP*1, ECT, IAT, RPM, TP, MAF, O2S11, O2S12, MAP, VSS, TR*2, BOO, AC_REQ, COLP, VPWR

|

-

|

|

MAF

(Mass air flow)

|

g/sec

|

• Ignition switch is turned to the ON position: Approx. 0 g/s

• Idle: Approx. 4.0 g/s

|

• MAF sensor

|

1AK

|

|

V

|

• Ignition switch is turned to the ON position: Approx. 0.7 V

• Idle: Approx. 1.4 V

|

|

MAP

(Manifold absolute pressure)

|

Pa

|

• Ignition switch is turned to the ON position: Indicate the MAP

|

• MAP sensor

|

2AG

|

|

V

|

• Ignition switch is turned to the ON position (at sea level): 4.1 V

• Idle after warm-up: Approx. 1.2 V

|

|

MIL

(Malfunction indicator lamp)

|

Off/On

|

• Idle, MIL illuminate: On

• Idle, MIL not illuminate: Off

|

• MIL

|

-

|

|

MIL_DIS

(Travelled distance since MIL illuminated)

|

km

|

mile

|

Travelled distance since MIL illuminated

|

-

|

|

O2S11

(A/F sensor)

|

A

|

• Idle after warm-up: Approx. 0 mA

|

• A/F sensor

|

2AD

|

|

O2S12

(HO2S)

|

V

|

• Idle after warm-up: Alternates between 0 and 1.0 V

|

• HO2S

|

2Q

|

|

PSP

(PSP switch)

|

Low/High

|

• Steering wheel at straight ahead position: Low

• While turning steering wheel: High

|

• PSP switch

|

2T

|

|

RFCFLAG

(PCM adaptive memory produce verification)

|

Not Learnt/

Learnt

|

• Idle (after running PCM adaptive memory procedure drive mode): Learnt

• Right after the negative battery cable is disconnected (before running PCM adaptive memory procedure drive mode): Not Learnt

|

• Verify after repair procedure

|

-

|

|

RO2FT1

(HO2S fuel trim)

|

-

|

• Idle after warm-up: Approx. 0

|

• The following PIDs

-

- O2S12

|

-

|

|

RPM

(Engine speed)

|

RPM

|

• When the engine is running: Indicate the engine speed

|

• CKP sensor

|

2W

|

|

SCCS*5

(Cruise control switch)

|

V

|

• ON OFF switch pressed in: Approx. 0 V

• CANCEL switch pressed in: Approx. 1.1 V

• SET/- switch pressed in: Approx. 3.1 V

• RES/+ switch pressed in: Approx. 4.2 V

• Except above: Approx. 5.0 V

|

• Cruise control switch

|

1AQ

|

|

SEGRP

(EGR control)

|

-

|

• Ignition switch is turned to the ON position: 0 Step

• Idle: 0 Step

• Engine speed is 1,200-4,200 rpm: 0-52 Step

|

• EGR valve

|

2K, 2G, 2L, 2H

|

|

SEGRP DSD

(EGR valve position desired)

|

%

|

• Ignition switch is turned to the ON position: 0%

• Idle: 0%

• Engine speed is 1,200-4,200 rpm: 0-100%

|

• The following PIDs

-

- MAF, TP, ECT, RPM, VSS

|

-

|

|

SELTESTDTC

(Diagnostic trouble codes)

|

-

|

• Indicate the diagnostic trouble codes

|

-

|

-

|

|

SHRTFT1

(Short term fuel trim (front))

|

%

|

• Idle after warm-up: -25- 25%

|

• The following PIDs

-

- CPP*1, CPP/PNP*1, ECT, IAT, RPM, TP, MAF, O2S11, O2S12, MAP, VSS, TR*2, BOO, AC_REQ, COLP, VPWR

|

-

|

|

SHRTFT12

(Short term fuel trim (rear))

|

%

|

• Idle after warm-up: Approx. 99%

|

• The following PIDs

-

- CPP*1, CPP/PNP*1, ECT, IAT, RPM, TP, MAF, O2S11, MAP, VSS, TR*2, BOO, AC_REQ, COLP, VPWR

|

-

|

|

SPARKADV

(Ignition timing)

|

°

|

• Indicate the ignition timing

|

• The following PIDs

-

- CPP*1, CPP/PNP*1, ECT, IAT, RPM, TP, MAF, KNOCKR, TR*2, BOO, AC_REQ, COLP

|

2S

|

|

test

(Test mode)

|

Off/On

|

• Test mode On: On

• Test mode Off: Off

|

-

|

-

|

|

TIRESIZE

(Tire revolution per mile)

|

rev/mile

|

• Indicate the tire revolution per a mile

|

-

|

|

TP REL

(Throttle position signal (relative value))

|

%

|

• Accelerator pedal released: Approx. 10%

• Accelerator pedal depressed: Approx. 81%

|

• The following PIDs

-

- TP1, TP2

|

-

|

|

TP1

(TP sensor No.1)

|

%

|

• Accelerator pedal released: Approx. 10%

• Accelerator pedal depressed: Approx. 90%

|

• TP sensor

|

2AK

|

|

V

|

• Accelerator pedal released: Approx. 0.5 V

• Accelerator pedal depressed: Approx. 4.5 V

|

|

TP2

(TP sensor No.2)

|

%

|

• Accelerator pedal released: Approx. 10%

• Accelerator pedal depressed: Approx. 90%

|

• TP sensor

|

2AL

|

|

V

|

• Accelerator pedal released: Approx. 4.5 V

• Accelerator pedal depressed: 0.5 V

|

|

TPCT

(TP sensor voltage at CTP)

|

V

|

• Ignition switch is turned to the ON position: Approx. 0.5 V

|

• The following PIDs

-

- TP1, TP2

|

-

|

|

VPWR

(Battery positive voltage)

|

V

|

• Indicate the battery voltage

|

• Battery

|

1BA

|

|

VSS

(Vehicle speed)

|

KPH

|

• Vehicle running: Indicate the vehicle speed

|

• ABS, DSC HU/CM

• TCM

|

1AM, 1AI

|

|

VT ACT1*3

(Actual valve timing)

|

°

|

• Idle: Approx. 0 °

• Racing: 0-25 °

|

• The following PIDs

-

- ECT, RPM, TP, MAF

• OCV

|

2E

|

|

VT DIFF1*3

(Difference between target valve timing and actual valve timing)

|

°

|

• Idle: 0 °

|

• The following PIDs

-

- ECT, RPM, TP, MAF

• OCV

|

-

|

|

VT DUTY1*3

(OCV control)

|

%

|

• Idle: Approx. 10%

|

• The following PIDs

-

- ECT, RPM, TP, MAF

|

2E

|