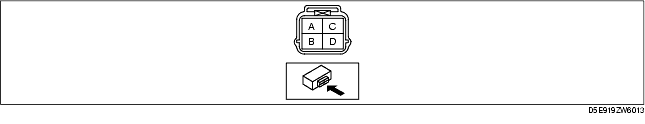

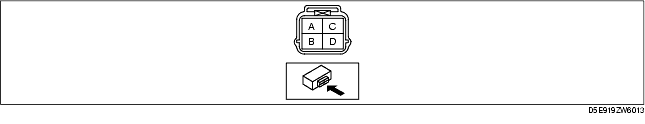

1. Remove the headlight cleaner relay with the connector still connected.

2. Measure the voltage at each terminal (other than terminal C).

3. Remove the battery cover.

4. Disconnect the negative battery cable. (See BATTERY REMOVAL/INSTALLATION [L8, LF].)

5. Verify that continuity at terminal C is as indicated in the Terminal Voltage Table (Reference).

|

Terminal

|

Signal name

|

Connected to

|

Measured condition

|

Voltage (V)/Continuity

|

Inspection item(s)

|

|

|---|---|---|---|---|---|---|

|

A

|

Headlight cleaner motor output

|

Headlight cleaner motor

|

Headlight cleaner activated (auto-operation or manual operation activated)

|

Alternates between 1.0 or less and B+

|

• Headlight relay

(SeeRELAY INSPECTION.)

• Wiper and washer switch (SeeWIPER AND WASHER SWITCH INSPECTION.)

• Headlight cleaner motor (SeeHEADLIGHT CLEANER MOTOR INSPECTION.)

• Related wiring harnesses

|

|

|

Except above

|

B+

|

|||||

|

B

|

Washer motor output

|

Wiper and washer switch

|

Turn the ignition switch to the ON position.

|

Turn the washer switch to the OFF position.

|

1.0 or less

|

• Headlight relay

(SeeRELAY INSPECTION.)

• Wiper and washer switch (SeeWIPER AND WASHER SWITCH INSPECTION.)

• Related wiring harnesses

|

|

Turn the washer switch to the ON position.

|

B+

|

|||||

|

C

|

GND

|

Body ground

|

Under any condition: Inspect for continuity to ground.

|

Continuity detected

|

• GND

• Related wiring harnesses

|

|

|

D

|

Headlight

|

Headlight relay

|

Light switch at ON position.

|

B+

|

• Headlight relay

(SeeRELAY INSPECTION.)

• Related wiring harnesses

|

|

|

Except above

|

1.0 or less

|

|||||